Method for boiler real-time on-line monitoring-based measurement of optimum work efficiency of generator set

A technology of generator set and work efficiency, applied in the direction of internal combustion engine testing, etc., can solve problems such as calculation result method error, avoid deviation, and realize the effect of automatic optimization of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

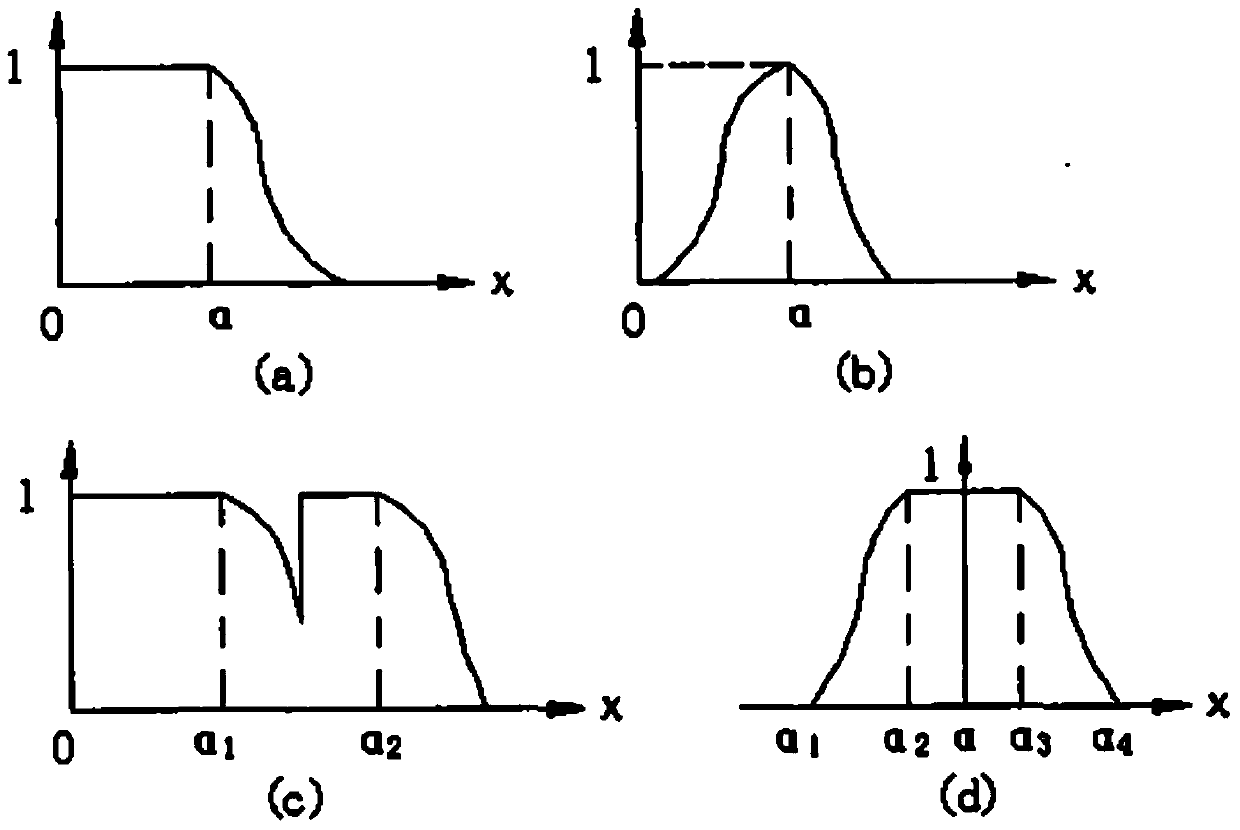

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

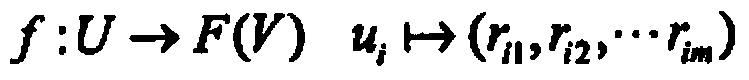

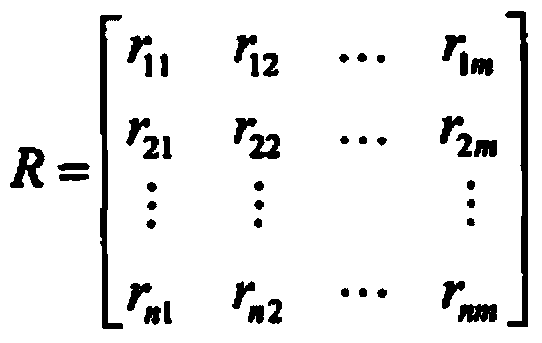

[0017] In the coal-fired boiler performance real-time on-line monitoring measurement method of the present invention, as long as the O 2 Composition and measuring one of the coal feed rate of the pulverizing system when the product is exported, the total air volume when the product is exported, and the flue gas volume during the material output process, and according to the above measurement results without using the boiler output heat as the measured value, Establish corresponding empirical equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com