Reactive resin adhesive and synchronous rubble scattering machine

A technology of synchronizing crushed stone and resin glue, applied in construction, road, road repair, etc., can solve the problems of inability to apply for spraying work, short curing time, etc., and achieve the effect of cost reduction, short curing time and good anti-corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

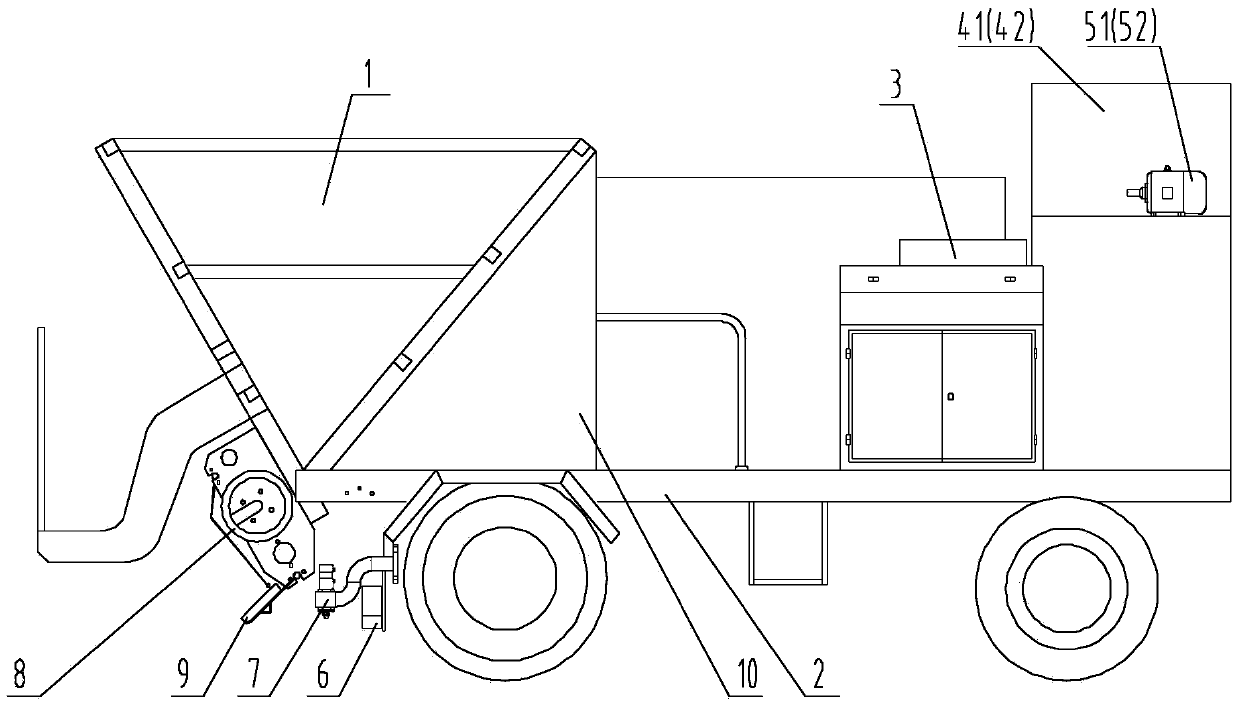

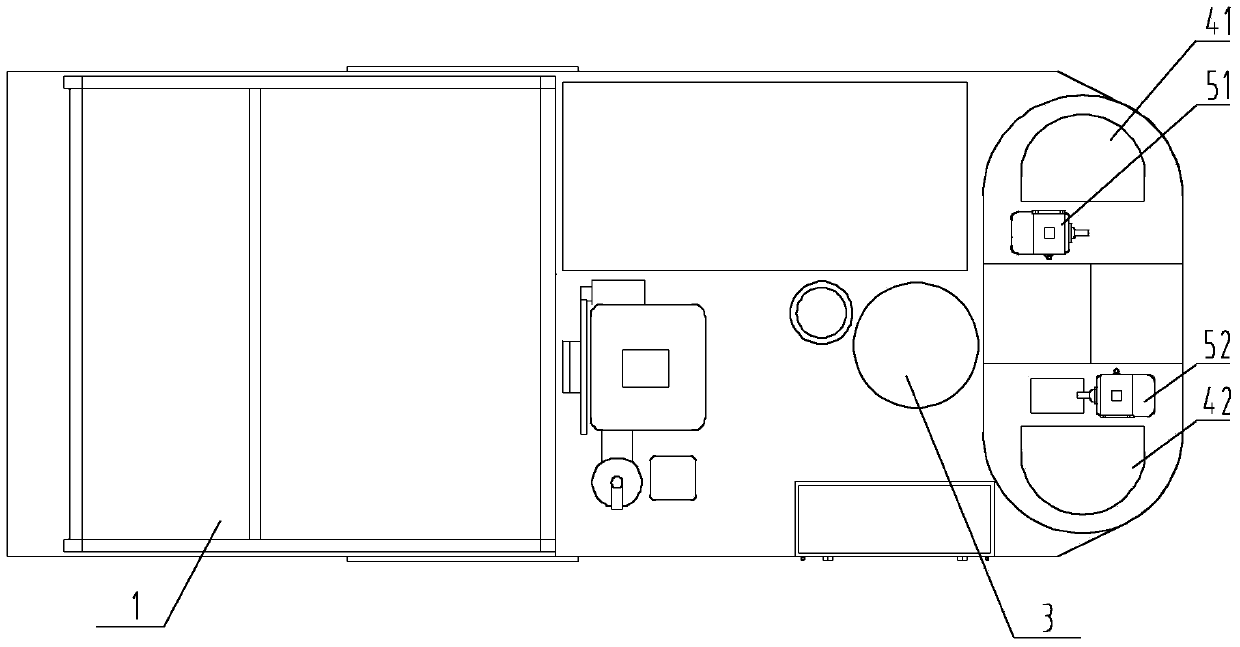

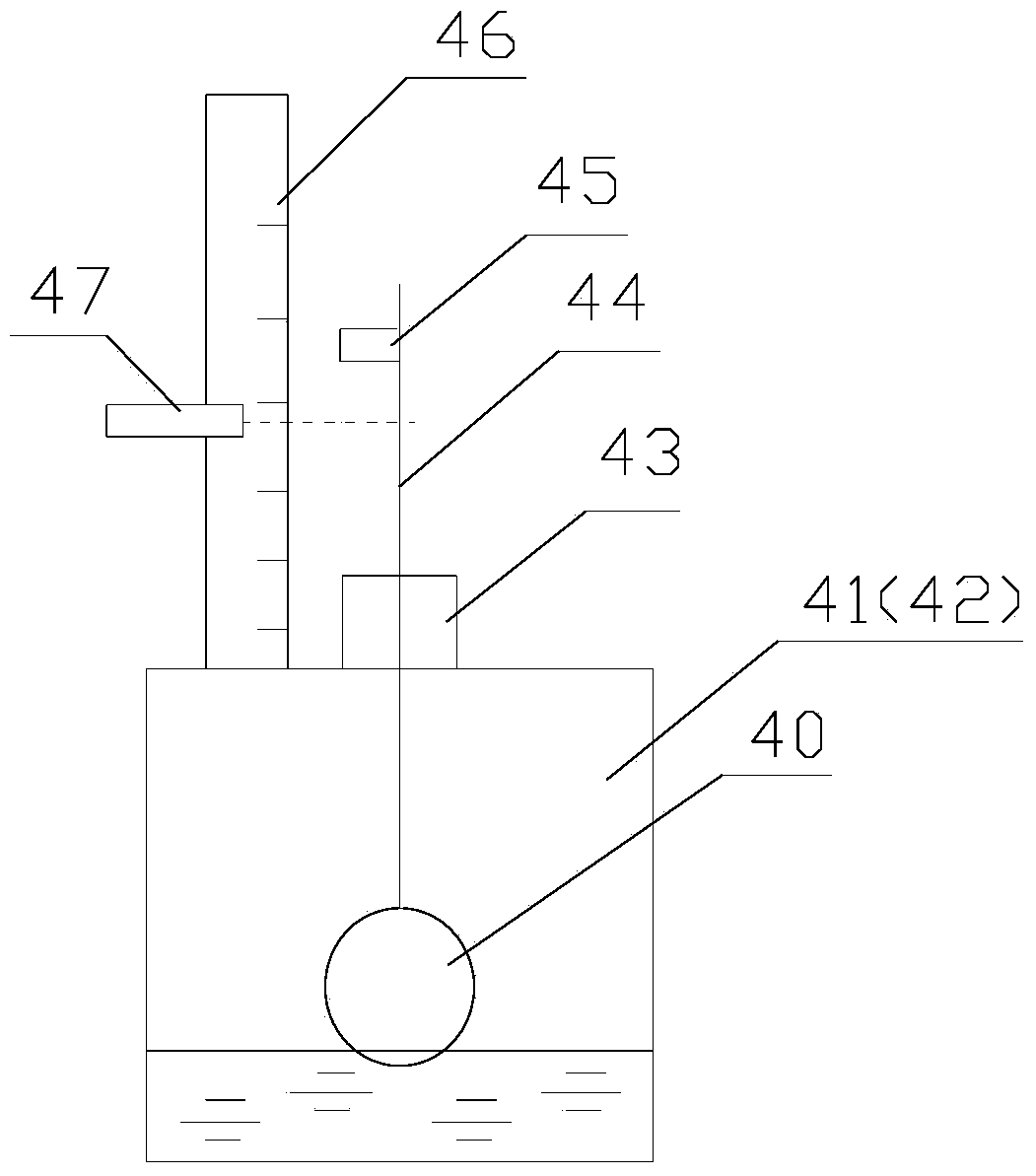

[0032] like figure 1 and figure 2 As shown, the synchronous gravel spreader of the present invention includes a traveling frame 2 with wheels, and the frame 2 is provided with an A storage tank 41 and a B storage tank 42 for storing A and B components at the front, and the rear is provided with There is a crushed stone bin 1, and components A and B are input into the mixing drum 3 by air pumps 51 and 52 in a ratio of close to 1:1 for mixing and stirring. 7. Spray to the ground; at the same time, the gravel in the gravel bin 1 can be evenly distributed through the roller 8 and the guide plate 9 below the sprinkler and then fall to the ground.

[0033] Among them, component A is glycidyl ester epoxy resin, and component B is composed of the following raw materials and weight percentages: polyamine curing agent 60-69%, polysulfide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com