Pollen pini circulation airflow screening and impurity removing device and method

A technology of circulating airflow and pine pollen, which is applied in chemical instruments and methods, separating solids from solids by airflow, and separating solids, etc., can solve the problems of low screening efficiency and poor separation effect, and achieve screening efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

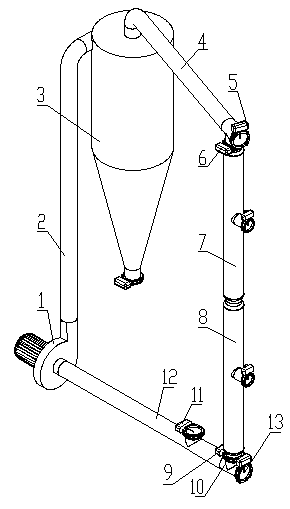

[0020] The first embodiment: a kind of equipment for screening and removing impurities by circulating air flow of pine pollen.

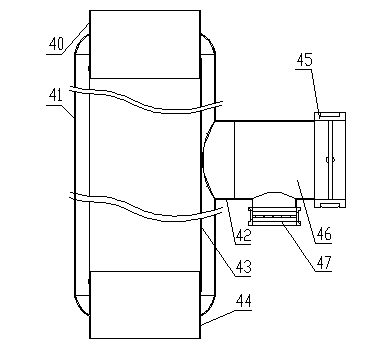

[0021] see figure 1 and figure 2 , the pine pollen circulating airflow screening and impurity removal equipment, including fan 1, circulation pipeline Ⅰ 2, cyclone dust collector 3, circulation pipeline Ⅱ 4, circulation cut-off valve 6, sieve cylinder 7, sieve cylinder 8, regulating valve 9, air inlet Tee 10, Circulation Pipeline Ⅲ12, the above components are fan 1 outlet, Circulation Pipeline Ⅰ2, Cyclone Dust Collector 3 Air Inlet, Cyclone Dust Collector 3 Air Outlet, Circulation Pipeline Ⅱ4, Circulation Stop Valve 6, Screen Drum 7 Feed Pipe 40, sieve cylinder 7 discharge pipe 44, sieve cylinder 8 feed pipe 40, sieve cylinder 8 discharge pipe 44, regulating valve 9, air inlet tee 10, circulation pipeline III 12, fan 1 inlet are connected in order to form a cycle channel; there is a slag discharge port on the circulation pipeline Ⅱ4, and a slag di...

no. 2 example

[0023] The second embodiment: a method for sieving and removing impurities by circulating airflow of pine pollen.

[0024] This embodiment adopts the pine pollen circulating airflow screening and impurity removal equipment of the first embodiment to carry out the screening and impurity removal method for pine pollen, including the following steps:

[0025] S1. Adjustment and start-up of the initial state of the equipment: close the slag discharge valve 5, the air inlet valve 13 and the feeding valve 11, open the circulation cut-off valve 6, start the fan 1, open the air inlet valve 13 after the fan 1 is started, and adjust the regulating valve 9 The opening of the screen is between 5% and 40%, so that the inside of the screen drum is in a positive pressure state of 100-1000Pa;

[0026] S2, feeding: open the feeding valve 11 and add pine pollen with a moisture content of 8%, the amount of pine pollen added is 10% of the volume of the circulation channel, and the pine pollen ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com