Supporting device for tire of rotary body

A supporting device and rotator technology, applied in transmission devices, drum furnaces, dry solid materials, etc., can solve problems such as inappropriate tire gaps, contact surface wear, cylinder deformation, etc., to save maintenance costs and improve use Life, the effect of preventing axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

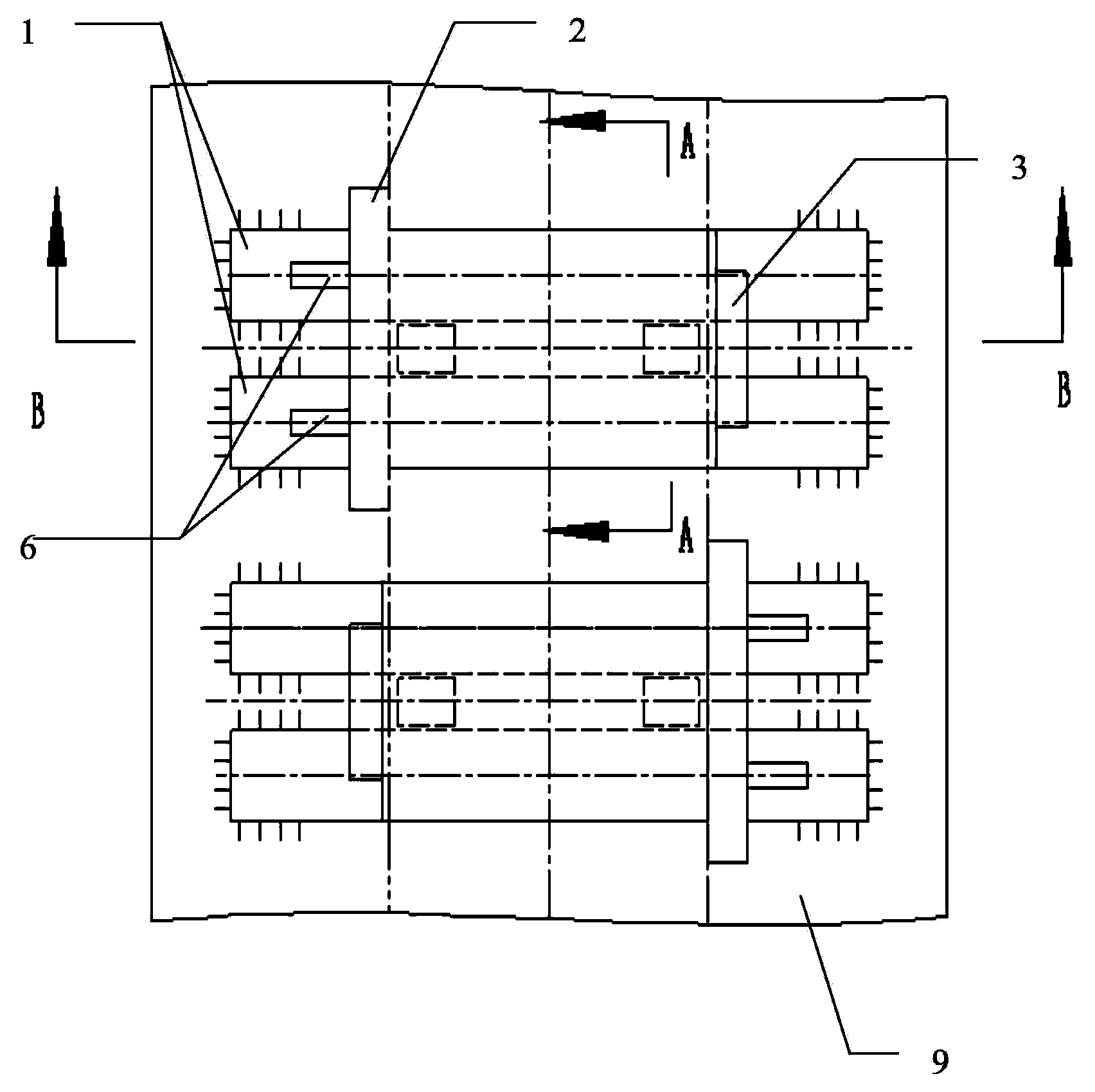

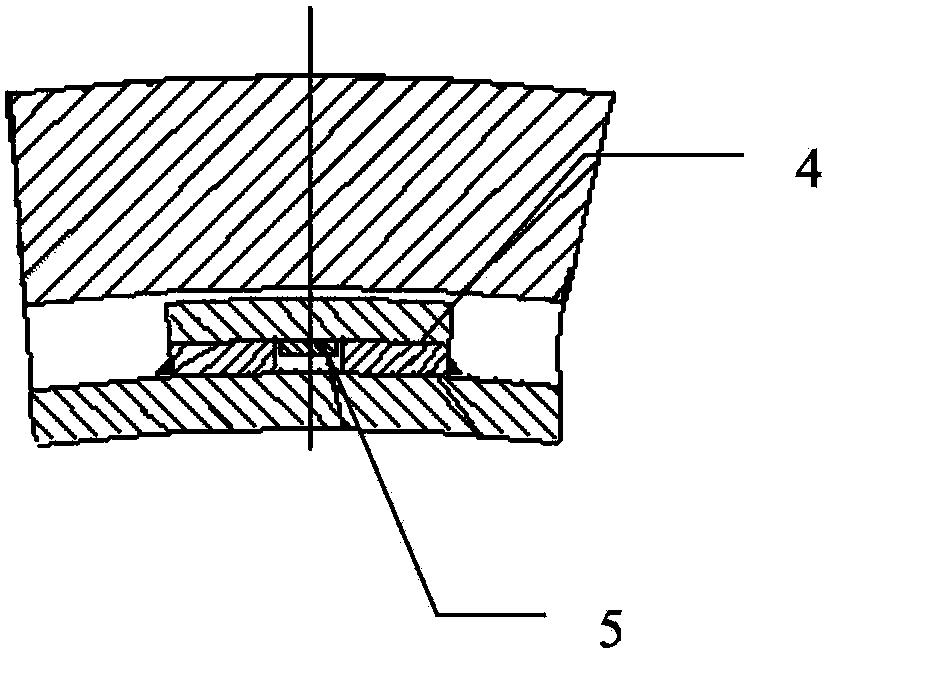

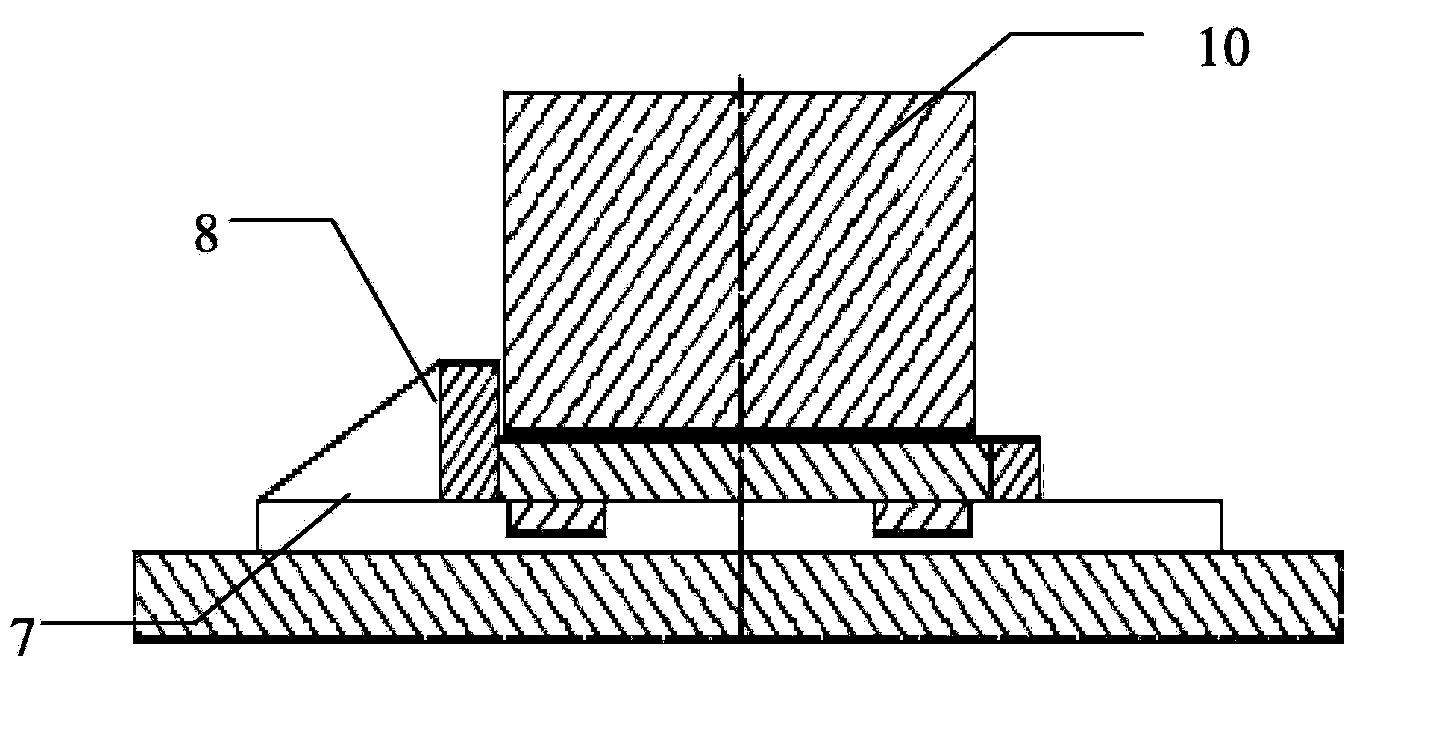

[0025] Such as Figure 1~4 As shown, a supporting device for a revolving wheel belt includes: a pair of first plates 1 , clamping parts, long fixing parts 2 and short fixing parts 3 , a fixing frame 11 , a cooling fan 12 and a control device 13 . A pair of first plate bodies 1 are fixed on the outer periphery of the rotary body 9 parallel to each other, and there is a first gap between the pair of first plate bodies 1 fixed on the outer periphery of the rotary body 9; the clamping part includes a second plate Body 4 and a pair of clamping blocks 5, a pair of clamping blocks 5 are fixed on the second plate body 4, the second plate body 4 is overlapped on a pair of first plate bodies 1, and a pair of clamping blocks 5 are clamped into the first gap ; fixed frame 11, which is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com