800mpa grade high-strength steel with low composition and low pcm value and its production method

A production method and high-strength steel technology, applied in the field of high-strength structural steel, can solve problems such as difficulty in ensuring the internal quality of steel billets or steel plates, low final cooling temperature, and increased smelting difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

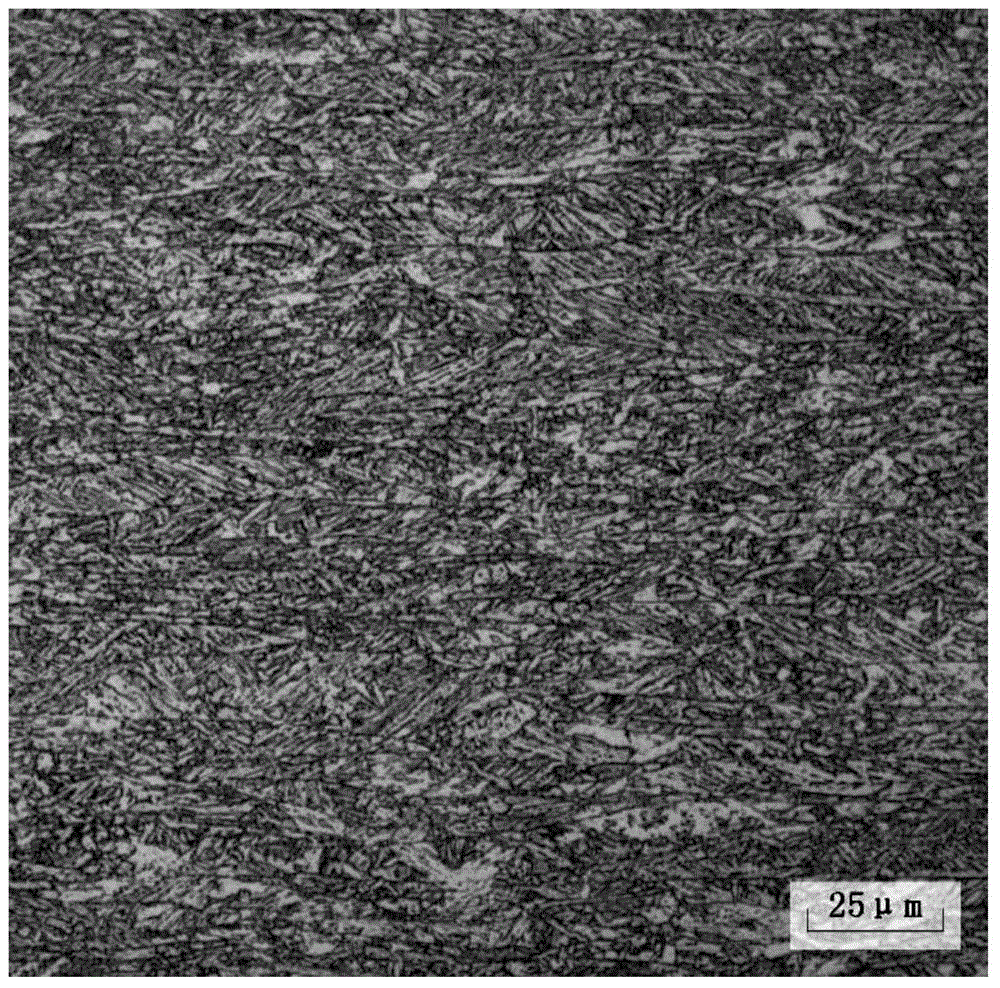

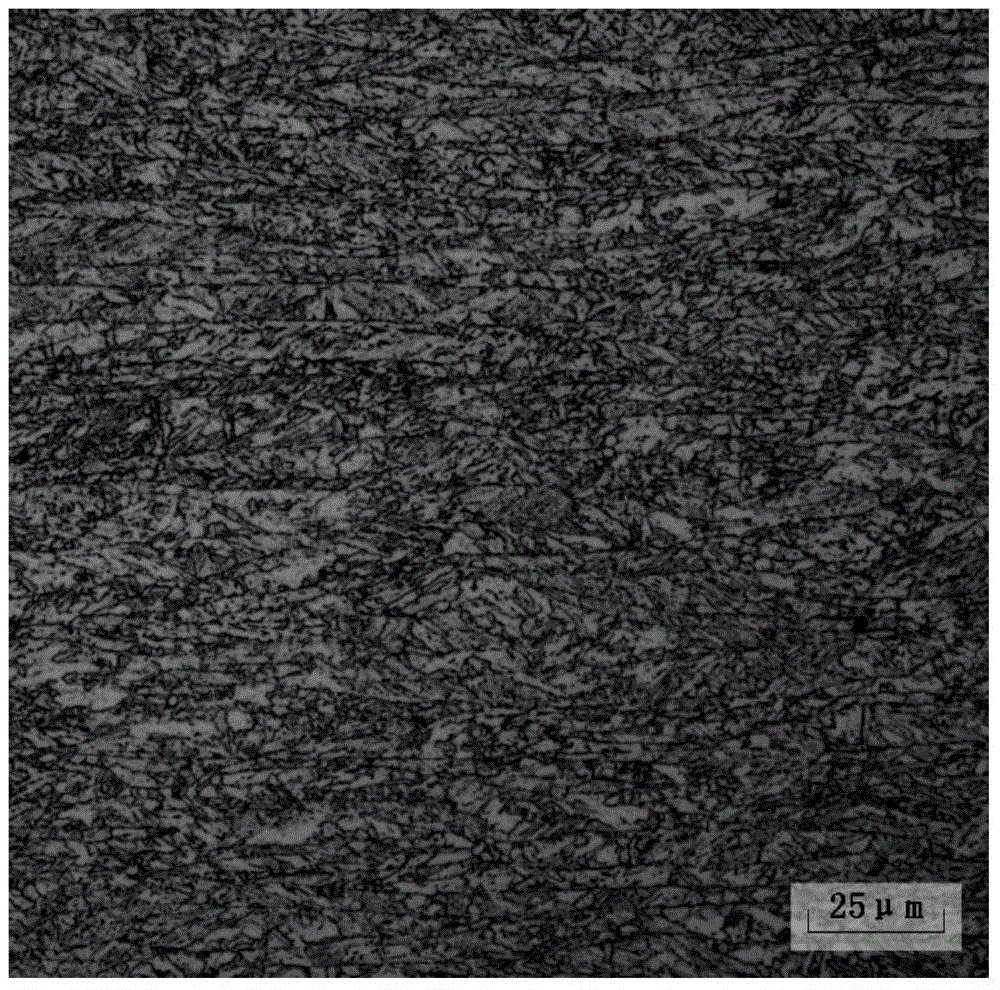

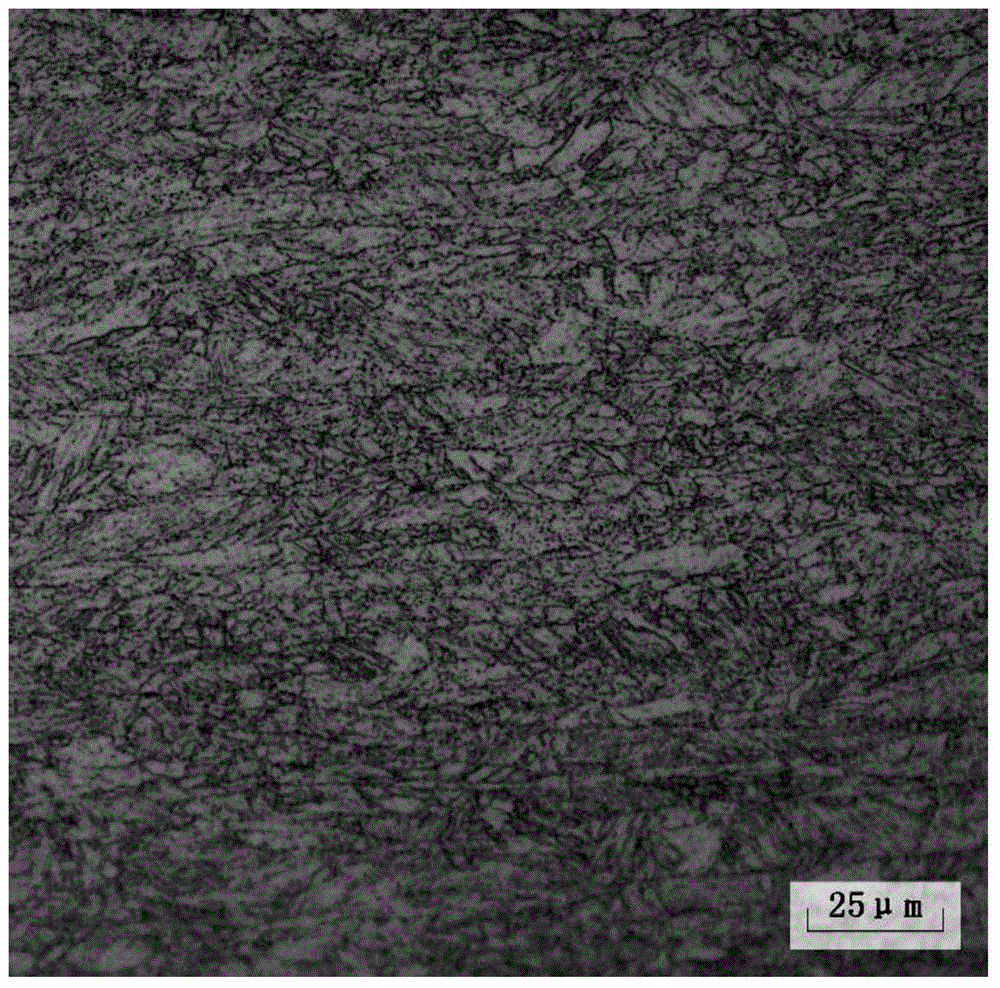

[0023] According to the chemical composition range requirements of the present invention "a high-strength steel with low composition and low Pcm value tensile strength 800MPa grade", slab smelting, slab casting and steel plate rolling (thickness specification) were completed in Shouqin Company's "4300mm wide and thick plate production line". -20mm, 30mm) and tempering treatment.

[0024] The actual chemical composition of the 800MPa high-strength steel in this example is shown in Table 3:

[0025] Table 3 chemical composition (wt%)

[0026] Numbering

C

Si

mn

Cr

P

S

Alt

V

Nb

Ti

B

Pcm

1#

0.070

0.20

1.71

O.12

0.010

0.005

0.028

0.078

0.042

0.014

0.0015

0.18

2#

0.085

0.25

1.79

0.19

0.009

0.004

0.025

0.070

0.050

0.015

0.0017

0.21

[0027]The rolling process parameter setting of this example is shown in Table 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com