Method for sorting monohydrallite

A bauxite and pulp technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems such as failure to further increase the mineral processing output, affecting the realization of production capacity, low production capacity of the mill, etc. The effect of increasing production capacity and reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

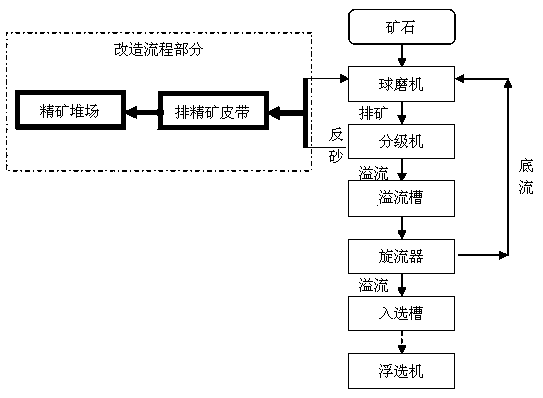

[0015] Grinding and grading diversion system, based on the structure of the original 1# mill and classifier, at the top of the classifier where the sand returns into the chute (at the centerline of internal and external rotation symmetry), a circular hole with a diameter of about 250mm is opened. Below the above-mentioned concentrate discharge port, a chute with a length of about 3m is connected. The upper end of the chute is connected with a flange and is designed with a movable insert plate. If necessary, it can be closed to facilitate maintenance or stop the concentrate discharge process. A belt is connected below the chute, and the concentrate enters the concentrate storage yard.

[0016] After experimentation and exploration, when the 1# mill discharges 80t / h and its discharge of concentrate is about 20t / h, the entire grinding and classification system can maintain stable operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com