High-flexibility anti-bending robot cable

A robot and cable technology, applied in the field of high-flexibility and bending-resistant robot cables, can solve the problems that the cables cannot be worn for a long time, the soft performance is not very good, and affect the company's economic benefits, and achieve excellent dynamic fatigue resistance, excellent environmental performance, The effect of uniform appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

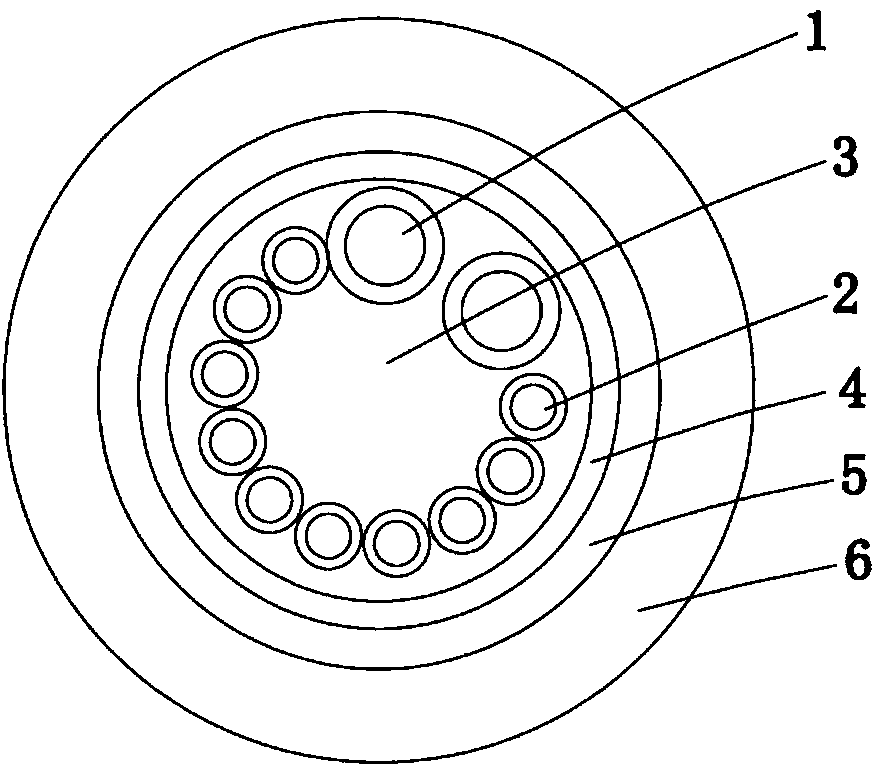

[0022] Example: Combined figure 1 , the high-flexibility and bending-resistant robot cable of this embodiment adopts the power system unit 1 and the control system unit 2 to twist into a cable core, and a cotton rope filling layer 3 is provided in the gap between the cable cores, and the cable core and the cotton rope filling layer are sequentially wrapped with Aluminum foil shielding layer 4, braided with tinned copper wire shielding layer 5, the outermost layer of the cable is extruded with a thermoplastic elastomer outer sheath 6; wherein, the power system unit 1 and the control system unit 2 are respectively made of conductors and extruded on the said It is composed of polyvinyl chloride insulation layer on the outer layer of the conductor.

[0023] figure 1 As shown, the control system unit 2 is composed of 2-10 wire cores twisted in pairs.

[0024] In the specific implementation, the conductors of the power system unit 1 and the control system unit 2 are bundled (-re-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com