A kind of antifreeze high-strength supramolecular organic hydrogel and preparation method thereof

A hydrogel, high-strength technology, applied in the field of functional materials, can solve the problems of insufficient mechanical properties of antifreeze organic hydrogels, cumbersome preparation process, complex composition of raw materials, etc., to achieve good antifreeze characteristics, single gel composition, Source-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Preparation of high-strength supramolecular gelatin organohydrogel with antifreeze properties

[0031] (1) Prepare an aqueous gelatin solution with a concentration of 0.1 g / ml, heat to 60° C., and stir for 35 minutes to obtain a transparent aqueous gelatin solution.

[0032] (2) Transfer the obtained gelatin solution into a cuboid mold, and then place it at 4° C. for 30 min to obtain a gelatin pre-hydrogel.

[0033] (3) prepare water / glycerol mixed solution, wherein the massfraction that glycerin accounts for mixed solution is 50wt%; Take a certain amount of sodium citrate (Na 3 Cit), it is dissolved therein, makes its mass fraction be 20wt%, forms Na 3 Cit's water / glycerol solution, set aside.

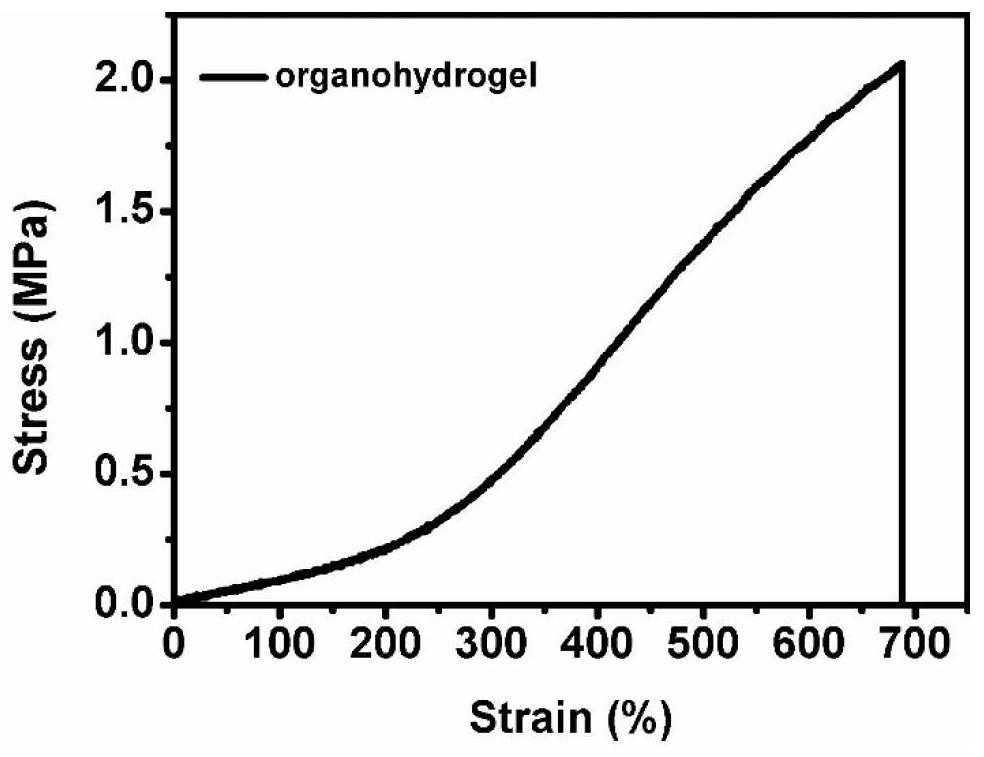

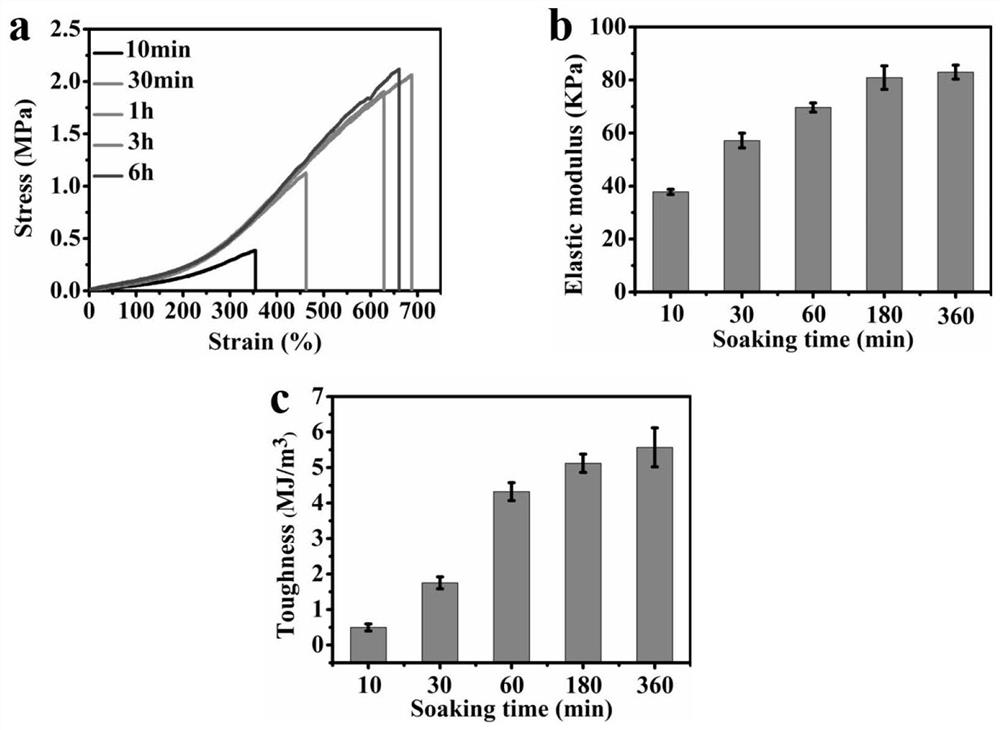

[0034] (4) Soak the gelatin pre-hydrogel in the Na obtained in step (3) 3 In the water / glycerol solution of Cit, soak for 3 hours, so that the water molecules in the gelatin pregel are partially replaced by glycerol, and the gelatin molecular chains generate hydro...

Embodiment 2

[0038] (1) Prepare an aqueous gelatin solution with a concentration of 0.02 g / ml, heat to 50° C., and stir for 10 minutes to obtain a transparent aqueous gelatin solution.

[0039] (2) Transfer the obtained gelatin solution into a cuboid mold, and then place it at 4° C. for 50 min to obtain a gelatin pre-hydrogel.

[0040] (3) prepare water / glycerol mixed solution, wherein the massfraction that glycerin accounts for mixed solution is 1wt%; Take a certain amount of sodium citrate (Na 3 Cit), it is dissolved therein, makes its mass fraction be 1wt%, forms Na 3 Cit's water / glycerol solution, set aside.

[0041] (4) Soak the gained gelatin pre-hydrogel in the Na obtained in step (3) 3In the water / glycerol solution of Cit, soak for 15 minutes, finally obtain supramolecular gelatin organohydrogel.

Embodiment 3

[0043] (1) Prepare an aqueous gelatin solution with a concentration of 0.02 g / ml, heat to 50° C., and stir for 10 minutes to obtain a transparent aqueous gelatin solution.

[0044] (2) Transfer the obtained gelatin solution into a cuboid mold, and then place it at 4° C. for 50 min to obtain a gelatin pre-hydrogel.

[0045] (3) prepare water / glycerin mixed solution, wherein the massfraction that glycerin accounts for mixed solution is 99wt%; Take a certain amount of sodium citrate (Na 3 Cit), it is dissolved therein, makes its mass fraction be 40wt%, forms Na 3 Cit's water / glycerol solution, set aside.

[0046] (4) Soak the gained gelatin pre-hydrogel in the Na obtained in step (3) 3 In the water / glycerin solution of Cit, immerse for 12 hours, finally obtain supramolecular gelatin organohydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Fracture strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com