High pressure gas vortex expanded carbon dioxide low temperature refrigerating system

A low-temperature refrigeration system and high-pressure gas technology, used in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of low system performance coefficient, large throttling process loss of throttling and pressure-reducing components, and achieve no moving parts, Easy maintenance and lightweight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

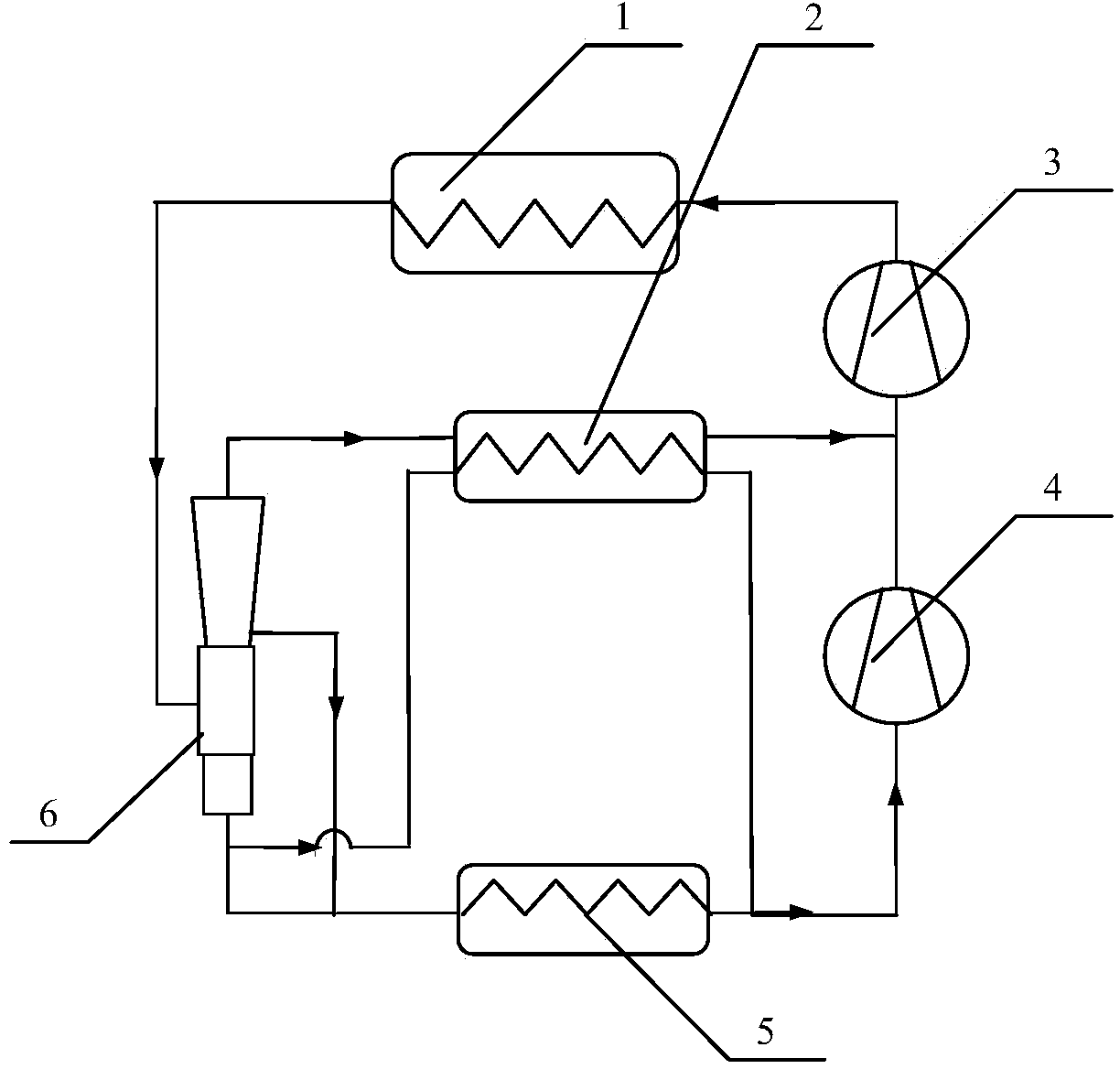

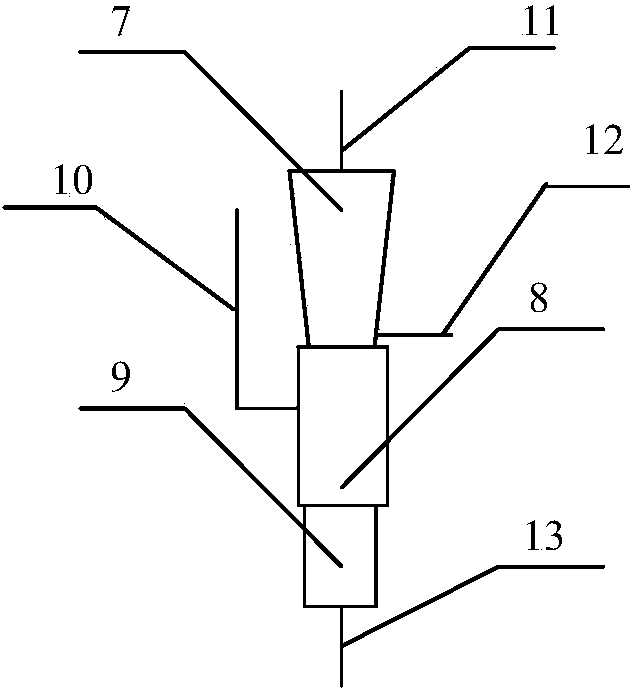

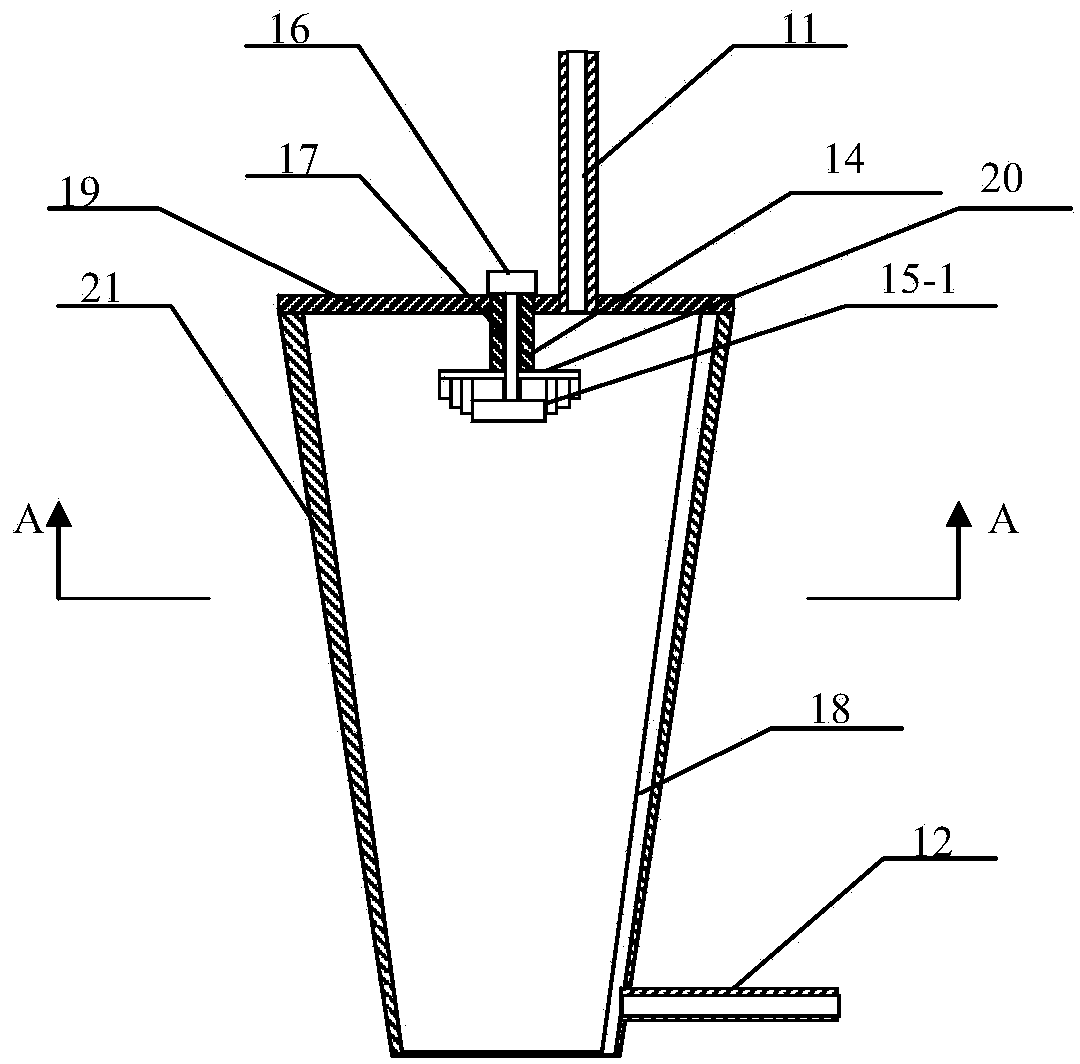

[0022] The schematic diagram of the low-temperature refrigeration system of the high-pressure gas vortex expansion of the present invention is as follows Figure 1-Figure 4 As shown, a gas cooler 1 , a heat exchanger 2 , a high pressure stage compressor 3 , a low pressure stage compressor 4 , an evaporator 5 and a vortex tube 6 are included. The vortex tube of the present invention is an improvement on the prior art, and the original hot section is improved into a hot diffuser section with a diffusion effect. Specifically: the vortex tube 6 includes a vortex chamber 8, a cold section 9 and a hot diffuser section 7, the hot diffuser section 7 includes a diffuser body 21 communicated with the vortex chamber 8, and the diffuser body 21 A saturated liquid collection groove 18 is provided on the inner wall of the saturated liquid collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com