Preparation method of water repellent finishing agent

A technology of water-repellent finishing and ammonia water, which is applied in the fields of fiber treatment, textiles and papermaking, and can solve the problems of human poisoning, high cost of fluorine-containing treatment liquid, and non-pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 8 mL of 26% ammonia water to 90 g of ethanol. After stirring for ten minutes, add 7 mL of analytically pure ethyl orthosilicate at a time for 3 hours to prepare a blue transparent nano silica sol. Adjust the pH of the nano silica sol to 6 with citric acid.

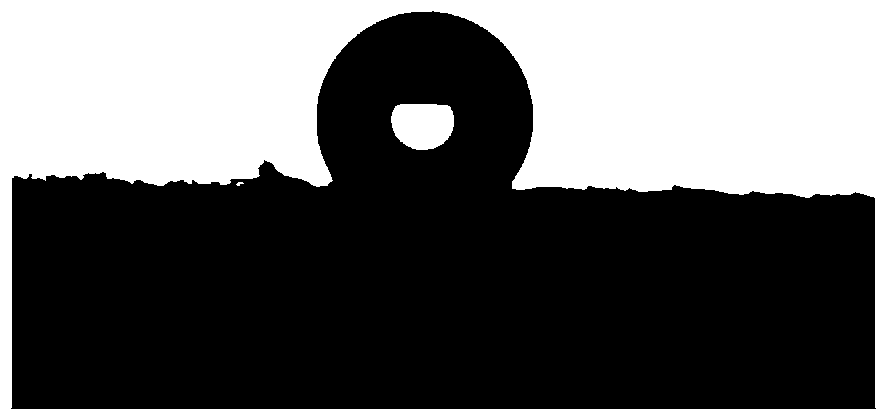

[0018] The above-mentioned nano-silica sol and fluorine-containing polyacrylate are compounded according to a mass ratio of 1:80. Finish the 30g / L compound finishing agent on the cotton fabric, and the liquid rate of the cotton fabric is 65%. The process of fabric finishing is: padding (two soaking and two rolling)→drying (100℃×2min)→baking (150℃×3min). The measured contact angle of the finished fabric is 143.35°, such as figure 2 Shown. Compared with the comparative example, under the condition that the various parameters of the experiment are the same, the water repellency of the fabric finished with the nano silica sol is improved, and at the same time, the amount of fluorinated polyacrylate is reduced. .

Embodiment 2

[0020] Add 10 mL of 27% ammonia water to 100 g of ethanol, stir for ten minutes, add 8 mL of analytically pure ethyl orthosilicate at a time, and react for 4 hours to prepare a blue transparent nano silica sol. Adjust the pH of the nano silica sol to 5 with citric acid.

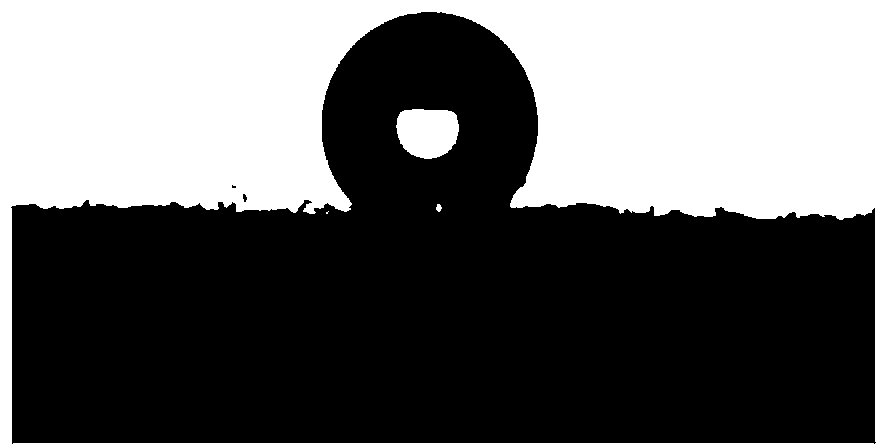

[0021] The above-mentioned nano-silica sol and fluorine-containing polyacrylate are compounded according to a mass ratio of 1:40. Finish the compound finishing agent on the cotton fabric, the liquid rate of the cotton fabric is 65%. The process of fabric finishing is: padding (two soaking and two rolling)→drying (100℃×2min)→baking (150℃×3min). The measured contact angle of the finished fabric is 150.77°, such as image 3 Shown.

Embodiment 3

[0023] 12 mL of 28% ammonia water was added to 110 g of ethanol, and after stirring for ten minutes, 9 mL of analytically pure ethyl orthosilicate was added at one time to react for 5 hours to prepare a blue transparent nano silica sol. Adjust the pH of the nano silica sol to 6 with citric acid.

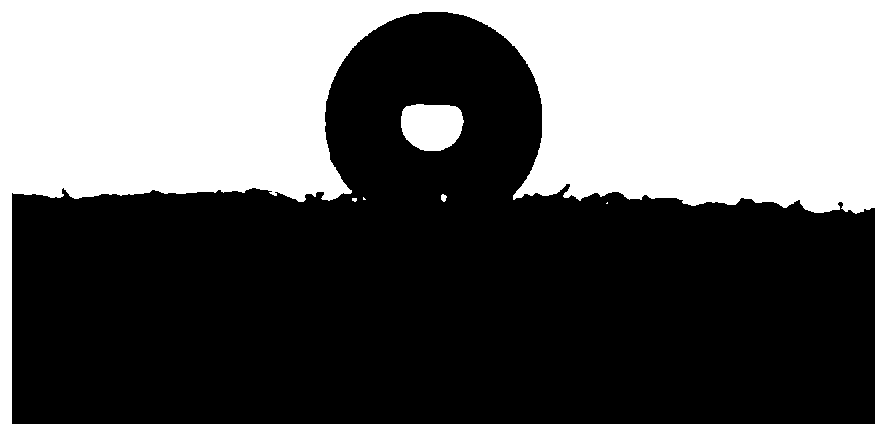

[0024] The above-mentioned nano-silica sol and fluorine-containing polyacrylate are compounded according to a mass ratio of 3:80. After finishing the compound finishing agent on the fabric, the liquid-carrying rate of the cotton fabric is 65%. The process of fabric finishing is: padding (two soaking and two rolling)→drying (100℃×2min)→baking (150℃×3min). The measured contact angle of the finished fabric is 150.64°, such as Figure 4 Shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com