Cold air blast strip fixing equipment for producing fresh wet noodles

A technology of cold air setting and fresh wet noodles, which is applied in application, food preparation, dough processing, etc. It can solve the problems of enhanced microbial growth and reproduction, threat to product safety and quality, and cracks on the surface of noodles to achieve extended shelf life and strong gluten. , good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

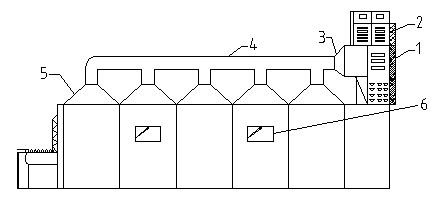

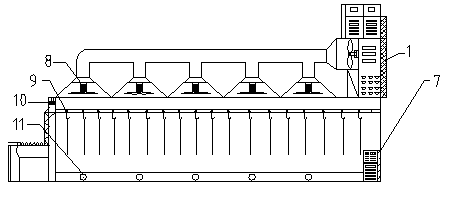

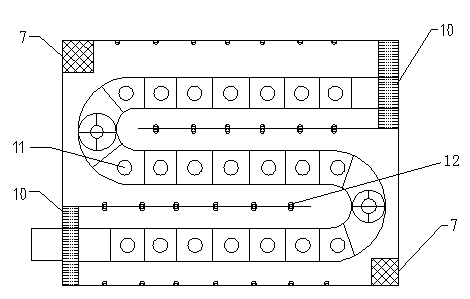

[0016] Referring to the accompanying drawings, the present embodiment includes a drying box 5, a transmission system 9, a dehumidifier 7, a refrigerator 1, a sterilizing device, a ventilation system and a control box (not shown in the figure), and the two sides of the drying box 5 are provided with There is a box door for noodles to come in and out, an air curtain machine 10 is provided on the inside of the box door, and a moisture discharge hole 11 is provided at the bottom of the drying box 5; the transmission system 9 is installed in the drying box 5 in the shape of "S " type route layout, the top of the transmission system 9 is facing the ventilation system, and the bottom is facing the moisture discharge hole 11; the dehumidifier 7 is located in the drying box 5 and communicated with the moisture discharge hole 11; the refrigerator 1 is located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com