Technology for machining locomotive bogie frame

A locomotive bogie and processing technology, applied in the field of locomotive bogie frame processing technology, can solve problems such as processing error, center misalignment, affecting frame assembly quality, etc., to achieve easy operation, ensure stability, improve machining quality and The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

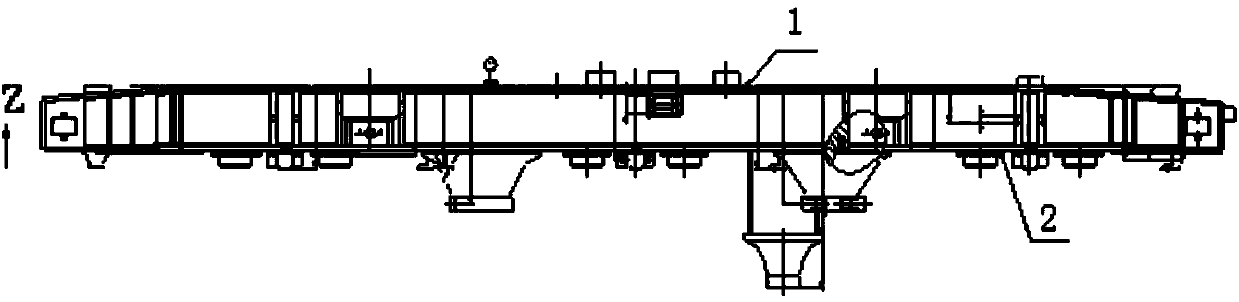

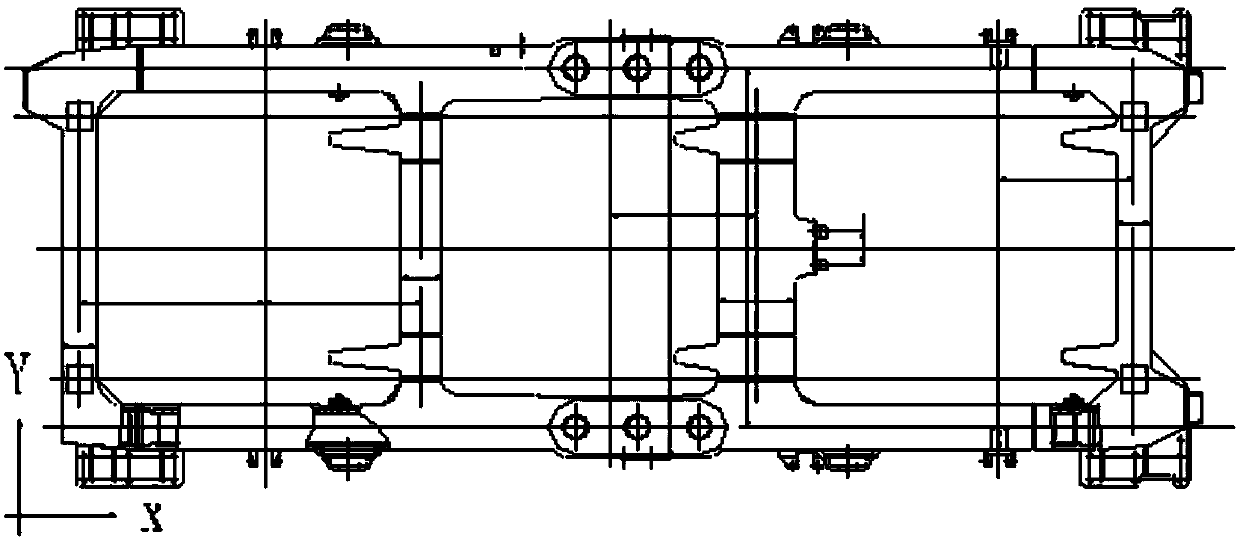

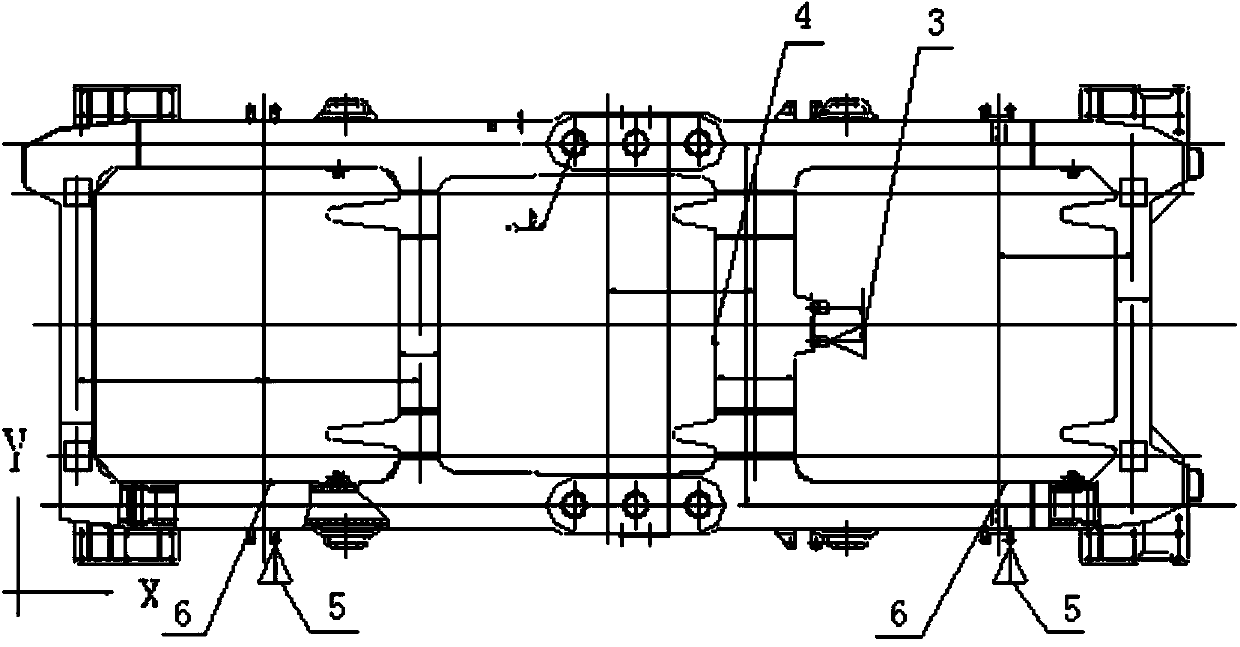

[0022] see image 3 with Figure 4 , In the processing technology of the locomotive bogie frame in this embodiment, first draw the horizontal X and vertical Y centerlines on the frame and align them to determine the coordinate positions of the frame in the X and Y directions. Then, to locate on the blank surface of the frame, on the basis of the existing positioning and clamping in the vertical Z (up and down) direction, add positioning tooling and clamping points in the X, Y (left and right) directions (X direction positioning points 3, X Clamping point 4, Y-direction positioning point 5, Y-direction clamping point 6), so as to ensure the stability of the frame during the process of processing a series of surfaces 2. After processing each processing position on a series of surfaces 2, the frame is adjusted. Then use the processed first-series surface 2 for positioning, no need to re-align again, just use the tooling to position on the processed first-series processing surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com