Bonding tool detection method

A detection method and technology of bonding tools, which are applied in the direction of manufacturing tools, measuring devices, metal processing equipment, etc., can solve problems such as unqualified detection of bonding tools, failure to judge MEMS devices, etc., and achieve the effect of avoiding product waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

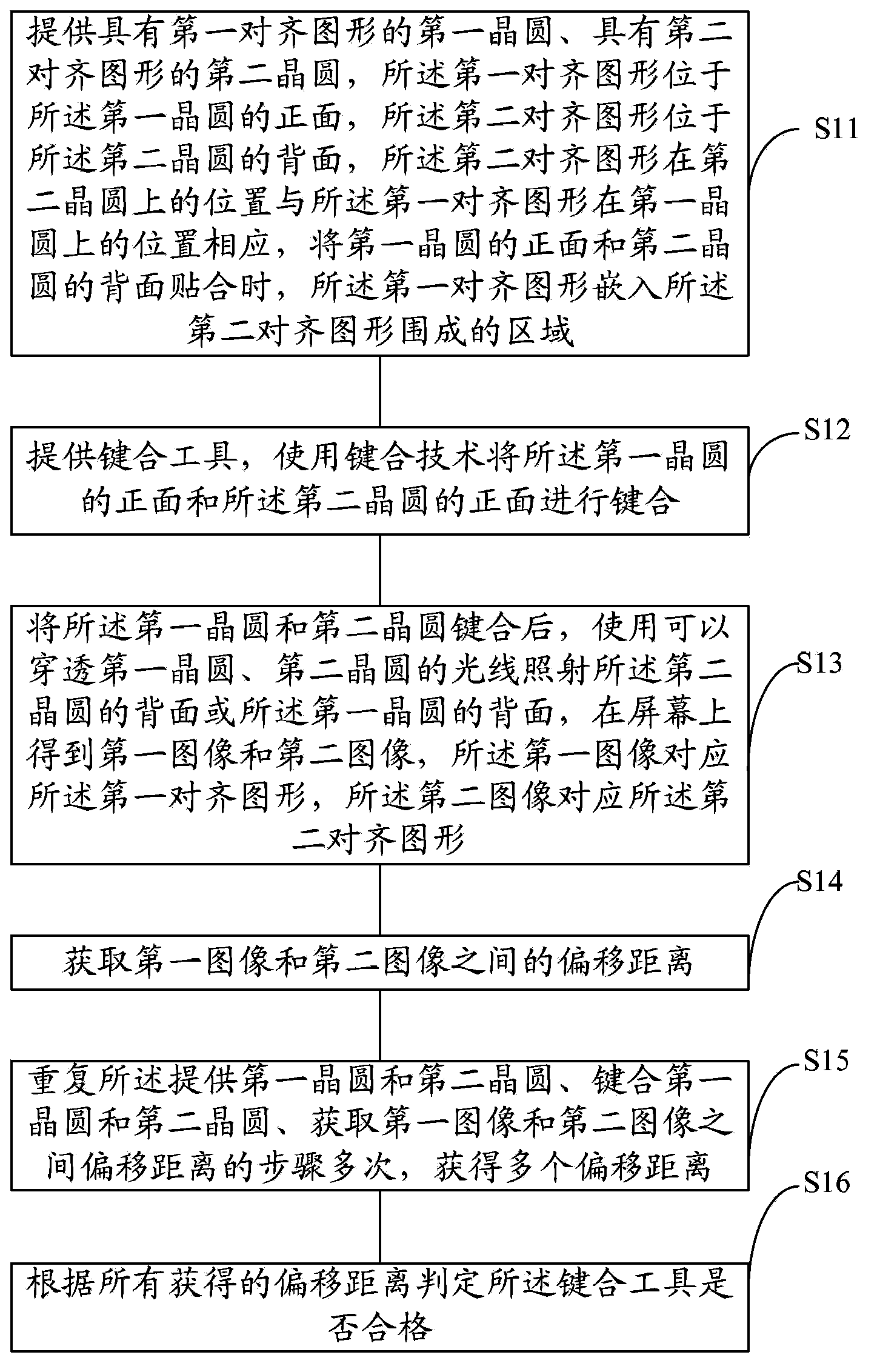

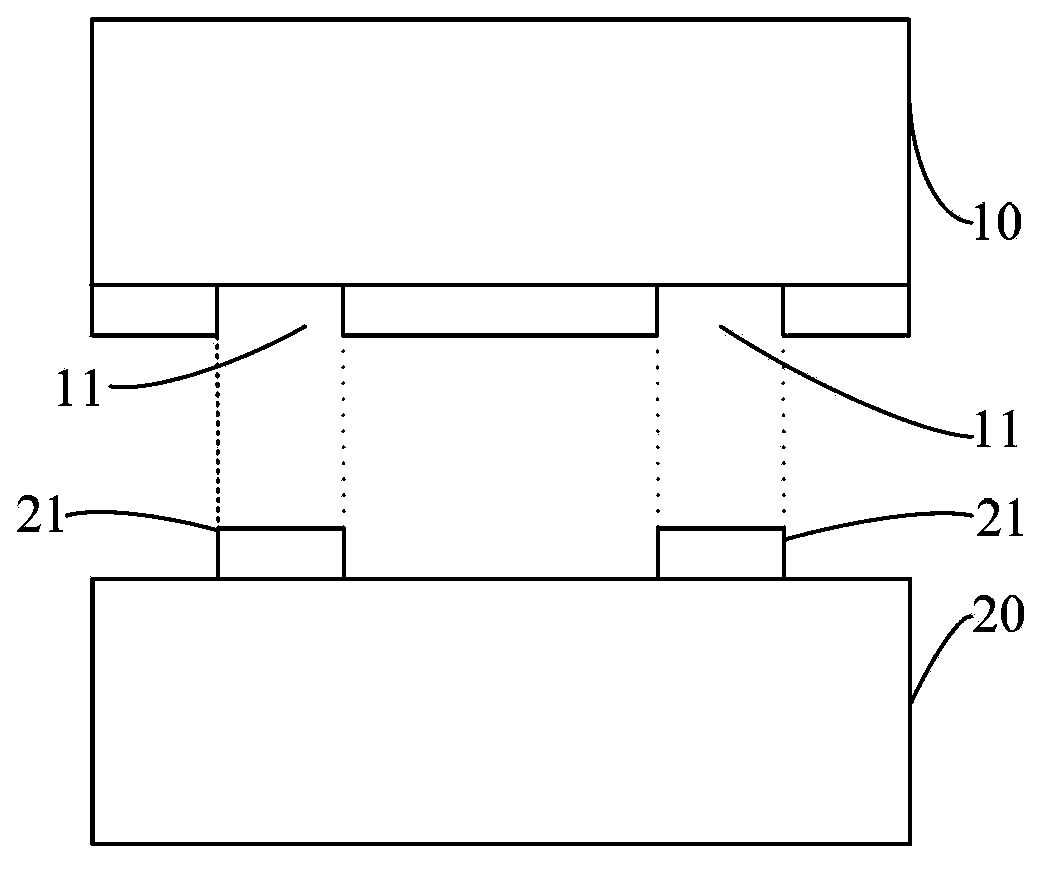

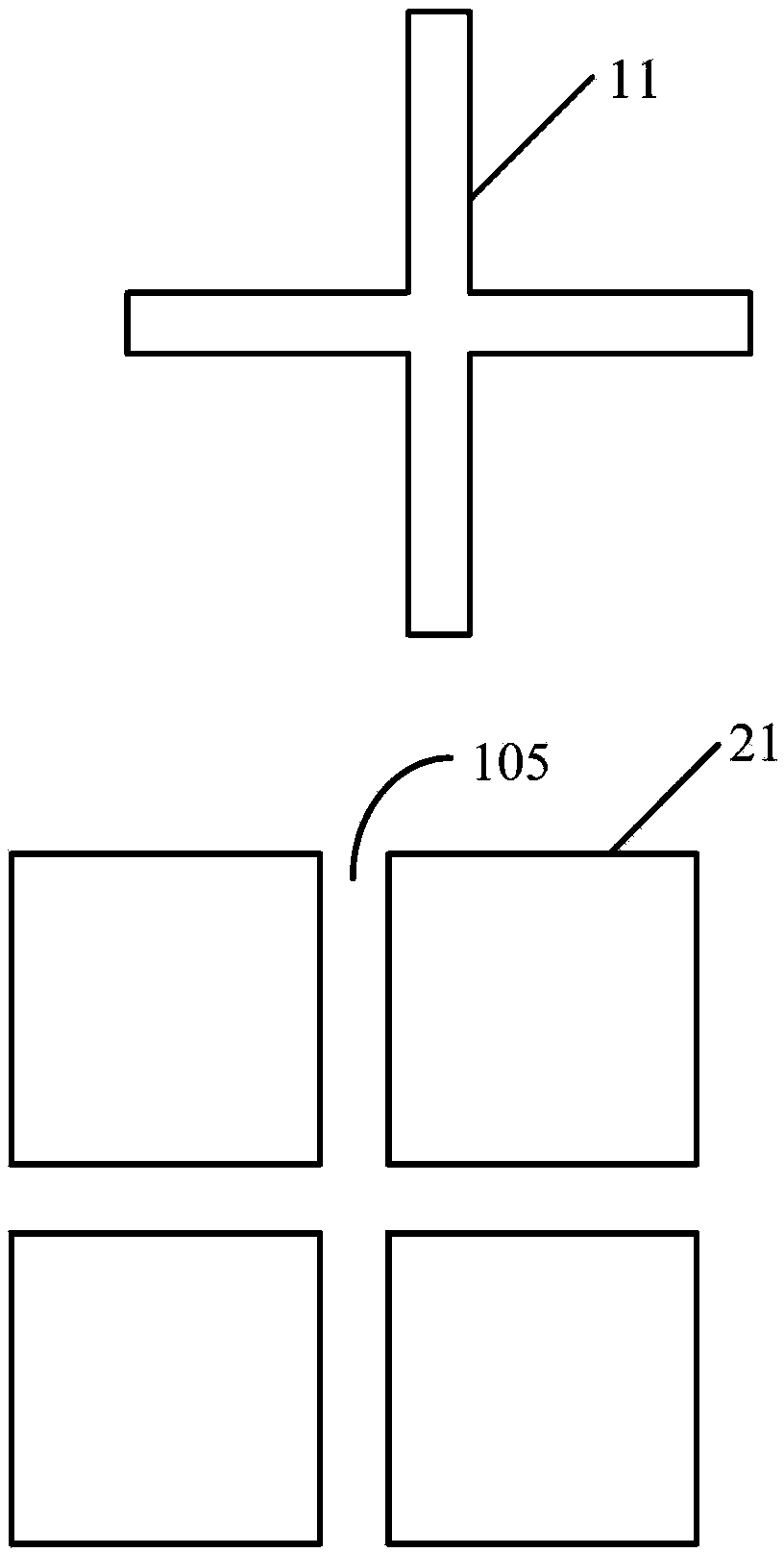

[0040]The inventors conducted research on defective MEMS device products obtained by using bonding tools in metal bonding technology, and found that: during the metal bonding process, when using bonding tools to press metal and wafer or metal and metal , it will cause the bonding contact points between metal and metal, or metal and wafer are not completely aligned, that is, the metal is offset relative to the wafer or one of the metals relative to the other metal during the bonding process, so that The resulting product will not function properly due to poor contact at the bonding contacts. Furthermore, the bonded contacts are prone to breakage, rendering the product inoperable. The inventor has noticed that the reason for the bonding offset is mainly that there is a problem with the bonding tool itself, such as in the bonding tool, the contact between metal and metal or metal and wafer is closer and firm. Or the size and direction of the pressure exerted by the metal are une...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com