Method for picking Chinese wolfberries by high-speed air flow and Chinese wolfberry picking device

A technology of high-speed airflow and airflow direction, which is applied in the direction of picking machines, applications, agricultural machinery and implements, etc., can solve the problems of reducing the cost of wolfberry picking and failing to greatly improve the efficiency of wolfberry picking, so as to reduce labor intensity, and the method is simple and effective. The effect of high picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

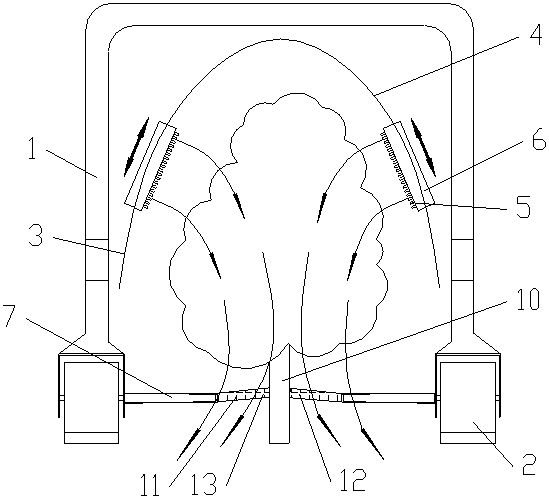

[0026] see figure 1In the wolfberry picking device shown, two groups of rollers (traveling mechanism) 2 are respectively arranged on both sides of the lower part of the frame 1, and the air compressor and the traveling driving device for driving the rollers to rotate are respectively arranged on both sides of the frame. Two slide bars 3, 4 are arranged on the frame, and the upper ends of the two slide bars are connected, and the two slide bars form a parabola with an opening downward. A plurality of nozzles 5 are arranged on the nozzle base 6, and each nozzle communicates with the air channel on the nozzle base, and the air channels on the two nozzle bases respectively communicate with the air outlet of the air compressor through the discharge pipeline. Solenoid valves are respectively arranged on the two discharge pipelines. The nozzle seat can slide along the slide bar, and at the same time, the nozzle can swing relative to the nozzle seat. The nozzle seat is provided with...

Embodiment 2

[0031] The distance between nozzles blowing air alternately from both sides to the wolfberry branches is controlled by the solenoid valve, so as to realize the swing of the wolfberry branches relative to each other. In the experiment, when the distance between the nozzle and the wolfberry branches is about 350mm, the speed of the airflow reaching the wolfberry branches is about 14m / s. The frequency of the two solenoid valve switches is 3Hz (the time of the open state and the closed state are equal), and the two spray lines blow air alternately. According to the calculation formula of embodiment 1, the force acting on the mature wolfberry is 1.57 × 10 -2 N, equivalent to the gravity of a weight of 1.6g, plus the self-weight of wolfberry exceeds 0.6g, so it can meet the conditions of overcoming the binding force (2g) of the fruit stalk of mature wolfberry, and the fruit of wolfberry can fall off from the branches. In addition, the high-speed airflow is switched on and off throu...

Embodiment 3

[0033] see image 3 , 4 In the wolfberry picking device shown, the nozzle frame 23 includes two lifting plates 231, 232 on the left and right; two left sliding bars 241 and a left sliding table guide rod 251 are fixed on the left lifting plate; A right slide bar 242 and a right slide table guide bar 252. The two left slide bars 241 and the left slide table guide bar 251 are parallel to each other, and the two right slide bars 242 and the right slide table guide bar 252 are parallel to each other. The upper end of the left sliding bar 241 is inclined to the right, and the upper end of the right sliding bar 242 is inclined to the left. The left and right sliders form the two legs of an isosceles trapezoid.

[0034] The upper ends of the two left slide bars 241 are connected with the left longitudinal bar 261 , and the upper ends of the two right slide bars 242 are connected with the right longitudinal bar 262 . The left slide table 271 is slidably arranged on the left slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com