PET (polyethylene terephthalate) air flotation separation device

A sorting device and air flotation technology, applied in the field of sorting label paper, can solve the problems of lack of competitiveness of enterprises, difficulty in controlling product quality, low sorting efficiency, etc., and achieve the effect of enhancing market competitiveness and controlling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the PET air flotation separation apparatus according to the embodiment of the present invention will be described in detail with reference to the drawings.

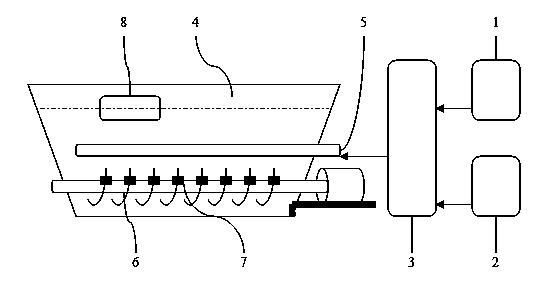

[0024] figure 1 It is a schematic diagram of a PET air flotation separation device according to an embodiment of the present invention. Such as figure 1 As shown, it includes booster pump 1, dissolved air tank 2, air compressor 3, air flotation cleaning tank 4 and other major equipment.

[0025] There is a dissolved air water injection pipe 5 on both sides of the inner tank bottom of the air flotation cleaning tank 4, above the said dissolved air water injection pipe 5, the injection holes of the dissolved air water are processed at fixed intervals, and the diameter of the injection holes can be adjusted .

[0026] On the blade surface of the propeller 6 at the bottom of the air flotation cleaning tank 4, a flipping blade 7 is made. When the air flotation cleaning tank is working, the air flotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com