Rapid cutting tool

A rapid cutting and cutting tool technology, which is applied to lathe cutting tools, manufacturing tools, tool holder accessories, etc., can solve the problems of easy damage of cutting tools, increase the burden of enterprises, and large cutting resistance, etc., and achieve long service life and high Strength, cutting resistance reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

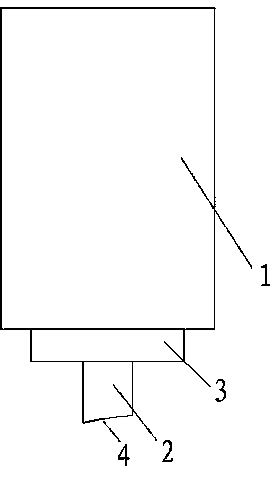

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 Shown, a kind of fast cutting cutter comprises cutter body 1 and cutter head 2, is provided with cutter head 2 at the bottom of cutter body 1, is provided with blade 4 at the bottom of cutter head 2, and described blade 4 and cutter head 2 bottom The included angle of the horizontal line is an acute angle, and a rubber plate 3 is sleeved on the cutter head 2, and the cutter head 2 is made of YT30 tungsten-titanium-cobalt cemented carbide. The thickness of the rubber sheet 3 is 1 / 4 of the length of the cutter head 2 . The length of the cutter body 1 is 4cm-6cm. The length of the cutter head 2 is 1.5cm-2.5cm. The included angle between the blade 3 and the horizontal line at the bottom of the cutter head 2 is less than 15 degrees.

[0014] The rapid cutting tool of the present invention has an acute angle between the blade 3 and the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com