Environment-friendly warm-mixing flame-retardant composite modifier for asphalt pavement

A flame retardant compounding and modifier technology, applied in building thermal insulation materials, building components, climate change adaptation and other directions, can solve the problems of poor driving comfort, high production temperature conditions, complicated addition processes, etc. Simple and convenient, reduce production temperature, improve the effect of driving environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

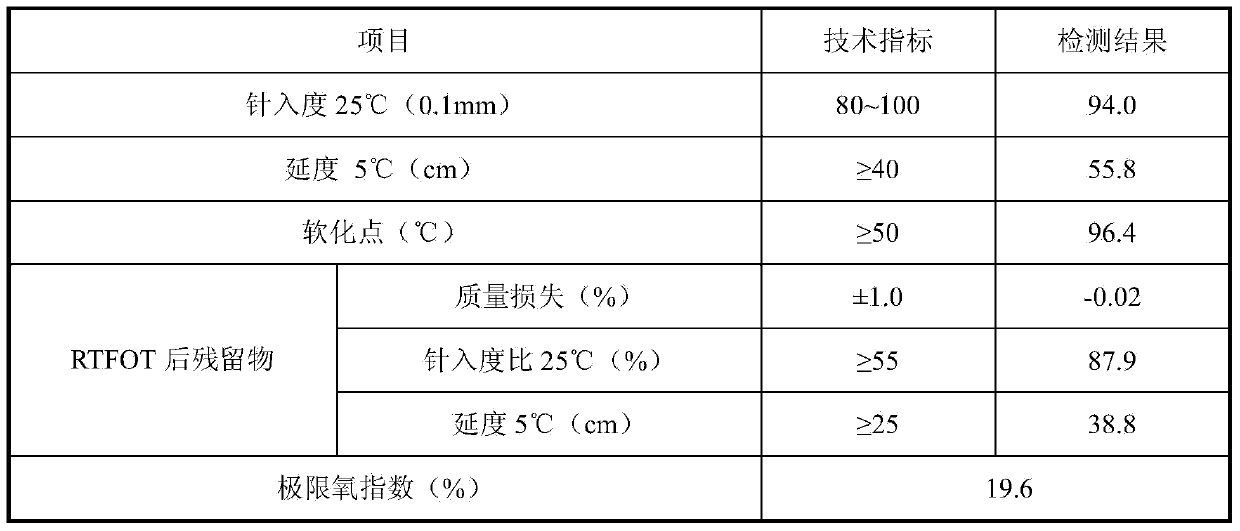

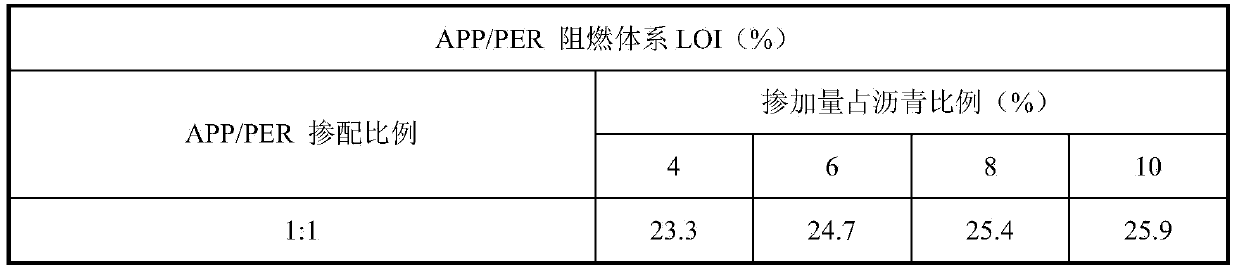

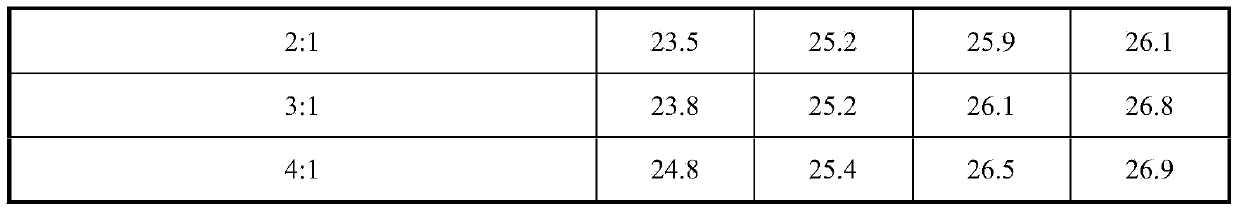

Embodiment 1

[0062] The modifier of this embodiment is composed of materials in the following weight ratios: APP: 32%, PER: 8%, MH: 9%, Sb 2 O 3 : 3%, zeolite: 40%, nano-TiO 2 : 4%, tourmaline powder: 4%. The mixing amount is 16% of the asphalt mass.

Embodiment 2

[0064] The modifier of this embodiment is composed of materials in the following weight ratios: APP: 31%, PER: 9%, MH: 9%, Sb 2 O 3 :3%, zeolite: 41%, nano-TiO 2 : 4%, tourmaline powder: 3%. The mixing amount is 15% of the asphalt mass.

Embodiment 3

[0066] The modifier of this embodiment is composed of materials in the following weight ratios: APP: 30%, PER: 8%, MH: 8%, Sb 2 O 3 :3%, zeolite: 42%, nano-TiO 2 : 4.5%, tourmaline powder: 4.5%. The mixing amount is 15% of the asphalt mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com