Steam dryness test method and device

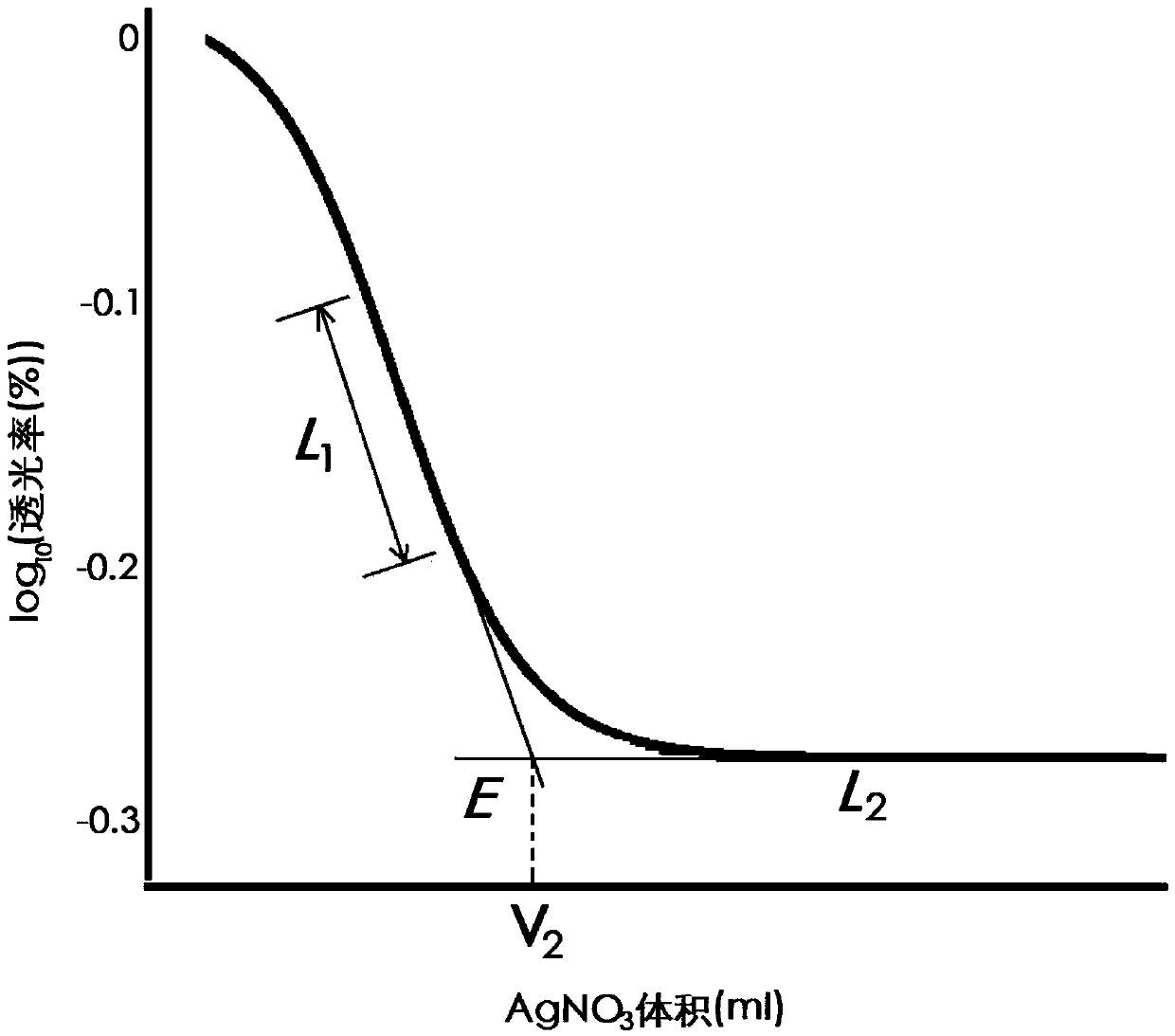

A dryness and steam technology, which is applied in the analysis by chemical reaction of materials, and material analysis by observing the influence on chemical indicators, can solve the problem of high labor cost, unstable titration process speed, and determination of dryness. Error and other problems, to achieve the effect of simple operation, reducing the influence of human factors and the environment, and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Perform the following steps to measure steam dryness.

[0049] 1. Fold the qualitative filter paper into a trumpet shape, place it in a ¢75mm long-necked glass funnel, and insert the funnel into a 100ml Erlenmeyer flask A.

[0050] 2. Pour the steam condensed water sample into the funnel and let it pass through the qualitative filter paper into the Erlenmeyer flask A.

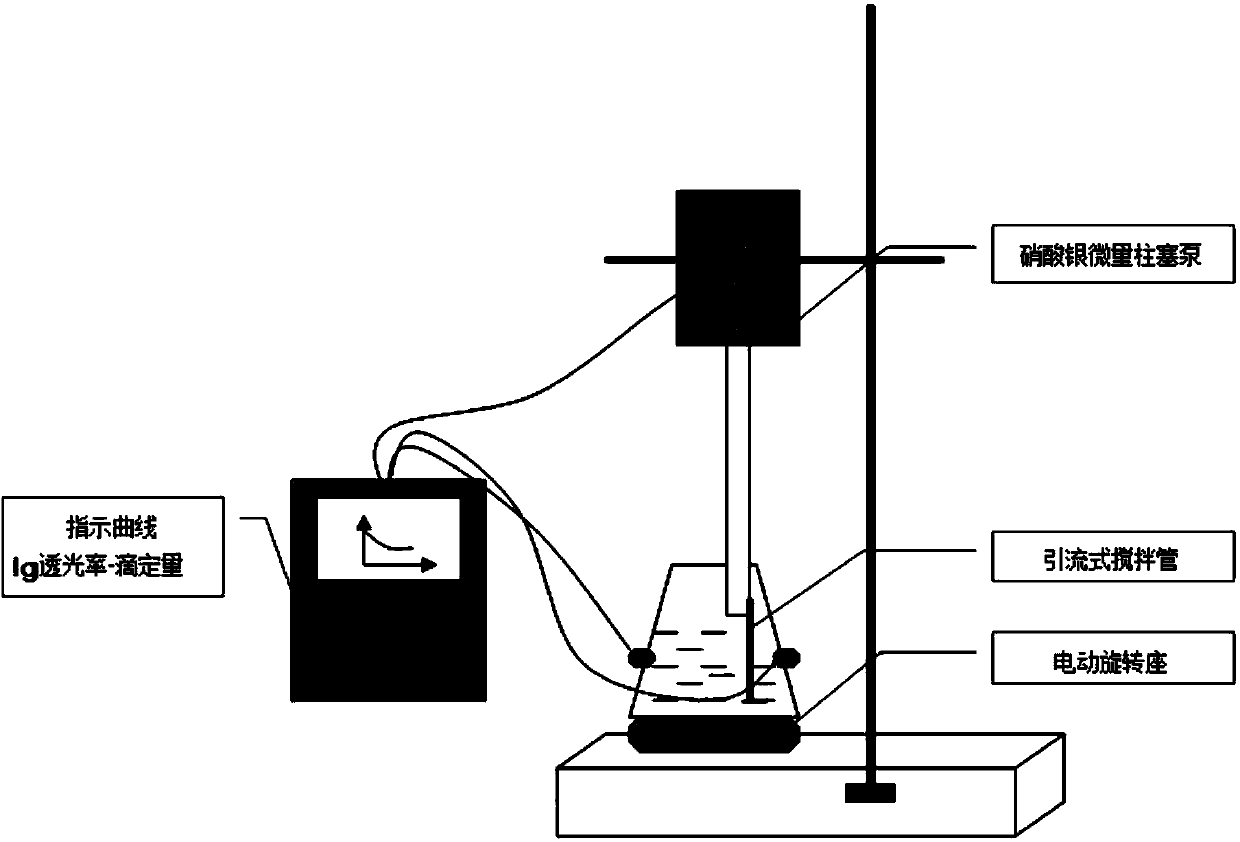

[0051] 3. Fix the micropump on the titration stand with a butterfly clip. And pour 0.05mol / l silver nitrate standard solution into the micropump.

[0052] 4. Place a 100ml beaker under the nozzle of the micropump, turn on the switch of the micropump, discharge the air from the lower part, and when the liquid level is aligned with a certain scale, turn off the switch immediately for use.

[0053] 5. Use a straight pipette and a suction ball to take an appropriate amount of filtered steam condensed water sample (10ml), and place it in an empty Erlenmeyer flask B.

[0054] 6. Add 2-3 drops of 1% phenolph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com