Dual mode control device and control method thereof for wheel type engineering machinery traveling system

A technology of driving and control devices for construction machinery, applied in the field of dual-mode control devices, can solve the problems of high labor intensity for drivers and difficulty in improving work production efficiency, so as to save engine power waste, improve operation accuracy and control precision, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

[0044] Since this patent is common to wheeled construction machinery that forms a travel transmission system such as hydraulic drive, hydraulic drive, or power gearbox, this specific embodiment takes a hydraulically driven motor grader as an example for patent description.

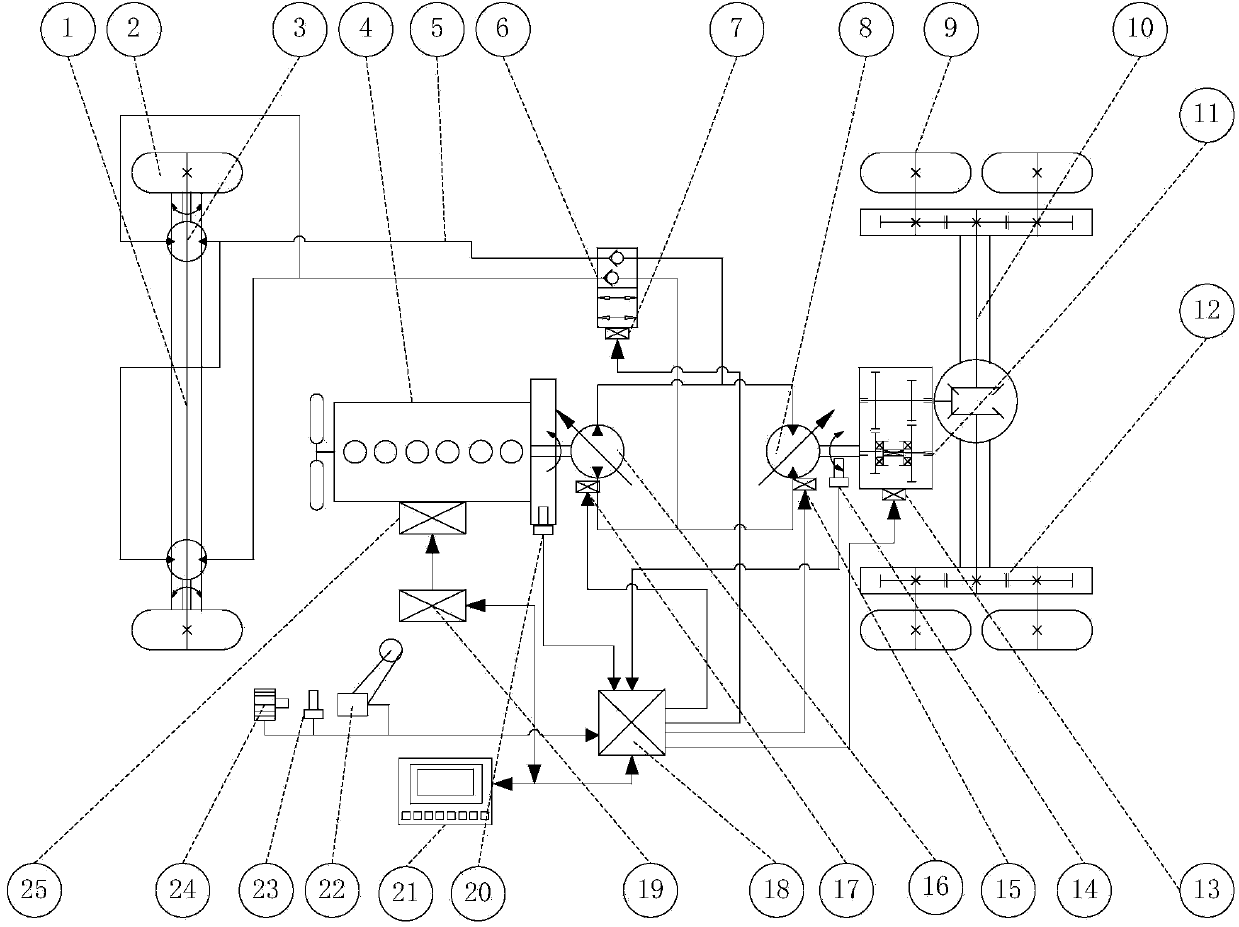

[0045] see figure 1 , a dual-mode control device for a wheeled construction machinery driving system, the wheeled construction machinery driving system includes: a front axle 1, a front wheel 2, a front axle motor 3, an engine 4, a hydraulic pipeline 5, a hydraulic valve 6, Hydraulic valve solenoid valve 7, rear axle motor 8, drive wheel 9, rear axle 10, gearbox 11, balance box 12, shift solenoid valve 13, rear axle motor solenoid valve 15, travel pump 16, travel pump solenoid valve 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com