Process of preparing high-chromium alloy supper 13-Cr seamless steel tubes through CPE (cross-roll piercing and elongation) hot rolling mill

A technology of seamless steel pipe and high chromium alloy, which is applied in the field of metal rolling to achieve the effect of small deformation resistance, fast deformation speed and guaranteed product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

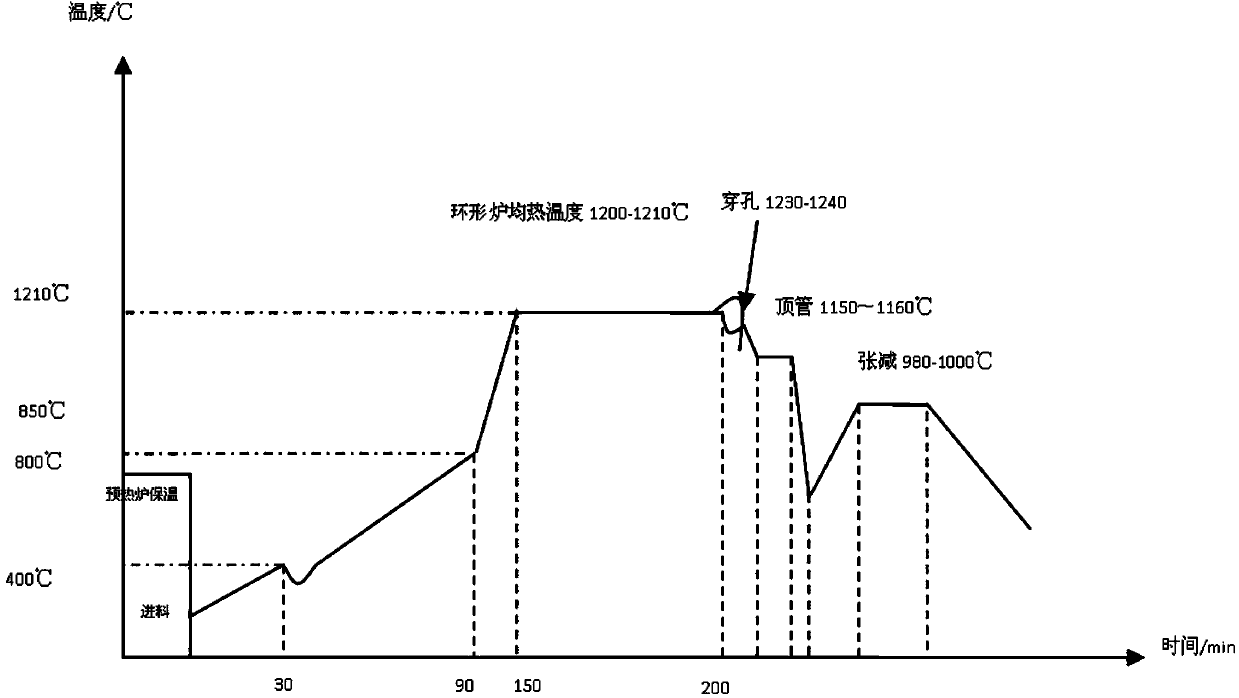

[0024] In order to make the content of the present invention easier to be understood clearly, the following further describes the present invention in detail based on specific embodiments in conjunction with the accompanying drawings.

[0025] The finished steel pipe specifications of this embodiment: φ88.9×6.45×10000-11500mm;

[0026] Tube billet specifications: φ125×1630mm;

[0027] Billet material: 13Cr;

[0028] The general steps of the manufacturing process are: bright tube → pickling and grinding → tube blank material cutting → cold centering → tube blank preheating → ring furnace heating → tube blank perforation → capillary necking → tube jacking → loose rod → stripping →Hot sawing→Reheating→Tension reduction→Cooling bed cooling→Table inspection→Flaw detection→Packing and storage.

[0029] A process for preparing a high-chromium alloy super 13Cr seamless steel pipe by a hot-rolling CPE unit. The process steps are as follows:

[0030] a) Provide a tube blank;

[0031] b) After pick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com