Motor decelerator test system

A test system and reducer technology, applied in fluid pressure actuation system testing, mechanical equipment, fluid pressure actuation devices, etc., can solve problems such as high price, low recovery efficiency, unstable test speed, etc., and achieve stable increase performance, and the effect of improving energy recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention. In addition, the embodiments in this section and the features in the embodiments can be combined with each other under the condition of no conflict.

[0046] Please refer to figure 1 , the present invention will be described in further detail below in conjunction with embodiment.

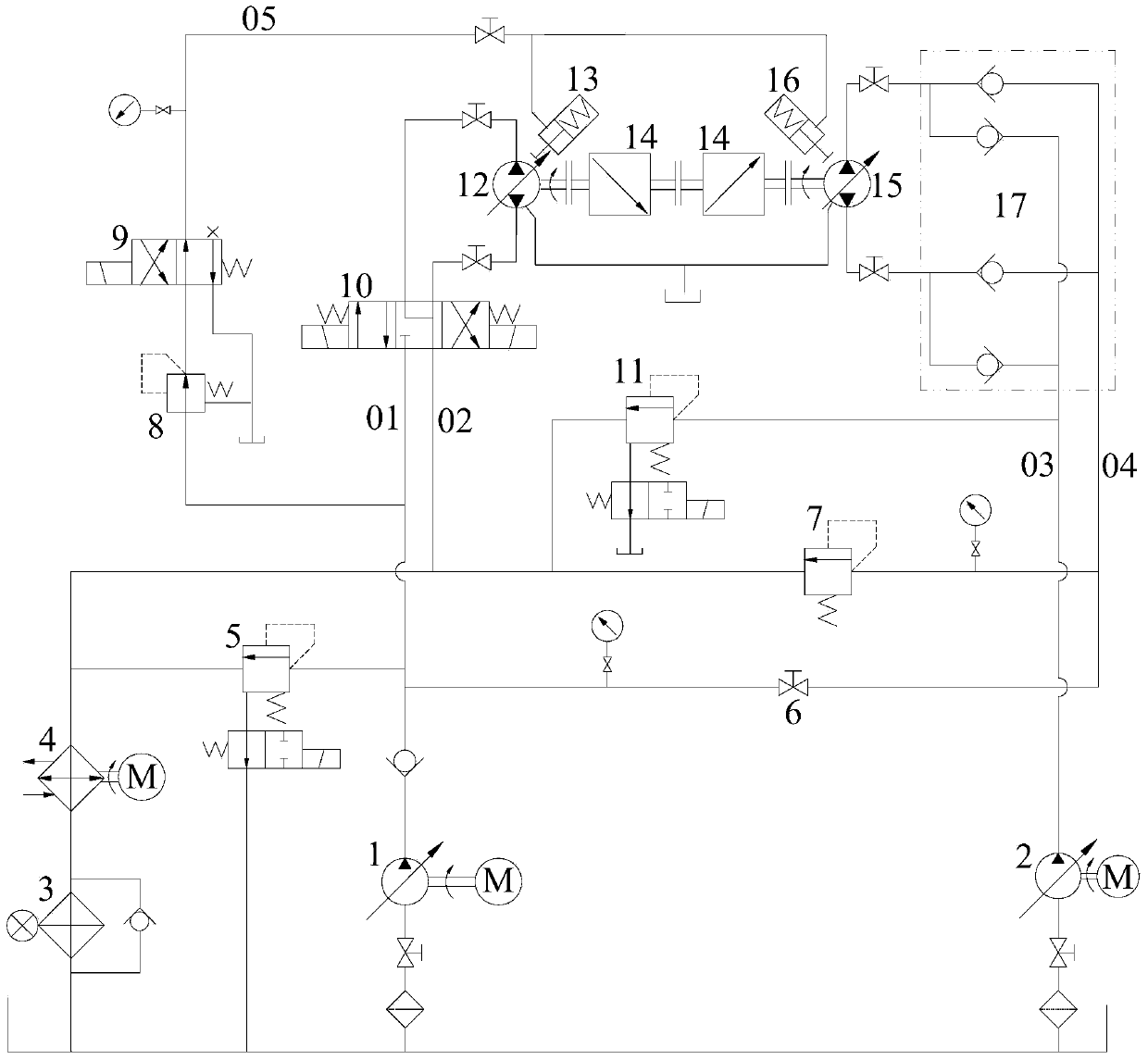

[0047] Such as figure 1 As shown, the motor reducer test system of this embodiment at least includes the first oil circuit 01, the second oil circuit 02, the third oil circuit 03, the fourth oil circuit 04, the first relief valve 11, the tested motor reducer 12 and loading motor reducer 15.

[0048] Wherein, the power shaft of the loading motor speed reducer 15 is connected with the power shaft of the tested motor speed reducer 12. power shaft connection.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com