System and method for forward-direction cross-hole radar transmission imaging advanced prediction of TBM construction tunnel

A technology of advanced forecasting and radar, which is applied in geophysical measurement and instruments, can solve the problems of long test time, influence on construction progress, small detection distance, etc., and achieve the effects of saving detection time, improving efficiency, and enhancing radar signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

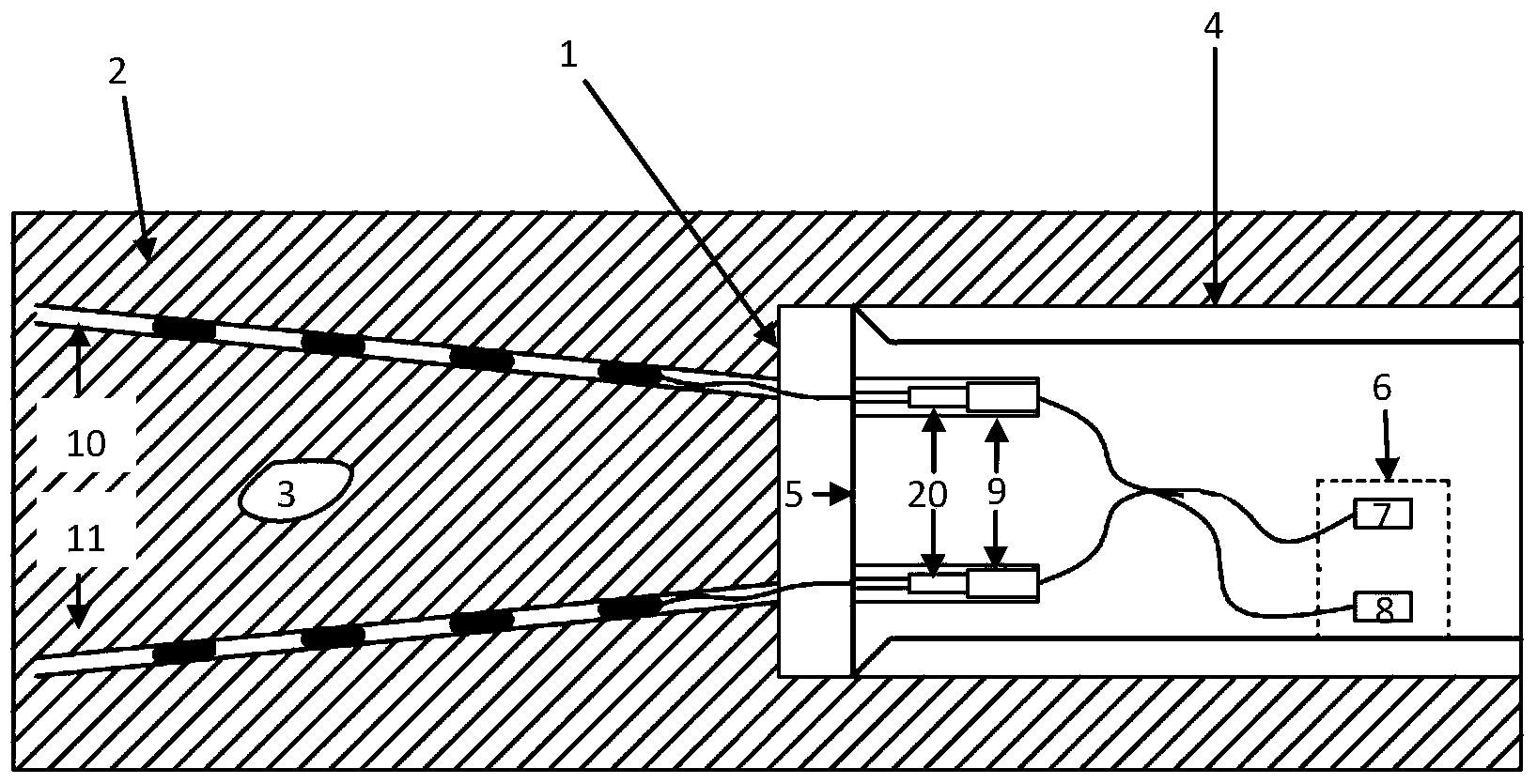

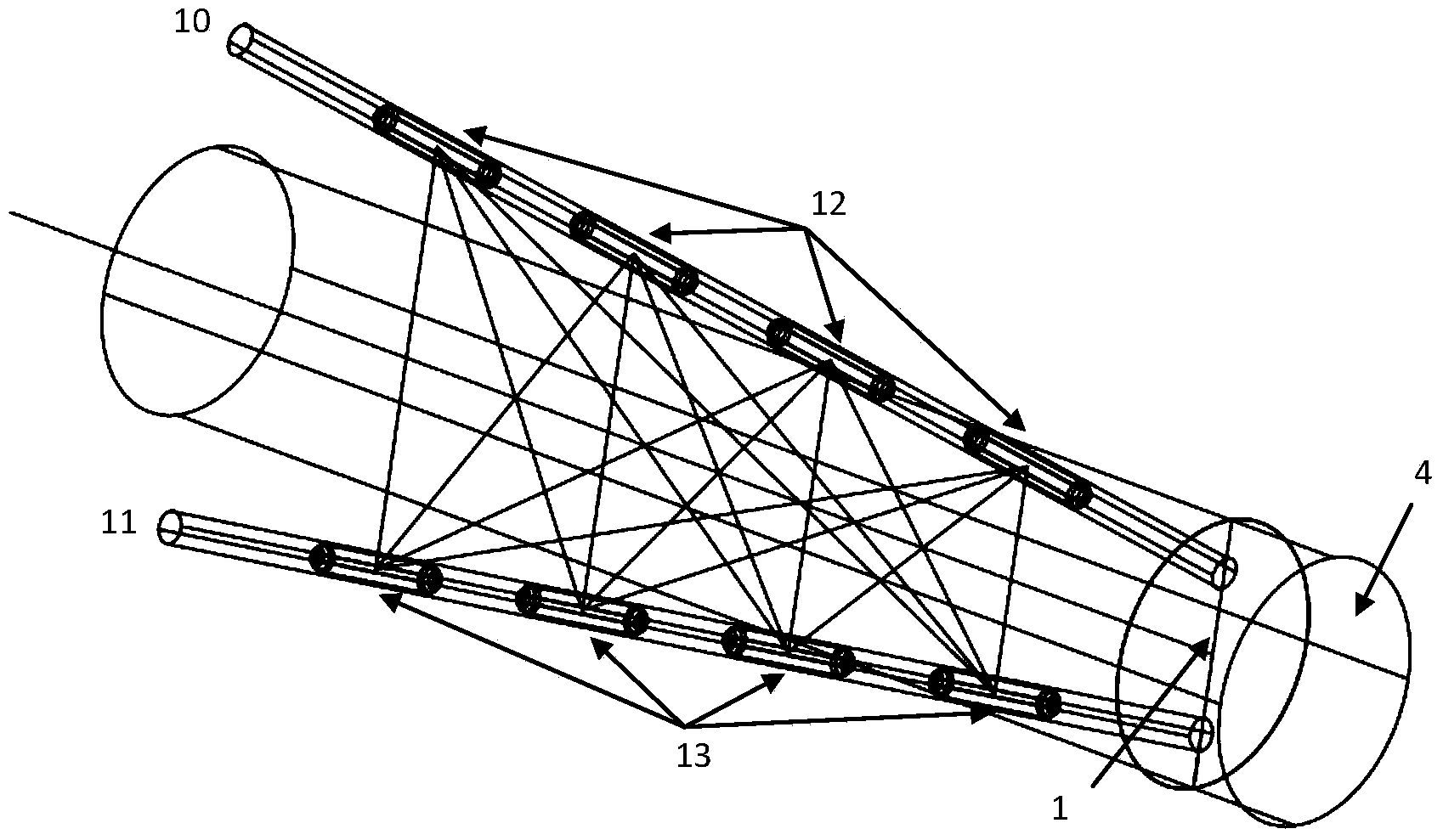

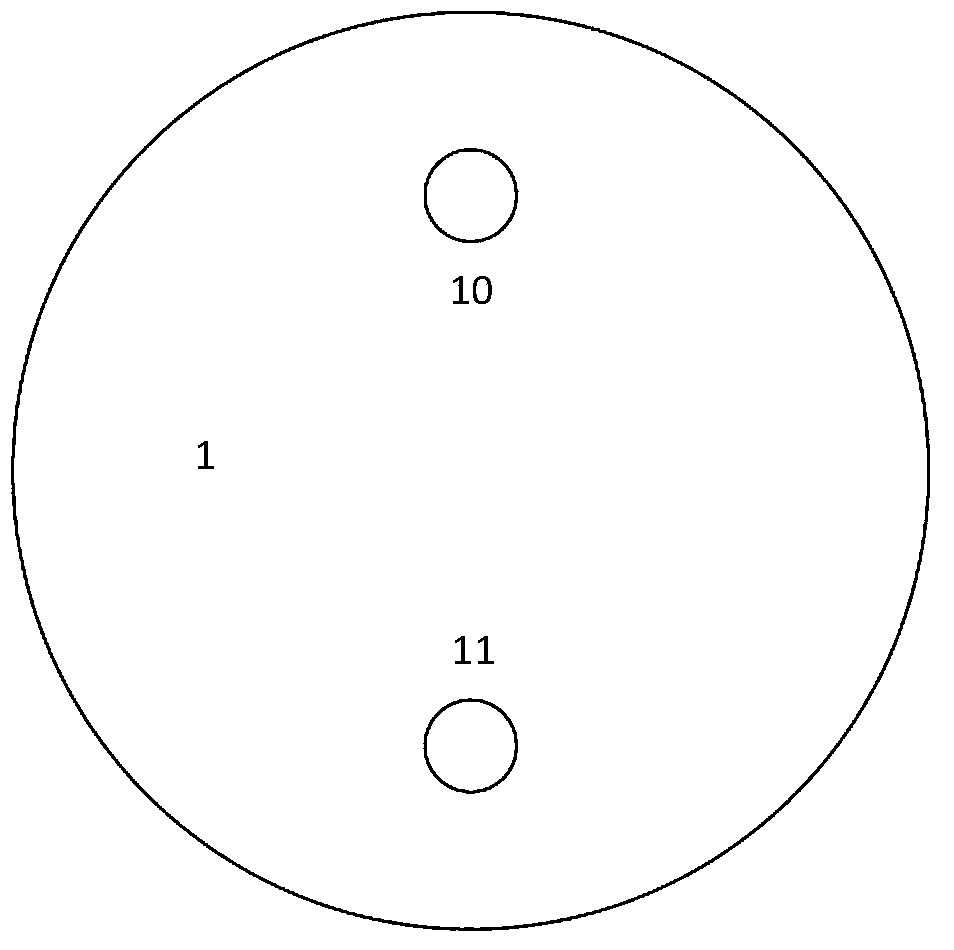

[0052] Such as figure 1 , figure 2 As shown, a TBM construction tunnel forward cross-hole radar transmission imaging rapid advance forecast system, which includes: multi-channel radar host and computer 7, mechanical telescopic precession device controller 8, drilling rig and radar antenna cabin 9, upper drilling 10. Borehole 11, radar receiving antenna 12, radar transmitting antenna 13, etc., and mechanical telescopic screw-in device 17 are located in drilling rig and radar antenna cabin 9.

[0053] The TBM mechanical main body 4 is located behind the tunnel excavation face 1, the multi-channel radar host computer 7 and the mechanical telescopic screwing device controller 8 are installed in the main control room 6, and the main control room 6 is located in the TBM mechanical main body 4. 5. Carry out forward excavation. When the excavation reaches th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com