Parameter detection method and monitoring device for mine filling slurry

A detection method and slurry technology, which is applied in the direction of measuring devices, analyzing materials, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as inability to apply, inability to realize online monitoring, radiation pollution, etc., and achieve the effect of small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the drawings and embodiments:

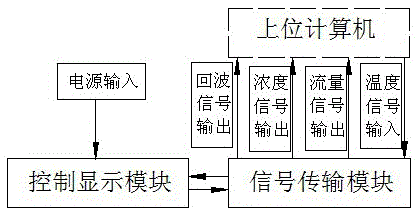

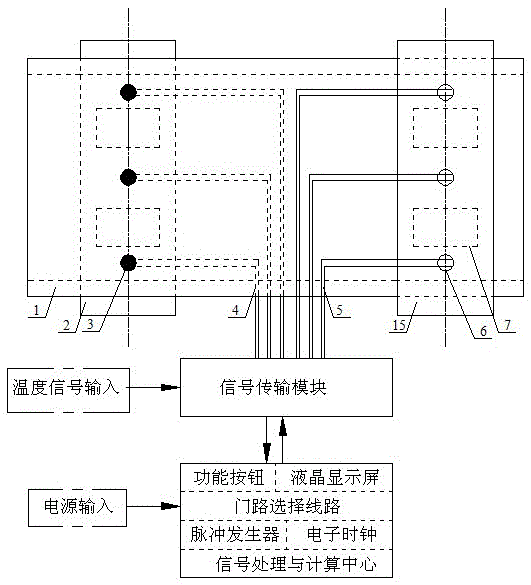

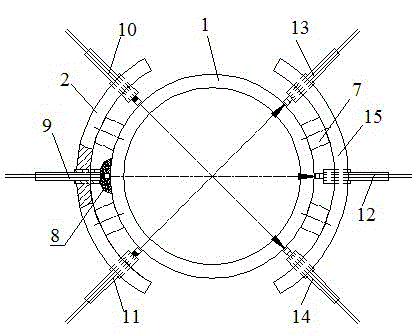

[0035] Attached Figure 1 to 4 It can be seen that a mine filling slurry parameter monitoring device includes an arc-shaped launch base 2 and an arc-shaped receiving base 15 arranged on the outside of the slurry pipeline 1; the launch base 2 is provided with an ultrasonic transmitting transducer 3; the receiving base 15 is provided There is an ultrasonic receiving transducer 6; the transmitter base 2 and the receiver base 15 are offset along the axis of the slurry pipeline 1; the temperature sensor is installed by contact punching, and the temperature sensor is set on the outside of the transmitter base 2 and the receiver base 15 10-15 Centimeters; the ultrasonic transmitting transducer 3, the ultrasonic receiving transducer 6 and the temperature sensor are connected with the signal processing computing center and the control display module through the signal transmiss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com