Pretreatment system and pretreatment method for high-concentration refractory organic wastewater

An organic wastewater, refractory technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of iron-carbon scab, inoperability, easy consumption, etc., to achieve Improved biochemical properties, prevention of iron-carbon scab, and improved degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

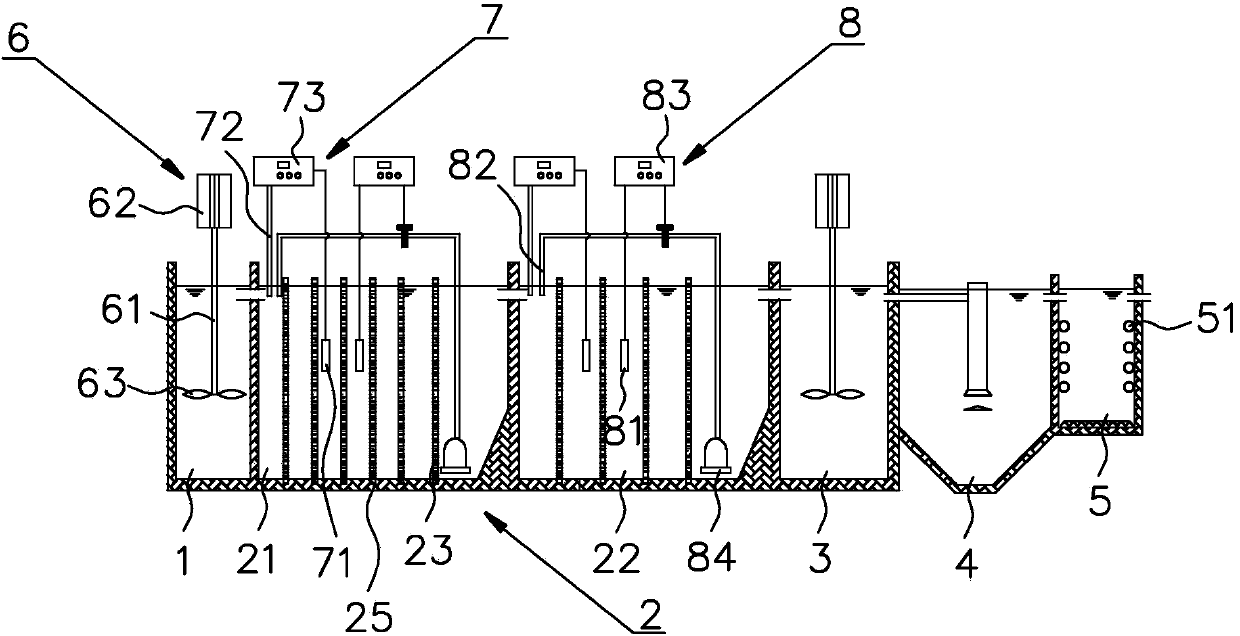

[0036] Example 1 High concentration refractory organic wastewater pretreatment system

[0037] Such as figure 1 As shown, this embodiment is a high-concentration refractory organic wastewater pretreatment system, including a carbon particle dosing pool 1, an iron-carbon micro-electrolysis pool 2, a pH adjustment pool 3, a sedimentation pool 4, and nano-TiO 2 Photocatalytic pool5.

[0038] The carbon particle dosing pool 1 is provided with a stirring device 6, which includes a stirring shaft 61 extending into the waste water, a motor 62 that drives the stirring shaft 61 to rotate, and a stirring paddle 63 installed on the stirring shaft 61. The stirring device 6 is used to fully mix the activated carbon particles in the carbon particle dosing pool 1 in the waste water, and then flow into the iron-carbon micro-electrolytic cell 2 .

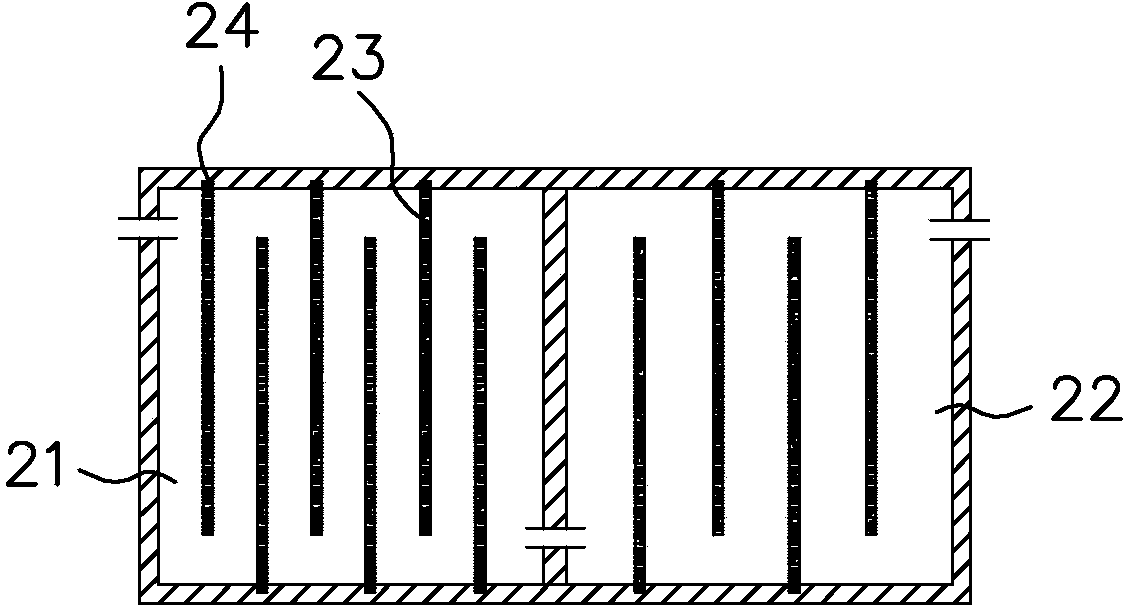

[0039] Depend on figure 1 It can be seen that baffles 23 are detachably installed in the iron-carbon micro-electrolytic cell 2, and the baffles ...

Embodiment 2

[0047] Embodiment 2 high concentration refractory organic wastewater pretreatment method

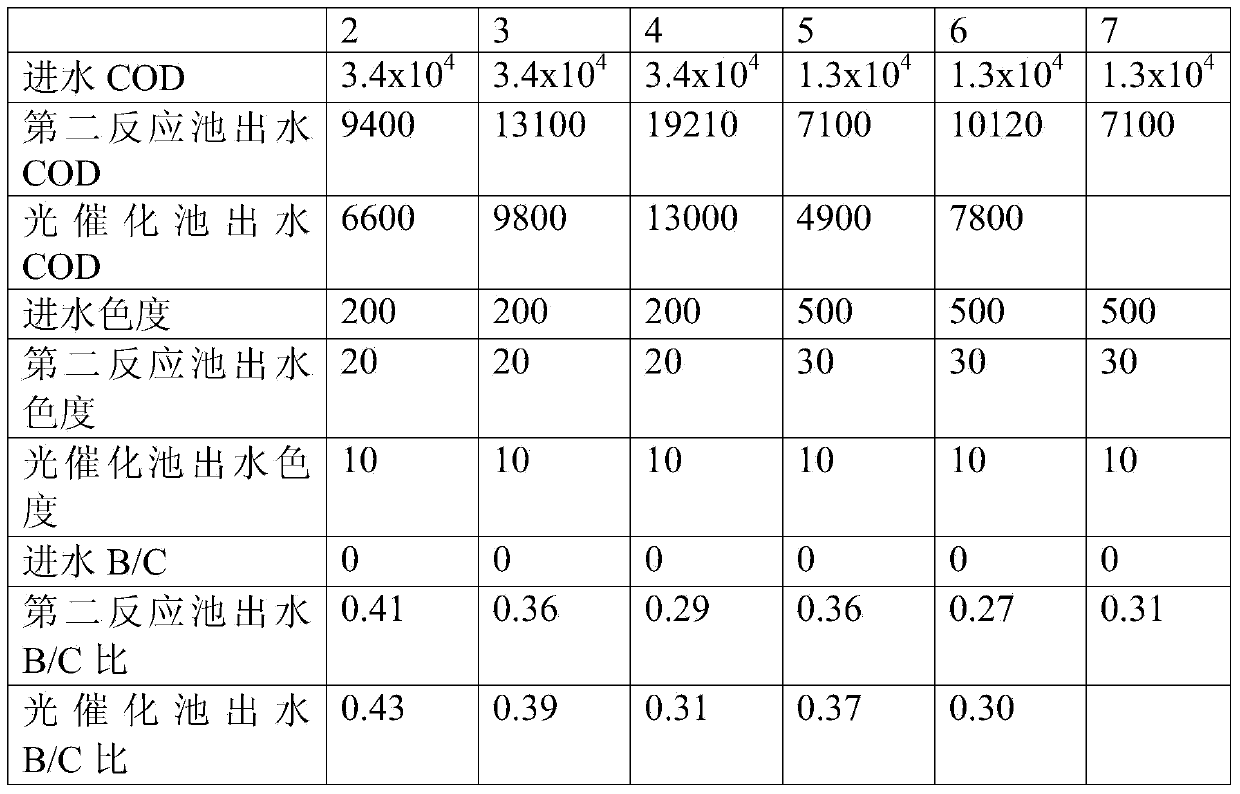

[0048] Utilize the pretreatment system of embodiment 1 to carry out pretreatment to the high concentration refractory organic wastewater sample in table 1:

[0049] Table 1 Salinity, COD, and chromaticity indicators in water samples

[0050] substance COD (mg / L) Chroma (times) B / C ratio pH concentration 3.4×10 4 200 0 5.6

[0051] COD in wastewater is mainly provided by phenol (toxic, difficult to be degraded by microorganisms), pretreatment includes the following steps:

[0052] (1) Introduce the wastewater into the carbon particle dosing tank, adjust the pH value of the wastewater to be treated to 3, and add carbon particles to a concentration of 50g / L at the same time, and mix them evenly through the stirring device;

[0053] (2) Introduce the effluent from the carbon particle dosing tank into the first reaction tank. The distance between two adjacent...

Embodiment 3

[0057] Embodiment 3 high-concentration refractory organic wastewater pretreatment method

[0058] Utilize the pretreatment system of embodiment 1 to carry out pretreatment to the high-concentration refractory organic wastewater sample in table 1, pretreatment comprises the following steps:

[0059] (1) Introduce the wastewater into the carbon particle dosing tank, adjust the pH value of the wastewater to be treated to 4, and add carbon particles to a concentration of 30g / L at the same time, and mix them evenly through the stirring device;

[0060] (2) Introduce the effluent from the carbon particle dosing tank into the first reaction tank, the distance between two adjacent baffles in the first reaction tank is 5cm, the pH value is 4, the carbon particle concentration is 30g / L, and the hydraulic retention time for 2h;

[0061] (3) The effluent from the first reaction tank is introduced into the second reaction tank. The distance between two adjacent baffles in the second react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com