BMS current detection unit automatic calibration device and calibration method

A current detection unit and automatic calibration technology, applied in the direction of measuring devices, measuring electrical variables, instruments, etc., can solve the problems of low production efficiency, complex process, large calibration error, etc., and achieve high production efficiency, simple equipment, and saving rework. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to allow those skilled in the art to better understand the technical solution of the present invention, the present invention will be further elaborated below.

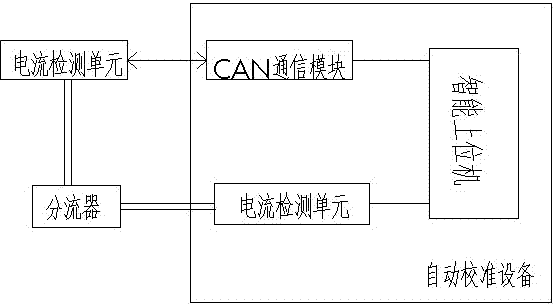

[0017] An automatic calibration device for a BMS current detection unit, including a host computer, a program-controlled constant current source and a communication module. A shunt is provided between the unit and the program-controlled constant current source, and the shunts are connected with the current detection unit and the program-controlled constant current source by means of current sampling lines. The upper computer is based on a desktop computer or a notebook computer, runs preset functional software, and mainly sends control commands to the program-controlled constant current source and exchanges data with the communication module to complete each step of the matching and calibration process. At the same time, the upper computer also has automatic calculation. The function of error offset P,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com