Dehydration method of heterogeneous sludge

A heterogeneous, sludge technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of difficulty in dewatering, reducing water content, low efficiency, etc., saving dewatering time, increasing production speed, and improving dewatering efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

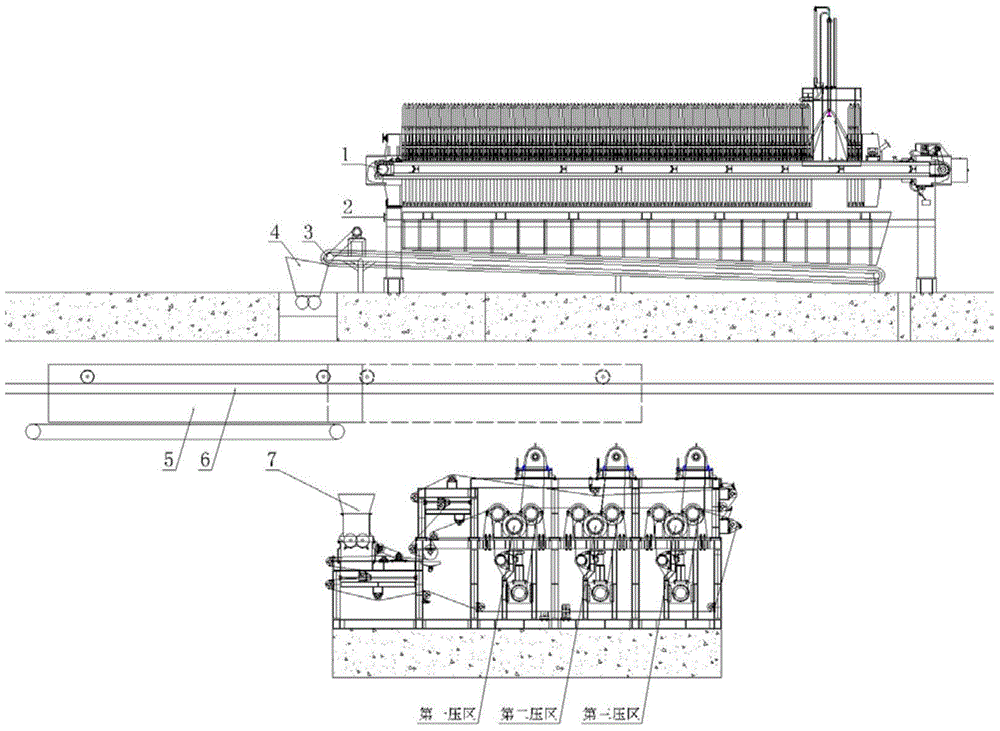

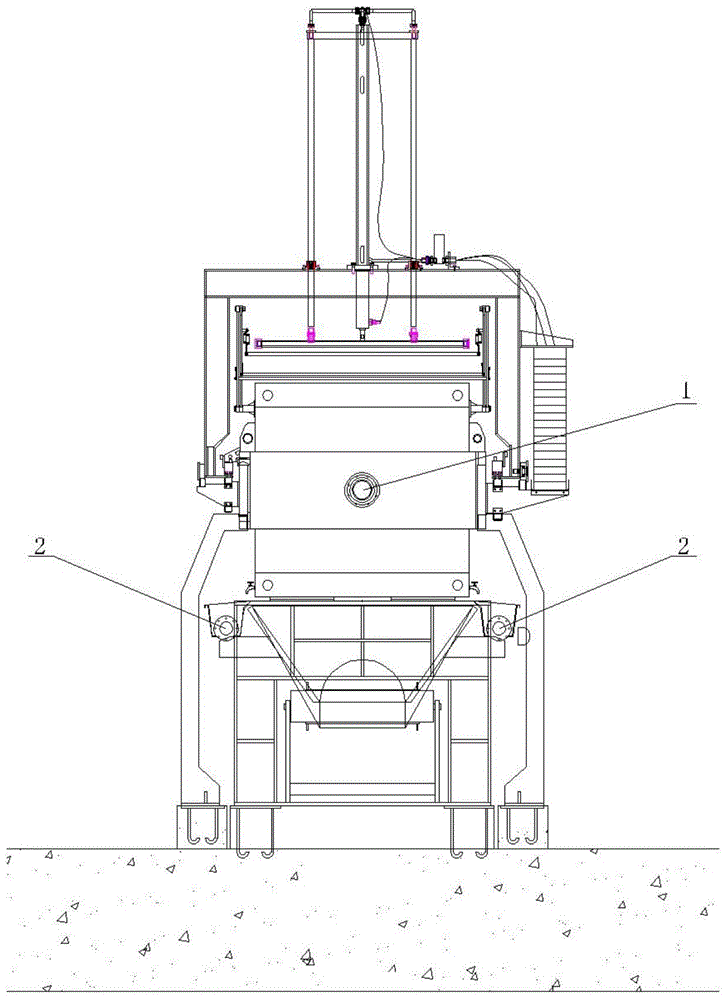

[0018] Embodiment 1: as figure 1 and figure 2 As shown, a method for dewatering heterogeneous sludge. When the equipment is running, the untreated mixed sludge and slaked lime are mixed and stirred in the sludge conditioning tank. The weight ratio of the mixed sludge to slaked lime is 1:0.1 , the stirring time is 10 minutes; transport the stirred mixed material into the sludge feed pump, and add dehydrating agent, the weight ratio of material and dehydrating agent is 1:0.001; In the box of the filter press, pre-dehydration is carried out. The dehydration time is 60 minutes. The mixed material is dehydrated through the box filter press to obtain a sludge filter cake with a moisture content of 60%-65%. The dehydrated water is discharged from the outlet 2 discharge, after the sludge filter cake leaves the chamber filter press, the filter cake is peeled off to the belt conveyor 3, and then transported to the feed crusher 4 for crushing, so that the sludge filter cake particles a...

Embodiment 2

[0019] Embodiment 2: as figure 1 and figure 2 As shown, a method for dewatering heterogeneous sludge. When the equipment is running, the untreated mixed sludge and slaked lime are mixed and stirred in the sludge conditioning tank. The weight ratio of the mixed sludge to slaked lime is 1:0.1 , the stirring time is 20 minutes; the mixed material after stirring is transported into the sludge feed pump, and a dehydrating agent is added, and the weight ratio of the material and the dehydrating agent is 1:0.003; In the box of the filter press, pre-dehydration is carried out. The dehydration time is 60 minutes. The mixed material is dehydrated through the box filter press to obtain a sludge filter cake with a moisture content of 60%-65%. The dehydrated water is discharged from the outlet 2 discharge, after the sludge filter cake leaves the chamber filter press, the filter cake is peeled off to the belt conveyor 3, and then transported to the feed crusher 4 for crushing, so that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com