Compound nitrogen protective agent as well as preparation method and application thereof

A compound nitrogen and protective agent technology, which is applied in the application, preparation of test samples, fertilizer mixture, etc., can solve the problems of nitrogen loss and other problems, and achieve the effect of excellent coefficient of variation, cost reduction, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

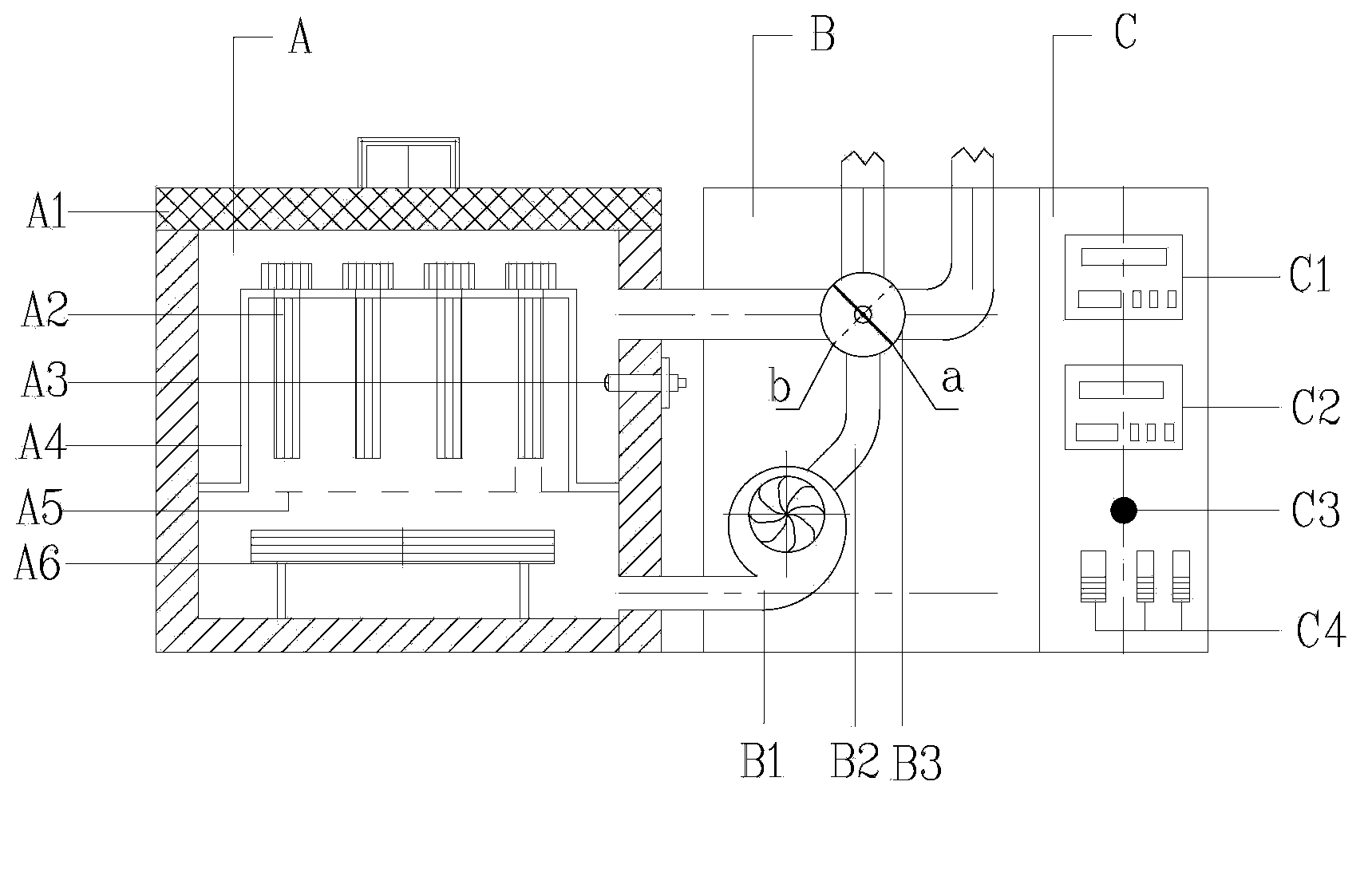

Image

Examples

preparation example Construction

[0043] The preparation method of described compound nitrogen protection agent, comprises the steps:

[0044] (1) Take hydrochloric acid and add water at a volume ratio of 1:1 to prepare dilute hydrochloric acid, and dissolve quantitative Li, Sr, and Be in dilute hydrochloric acid;

[0045] (2) Heat to 40-60°C, keep warm for 20-40 minutes, then cool to room temperature;

[0046](3) Add acetic acid, heat to 60-80°C, keep warm for 20-40 minutes, then cool to room temperature;

[0047] (4) Add sulfuric acid and shake well;

[0048] (5) Add sodium chloride, mix evenly and store;

[0049] (6) The shelf life is six years.

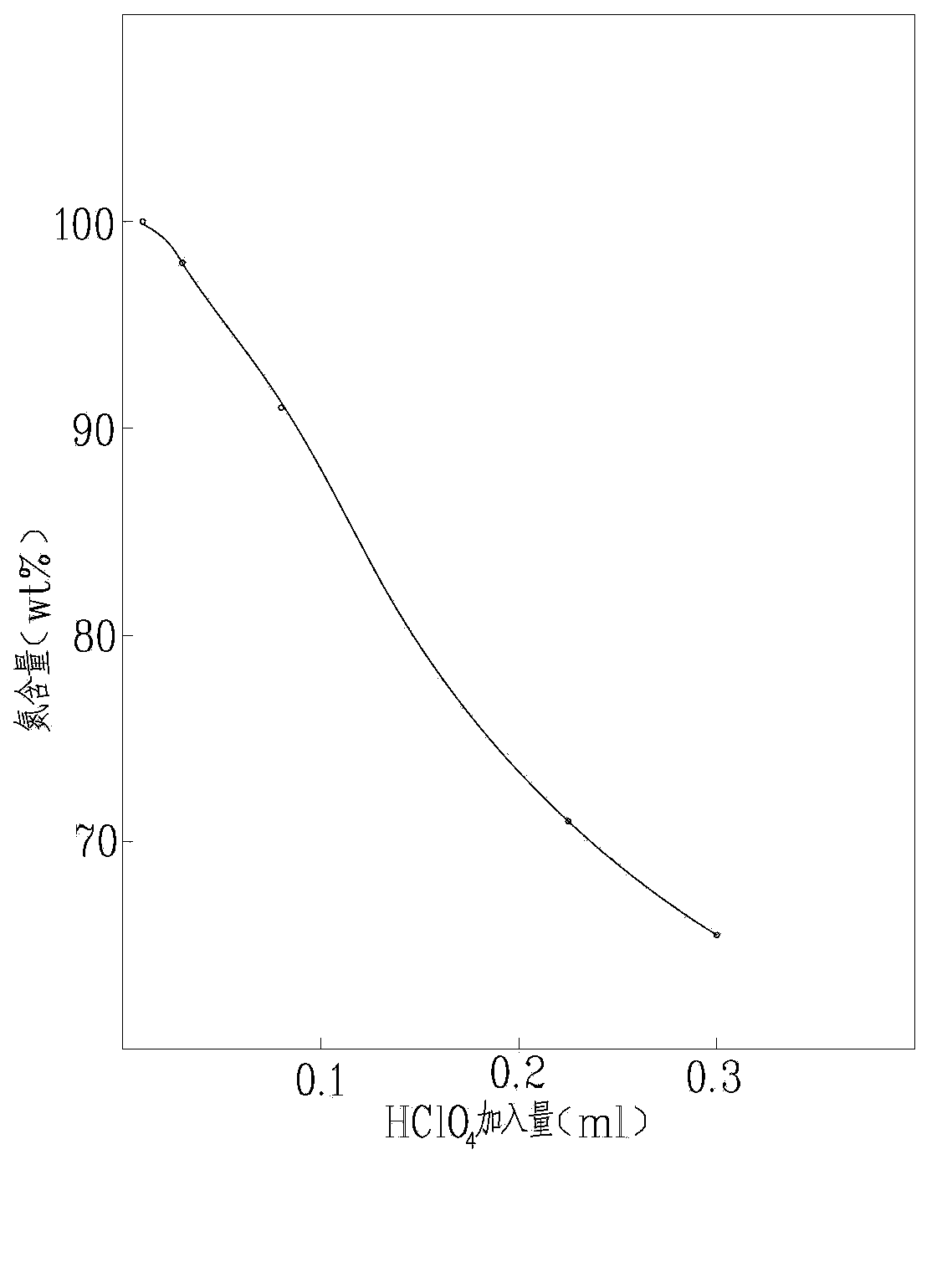

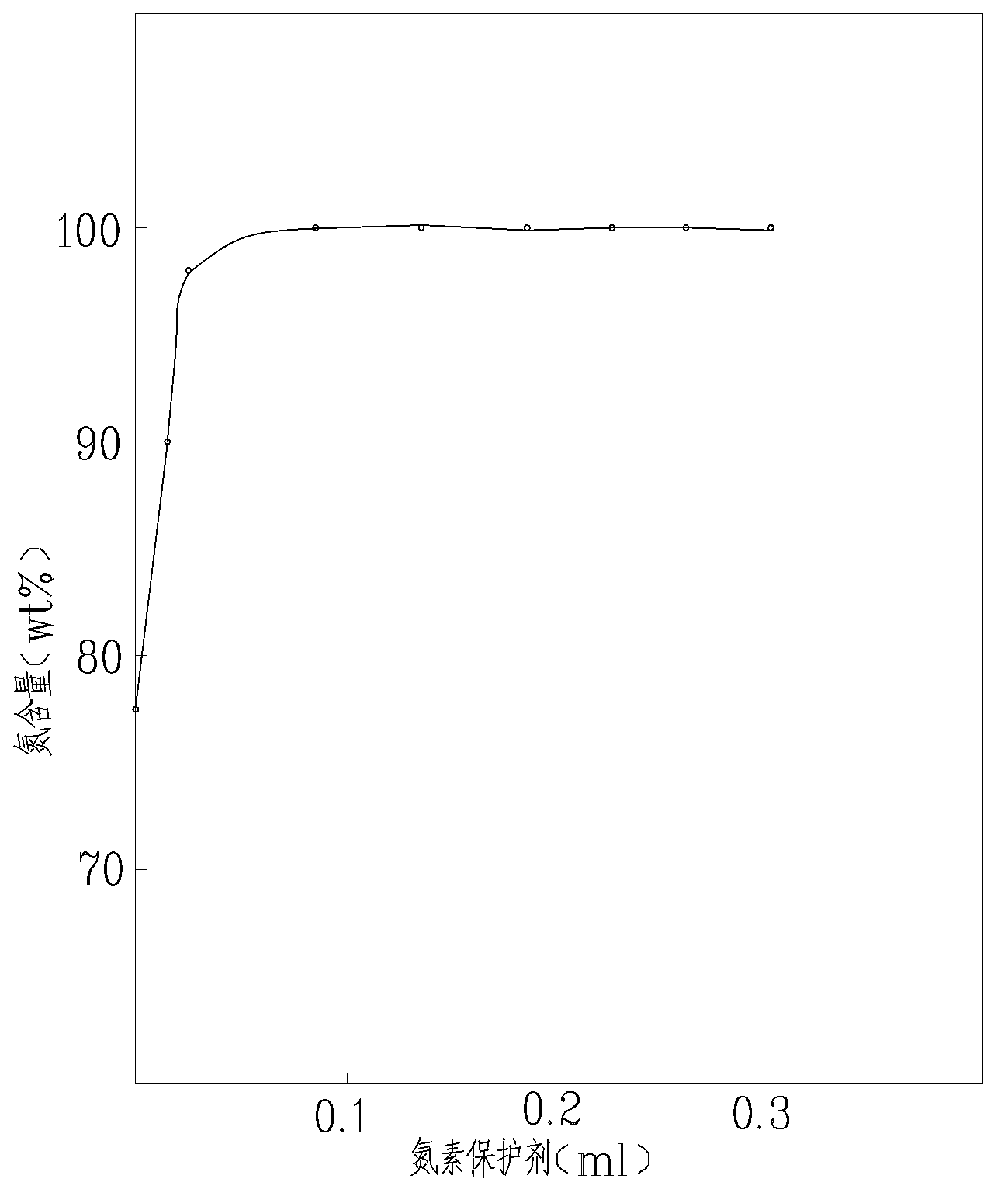

[0050] Weigh 0.3000 g of the sample with a ten-thousandth balance, and place it in a Teflon-sealed digestion tube. Add nitrogen protection agent 0.2ml and shake well, the digestion solution uses: H 2 SO 4 ,3-5ml+HF,1-2ml+HClO 4 ,0.2-0.4ml, add H first 2 SO 4 , add HF, and finally add HClO 4 . Cover the Teflon-sealed digestion tube with the sealing cap, ...

Embodiment 1

[0067] The composite nitrogen protective agent of this embodiment, its composition and preparation process are as follows:

[0068] Hydrochloric acid HCl (concentration 37wt%) 10ml, acetic acid CH 3 COOH (concentration 99.8wt%) 100ml, sulfuric acid H 2 SO 4 (concentration 98wt%) 90ml, high-purity rare metals (concentration above 99.9wt%): lithium Li 2 mg, strontium Sr 3 mg, beryllium Be 4 mg; sodium chloride 1 g.

[0069] (1) Dissolve 2 mg of Li, 3 mg of Sr, and 4 mg of Be in 10 ml of hydrochloric acid with a concentration of 37 wt %;

[0070] (2) Heat to 50°C, keep warm for 30 minutes, then cool to room temperature;

[0071] (3) Add 900ml of acetic acid with a concentration of 99.8wt%, heat to 70°C, keep warm for 30 minutes, and cool to room temperature;

[0072] (4) Add 90ml of sulfuric acid with a concentration of 98wt%, and shake well;

[0073] (5) Add 1 gram of sodium chloride, mix evenly and store.

[0074] Such as figure 2 As shown, accurately weigh 0.3000g of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap