potato harvester

A harvester and potato technology, applied to digging harvesters, harvesters, excavators, etc., can solve the problems of single control mode and inflexible control mode of the self-locking control structure of the stacker, and achieve flexible structure and convenient operation. The effect of secondary collection and improvement of labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

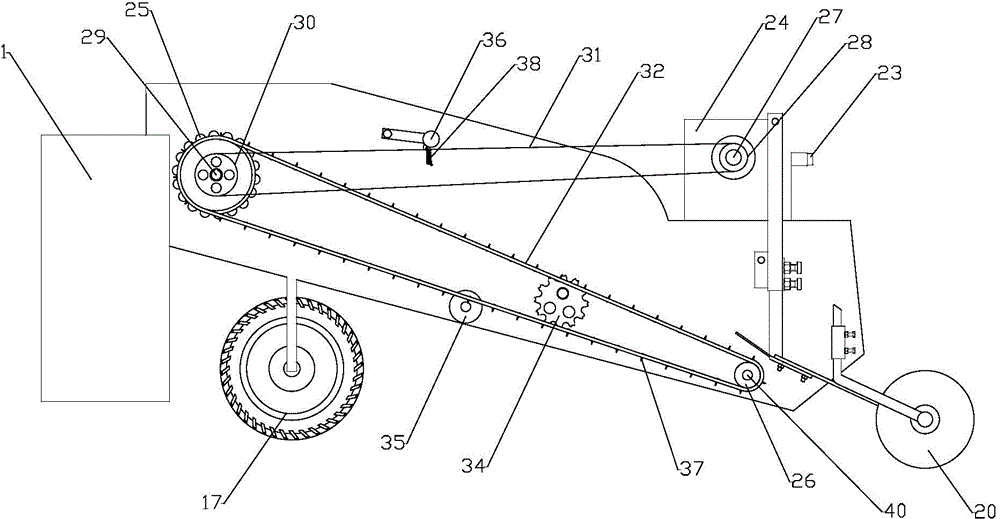

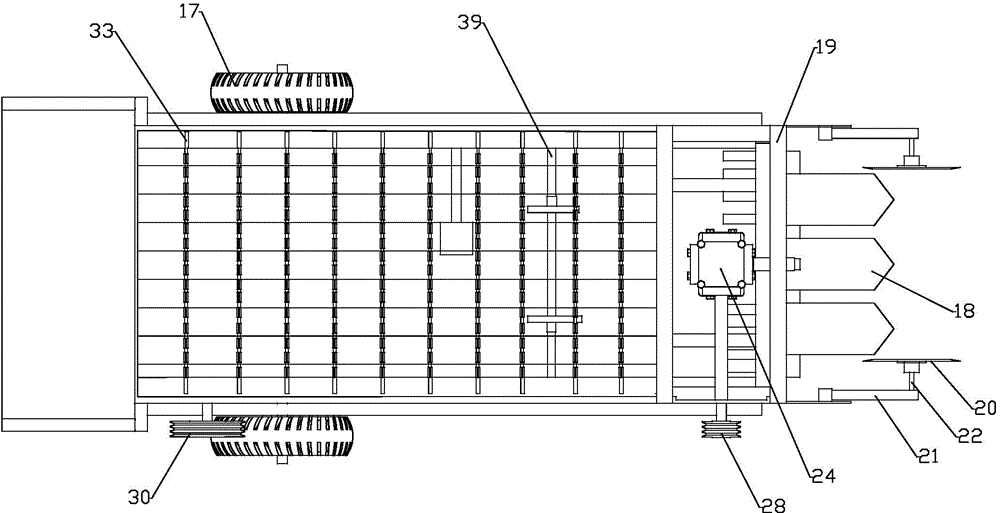

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Shown:

[0039] This potato harvester comprises a body, the two sides of the body are provided with ground wheels 17, the front end of the body is provided with a traction device and an excavating device, and the rear end of the body is provided with a collection device, which is connected by a conveying device between the collection device and the excavation device.

[0040] The traction device includes a traction frame fixed on the machine body and a three-point suspension device installed on the traction frame.

[0041] Excavator comprises the shovel frame 19 that is installed on body front end and the digging shovel 18 that is installed on the shovel frame 19, and support 21 is installed symmetrically on the both sides of shovel frame, and soil cutting disc 20 is symmetrically installed on support 21, and soil cutting disc 20 is connected on the bracket 21 by the shaft 22.

[0042]The conveying ...

Embodiment 2

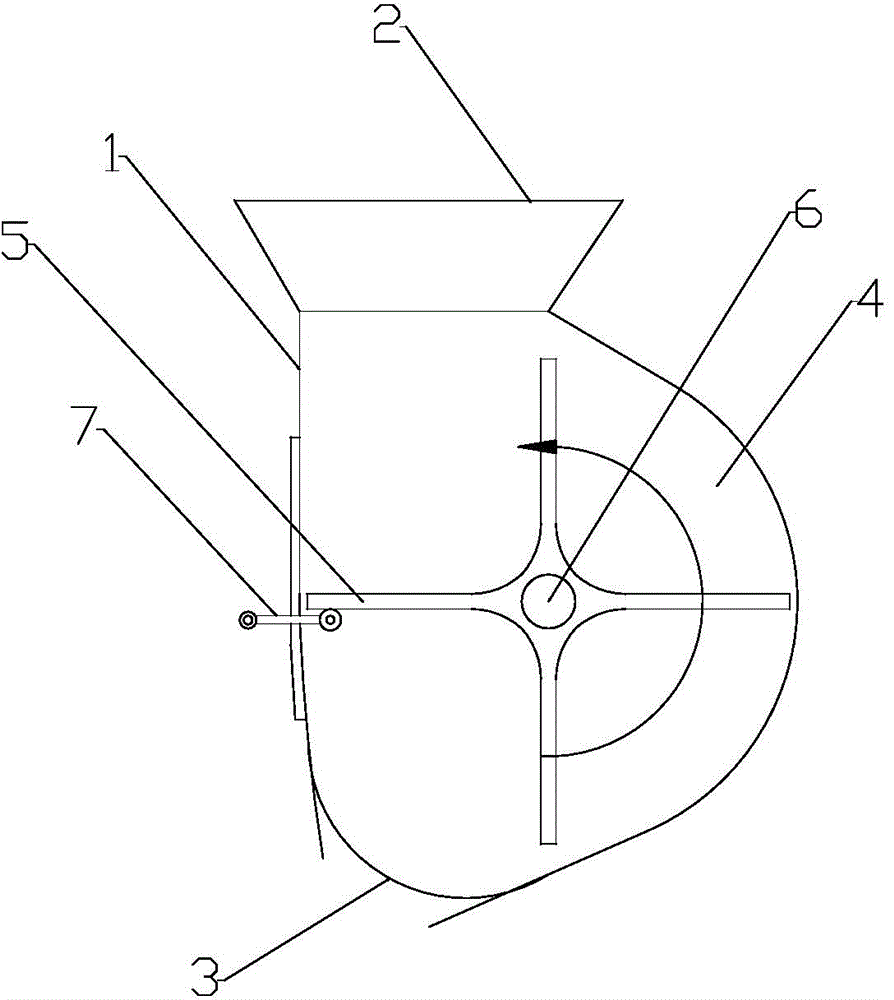

[0048] Such as Figure 6 and Figure 7 Shown:

[0049] Different from Embodiment 1, the switch device of the potato divider is a baffle plate 7 installed on the collection box, and the working process of the directional stacking device is as follows: the switch control device is a stroke control device, and the stroke control device includes a cam 11. The rotating shaft is connected to the ground wheel 12 of the potato harvester through the transmission device; the periphery of the cam 11 is lapped to the switch system, and the switch system is connected to the switch device of the potato divider. Transmission device comprises a transmission shaft 13 that bevel gear is installed, and transmission shaft 13 is connected to the ground wheel 12 of potato harvester through sprocket transmission device, and the output shaft of bevel gear box is equipped with cam 11; Switch system comprises connecting rod 10, connects Bar 10 is provided with slide block 9, and slide block 9 can sli...

Embodiment 3

[0052] Such as Figure 8 Shown:

[0053] Different from Embodiment 1 and Embodiment 2, the switch device of the potato divider is a baffle plate 7 installed on the collection box, and the working process of the directional stacking device is as follows: the switch control device is a weight control device, and the weight control device includes a counterweight Block 14, fixed shaft 15 and connecting rod 16, fixed connection between counterweight 14 and baffle plate 7, be connected to connecting rod 16 through fixed shaft 15, counterweight 14 and baffle plate 7 can rotate around fixed shaft 15, connect One end of the rod 16 is connected to the fixed shaft 15 , and the other end of the connecting rod 16 is installed on the collection box 1 .

[0054] The counterweight control device is based on the principle of leverage. Since the counterweight 14 has a certain weight, when the potato pieces in the temporary potato collection area reach a certain weight, the pressure of the pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com