Fillet weld recognition device and welding control method thereof

A technology for identifying devices and control methods, applied in auxiliary devices, digital controls, welding equipment, etc., can solve problems such as low welding efficiency, cumbersome control process, and complex algorithms, so as to achieve convenient weld identification, accurate determination of welds, The Effect of Simplified Calculation Algorithm for Weld Seam Recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

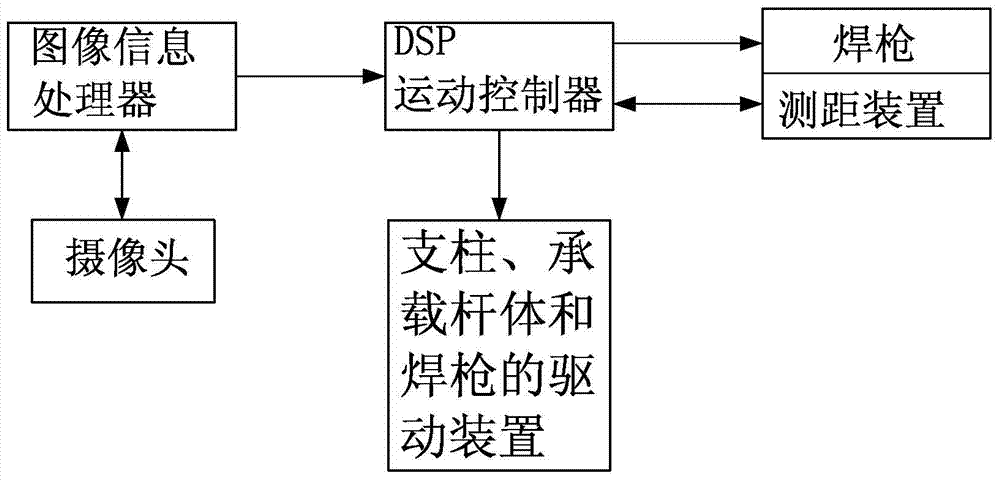

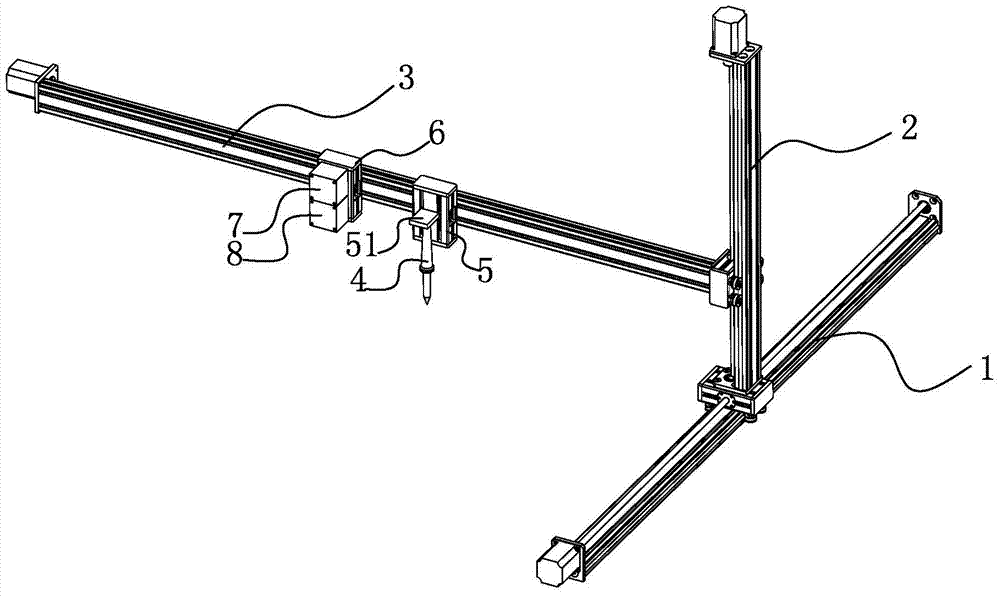

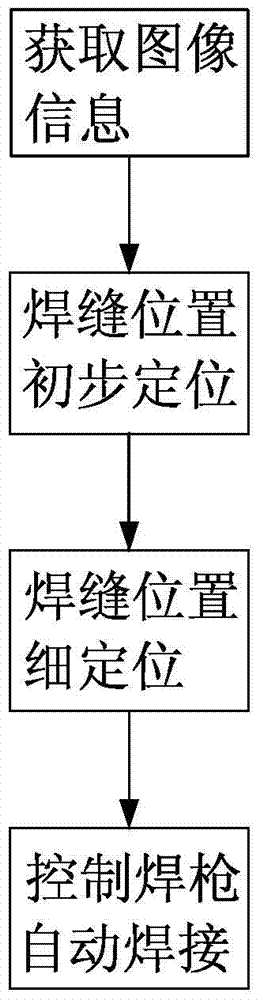

[0024] Such as Figure 1-2 As shown, a fillet weld recognition device consists of two parts, one is the image information acquisition and processing part including the image information processor and camera, and the other is the mechanical part with a frame as the cylinder , wherein the camera collects the image information of the weld and sends it to the image information processor, the image information processor communicates with a DSP motion controller, and the frame consists of a crossbar 1 as a base, a pillar 2 vertically slidably connected to the crossbar 1 and It consists of a bearing rod body 3 slidably connected to the pillar. The welding torch 4 is slidably connected to the bearing rod body 3. The distance measuring device is also slidably connected to the bearing rod body 3. The distance measuring device sends a weld distance signal to the DSP motion controller. The DSP motion controller sends control signals to the driving devices of the pillar 2 , the carrying ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com