Compensation system, high-order aspheric surface detection device and method

A technology of high-order aspheric surface and compensation system, applied in the field of optical aspheric surface detection, can solve the problem of low accuracy, achieve the effects of reliable and effective detection accuracy, reduced processing and assembly accuracy requirements, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

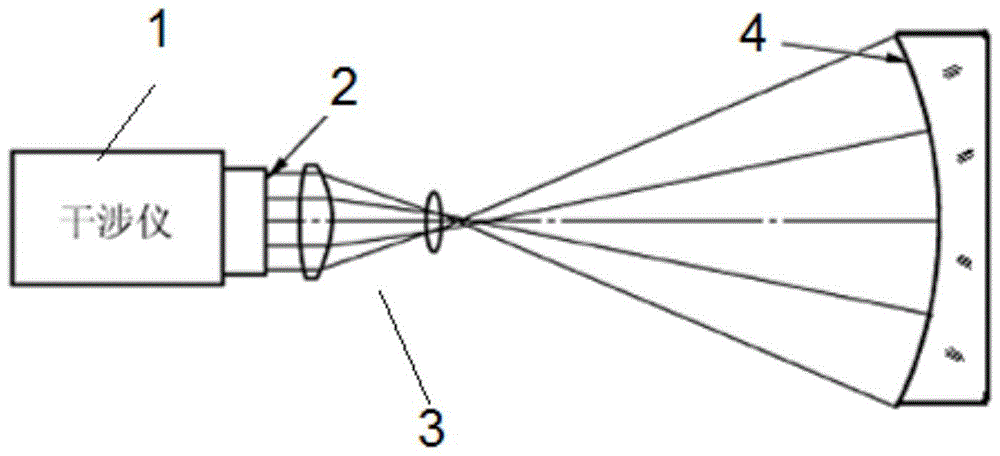

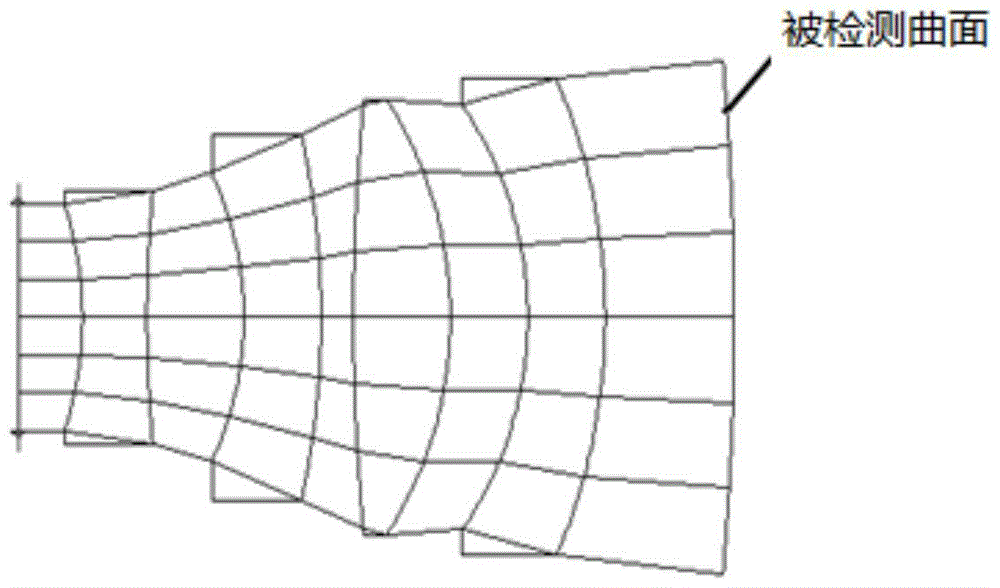

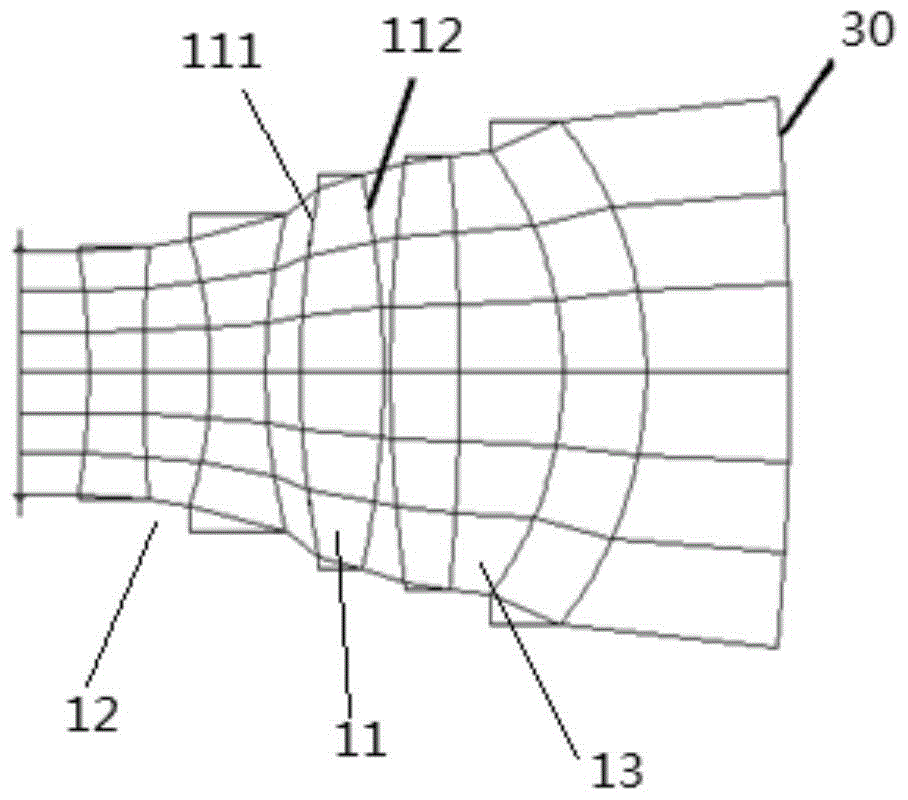

[0030] As mentioned in the background art, in the manufacturing process of the high-order aspheric mirror, the detection of the high-order aspheric surface is quite a key technology. Most of the existing high-order aspheric detection technologies use the interference detection method. In this method, in order to improve the compensation ability for high-order aspheric surfaces with large deviation and large relative aperture, it is often necessary to use multiple aspheric optical lenses to form a compensation system. However, there will be errors in the dimensions of each optical lens when it is manufactured, and there are assembly alignment errors between the lenses. Therefore, with the increase in the number of optical lenses, the error of the compensation system itself is continuously enlarged. Taking 6 aspheric lenses as an example, even if each lens is prepared with extremely strict requirements, after these lenses are assembled together, it can cause The error can still...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com