Non-symmetric flex-rigid combination circuit board and manufacturing method thereof

A rigid-flex bonding, circuit board technology, applied in the direction of multi-layer circuit manufacturing, printed circuit components, etc., can solve the problems of insufficient glue flow on the board surface, unable to make edge lines, and thin plate ink accumulation. Flexible design of number and thickness, satisfying the effect of one-time filming and improving the flatness of the board surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The application will be further elaborated below in conjunction with the accompanying drawings and embodiments.

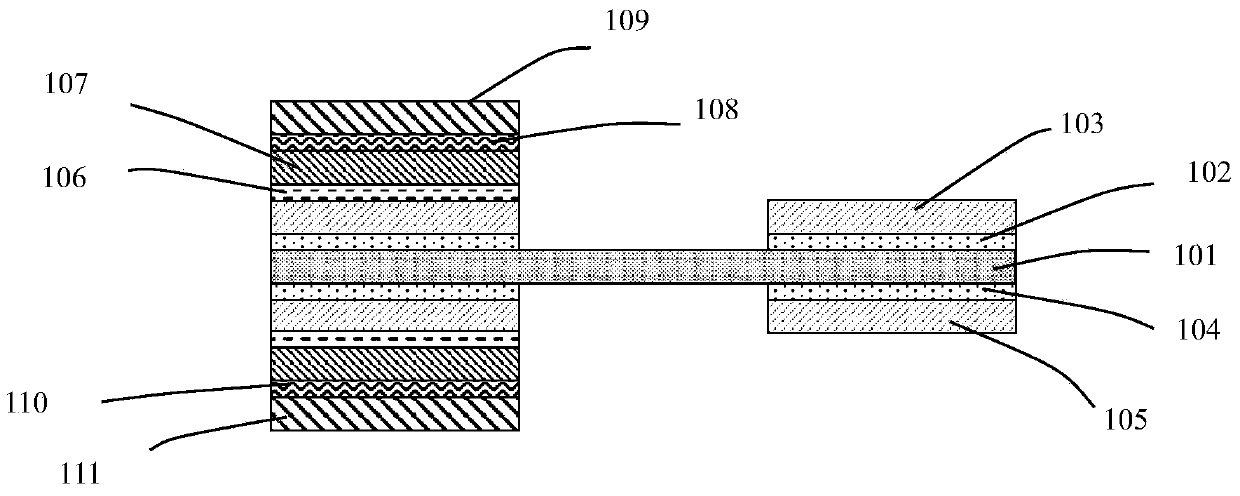

[0052] refer to figure 1 , an asymmetric rigid-flex circuit board, which includes a flexible sub-board 101, a first dielectric layer 102, a first rigid sub-board 103, a second dielectric layer 106 and a second rigid sub-board stacked in sequence plate 107;

[0053] The flexible sub-board is provided with a thick rigid area, a flexible area and a thin rigid area, and the thick rigid area and the thin rigid area are connected through a flexible area;

[0054] The first dielectric layer and the first rigid sub-plate are respectively provided with a first window area and a second window area corresponding to the flexible area;

[0055] The second dielectric layer is provided with a third window area corresponding to the flexible area and the thin rigid area, and the second rigid sub-plate is provided with a fourth window area corresponding to the third window ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com