A carbon fiber conductive concrete wall type dust removal device

A technology of conductive concrete and dust removal device, applied in the direction of wall, electrostatic separation, external electrostatic separator, etc., can solve the problems of huge equipment, large amount of consumables, complex system, etc., and achieve reasonable structure, low cost and maintenance cost, and dust removal effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings and embodiments.

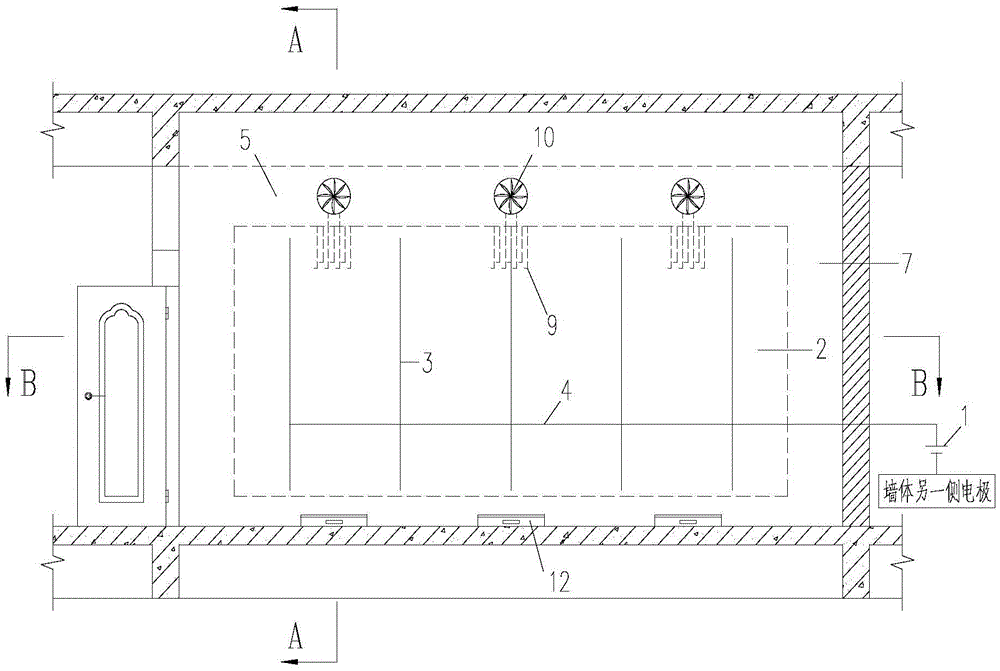

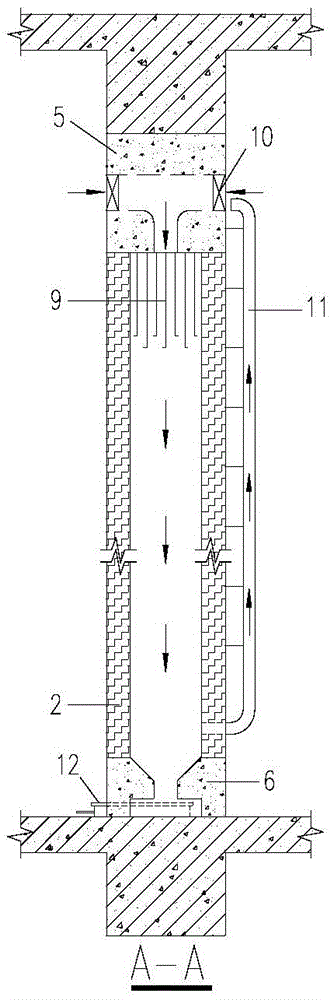

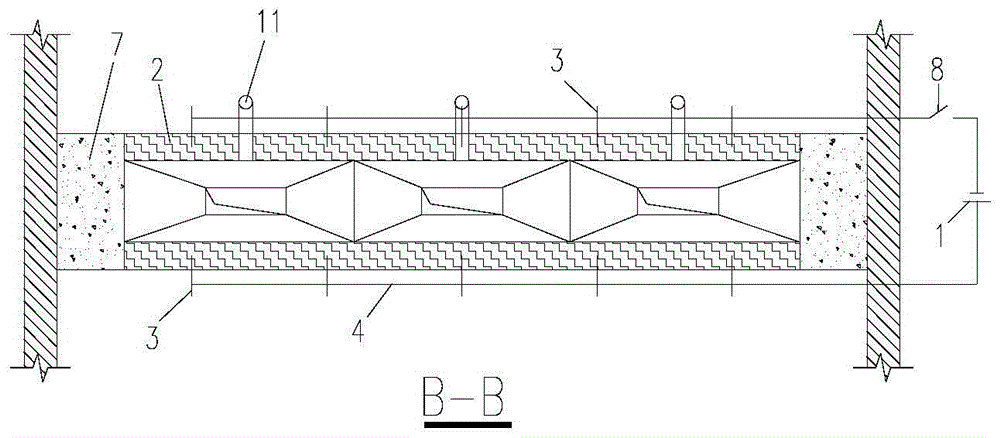

[0016] The front and rear wall panels 2 of the hollow wall of a carbon fiber conductive concrete wall-type dust removal device of the present invention are made of carbon fiber conductive concrete, which is equivalent to capacitor plates. The strip electrodes that are vertically embedded in the front and rear wall panels 2 to form electrical circuits are carried out. Power on, the two pole plates of the device respectively generate positive and negative charges. At this time, the fan 10 is used, and the fan 10 can provide a speed of v 1 =0.5m / s airflow, suck the dust particles in the environment into the hollow wall. When the dust particles pass through the comb electrode 9 at the entrance of the hollow wall, they are respectively given a positive or negative charge, with a little dust The particles enter the hollow channel of the hollow wall. Due to the electric field ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com