A kind of forage grass and its processing method

A processing method and forage technology, which is applied in the agricultural field, can solve problems such as limiting the fermentation quality of forage silage, restricting the long-term development of animal husbandry, and poor quality of forage fermentation, achieving the effects of reducing the ratio, reducing the loss rate, and increasing the dry matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, the method for processing forage grass according to the present invention

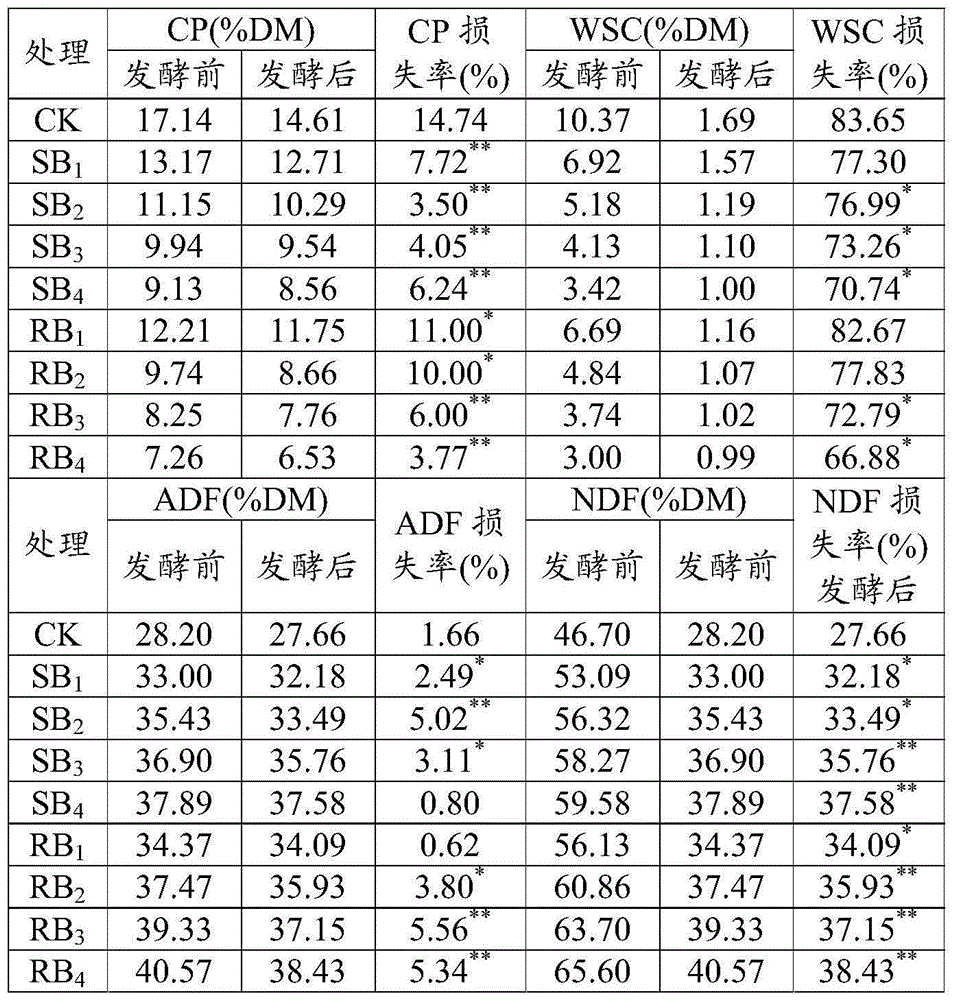

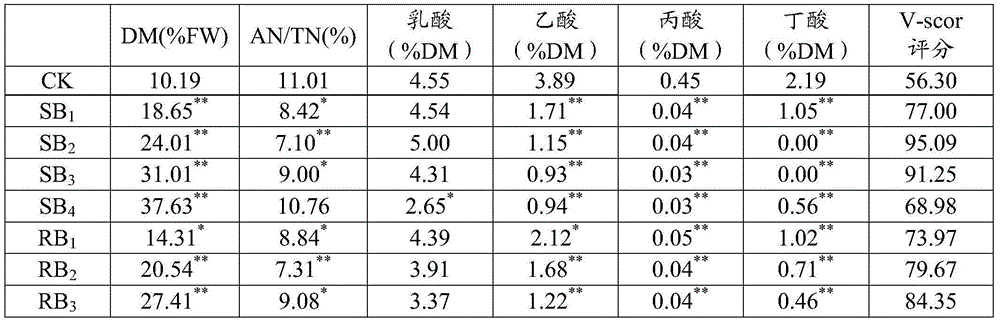

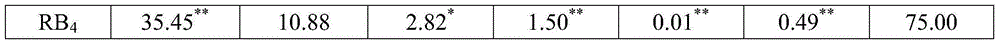

[0020] Cut the ryegrass multiflora at the booting stage of the first crop with a water content of 85%-90% into 2cm-3cm segments, and mix them with soybean stalks that are also cut into 2cm-3cm segments, and the forage: soybean stalk mass ratio is 6:4, fermented for 42 days at 20°C-25°C under airtight conditions.

Embodiment 2

[0021] Embodiment 2, the method for processing grass according to the present invention

[0022] Cut the ryegrass multiflora at the booting stage of the first crop with a water content of 85%-90% into 2cm-3cm segments, and mix them with soybean stalks that are also cut into 2cm-3cm segments, and the forage: soybean stalk mass ratio is 9:1, fermented for 42 days at 20°C-25°C under airtight conditions.

Embodiment 3

[0023] Embodiment 3, the method for processing grass according to the present invention

[0024] Cut the ryegrass multiflora at the booting stage of the first crop with a water content of 85%-90% into 2cm-3cm segments, and mix them with soybean stalks that are also cut into 2cm-3cm segments, and the forage: soybean stalk mass ratio is 8:2, fermented for 42 days at 20°C-25°C under airtight conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com