Changing-streamline adjusting method after polymer flooding

An adjustment method and polymer technology, which are applied in climate change adaptation, special data processing applications, instruments, etc., can solve problems such as lack of experience and no excessive well pattern adjustment in water drive units, and achieve the effect of reducing risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above and other objectives, features, and advantages of the present invention more obvious and understandable, the following examples are specially cited, in conjunction with the accompanying drawings, and are described in detail as follows.

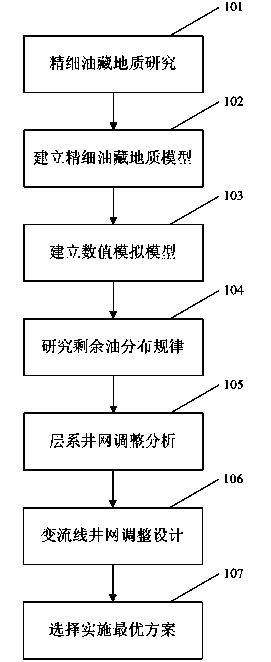

[0036] Such as figure 1 As shown, figure 1 It is a flowchart of a specific embodiment of the method for adjusting the streamline after polymer flooding of the present invention. This method considers the ultra-high water cut development period after polymer flooding where the reservoir is located, and also considers the long-term use of a regular, high-density well pattern.

[0037] In step 101, fine oil reservoir geology research, mainly studying stratigraphic correlation, structure, reservoir, sedimentary facies, oil-water system, temperature and pressure system. The flow proceeds to step 102.

[0038] In step 102, combined with the fine reservoir geology research, a fine reservoir three-dimensional geological mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com