Method for preparing aligned carbon nanotube on surface of polymeric membrane

A polymer film, carbon nanotube technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem that carbon nanotubes are difficult to use directly, the carbon nanotube array is hard, and the preparation cost is high. problem, to achieve the effect of easy large-scale production and application, wide range and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

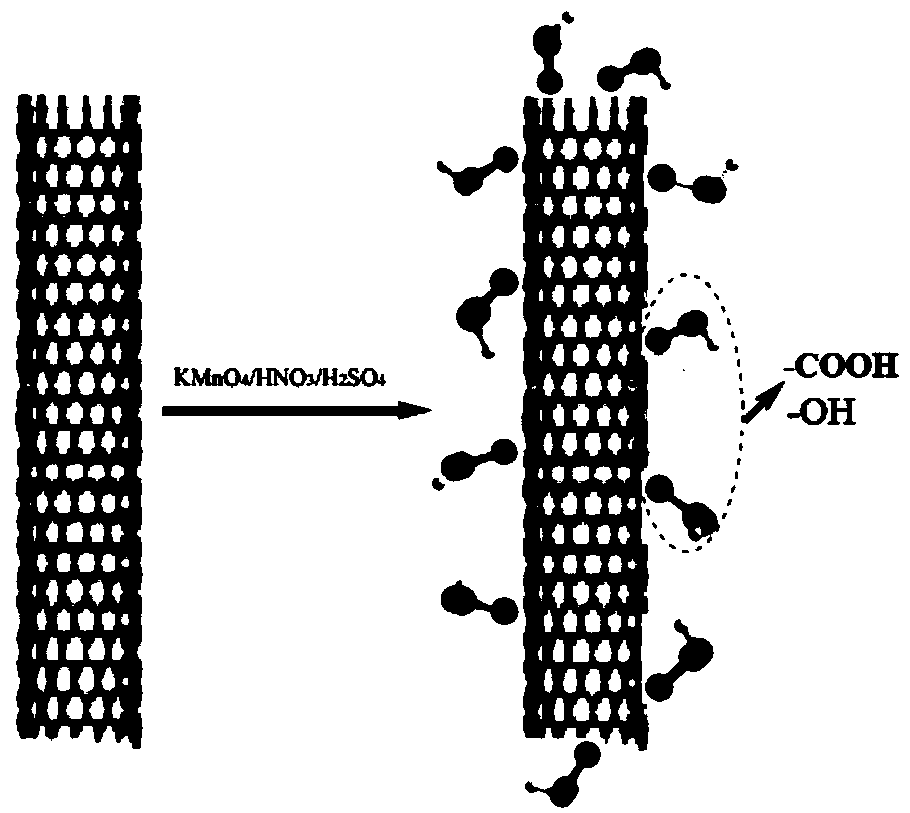

[0041] This embodiment provides a method for preparing acidified modified single-walled carbon nanotubes on the surface of a polysulfone membrane. The specific steps are as follows:

[0042] (1) Add 2g of single-walled carbon nanotubes (Shenzhen Nanoport Co., Ltd., 1-3nm in diameter and 1-5μm in length) to 100ml of concentrated sulfuric acid / concentrated nitric acid mixed acid (concentrated H 2 SO 4 : concentrated HNO 3 Volume ratio = 3:1), modified at 80°C for 12 hours, then filtered, washed, and dried to obtain modified single-walled carbon nanotubes;

[0043] (2) Dispersing 0.02g modified single-walled carbon nanotubes in water, and obtaining a uniformly dispersed modified single-walled carbon nanotube dispersion with a concentration of 0.1g / L after ultrasonic treatment;

[0044] (3) The modified single-walled carbon nanotube dispersion is evenly deposited on the surface of the polysulfone polymer membrane (Hangzhou Water Treatment Technology Research and Development Cent...

Embodiment 2

[0048] The implementation is the same as in Example 1, only the single-walled carbon nanotubes in the raw material are replaced with multi-walled carbon nanotubes (Shenzhen Nanoport Co., Ltd., diameter 1-7nm, length 1-5μm), and the obtained aligned carbon nanotubes The tube was similar to that in Example 1.

Embodiment 3~6

[0050] The implementation is the same as in Example 1, except that sulfuric acid, nitric acid, potassium permanganate or a mixture of the three (mass ratio 5:2:1) is used as the oxidizing agent to change the oxidation treatment, and the obtained aligned carbon nanotubes are the same as those in Example 1. similar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com