A Welding Method Based on Valve Stress Dispersion

A technology of stress dispersion and welding method, which is applied in the direction of welding equipment, arc welding equipment, workpiece edge, etc., can solve problems such as failure, and achieve the effects of weakening stress concentration, reducing sharpness, and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

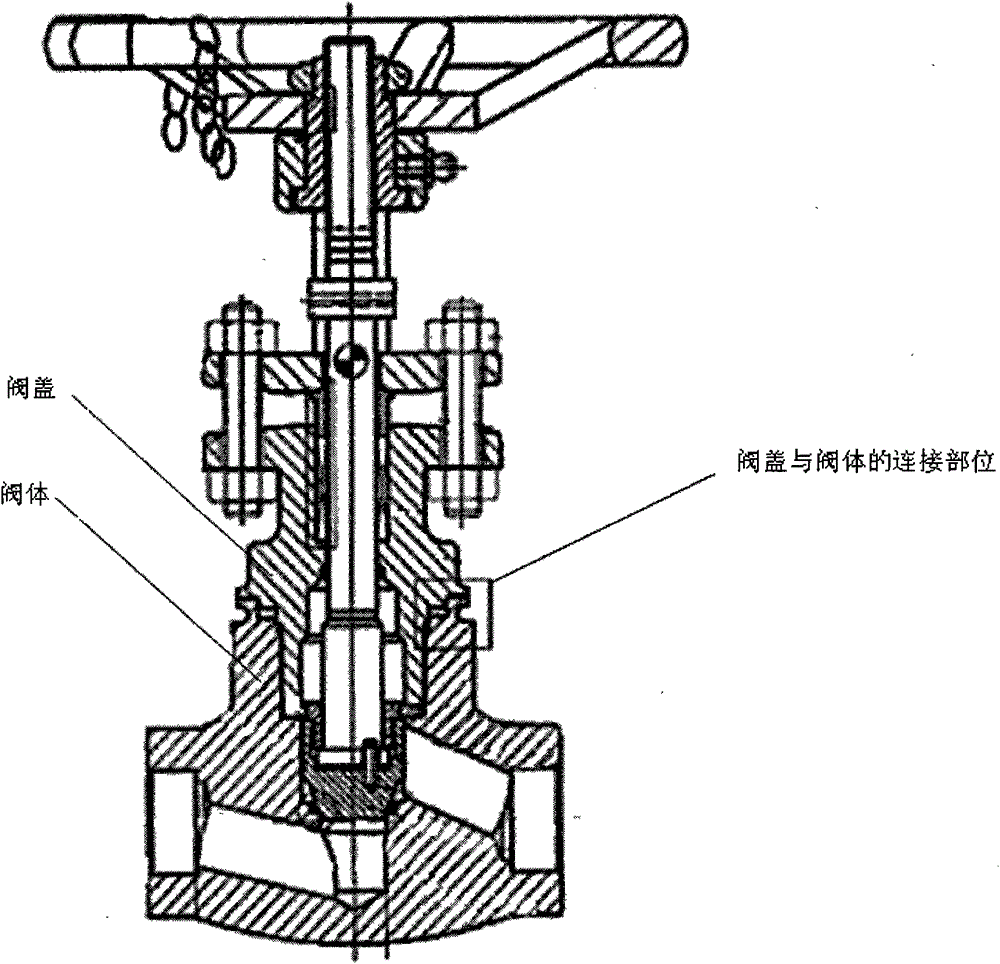

[0029] 1. The surface of the connecting part of the valve cover and the valve body is treated in the early stage, and the surface of the lip part of the valve cover and the valve body is polished with sandpaper or a grinding wheel to ensure that the connecting surface is smooth and clean, with good machining performance and welding environment;

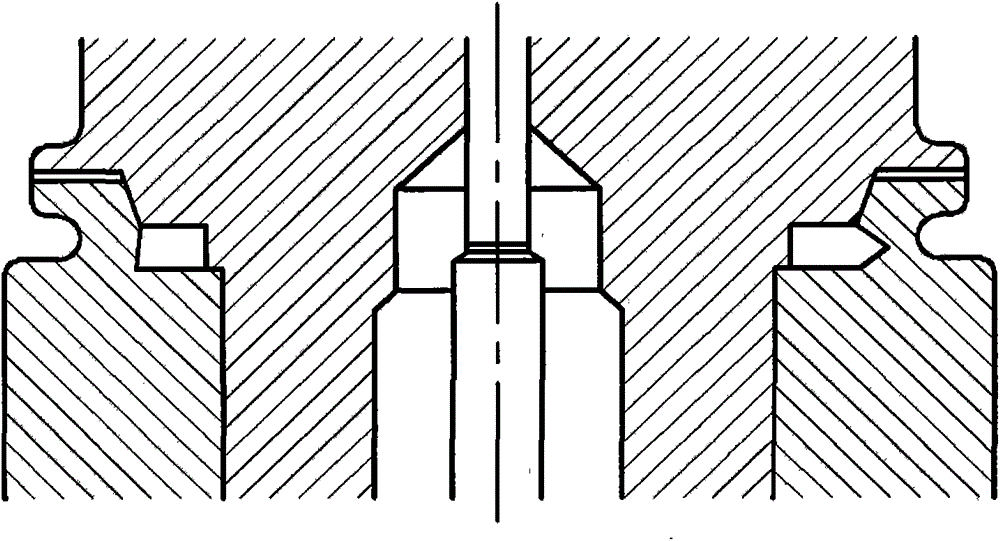

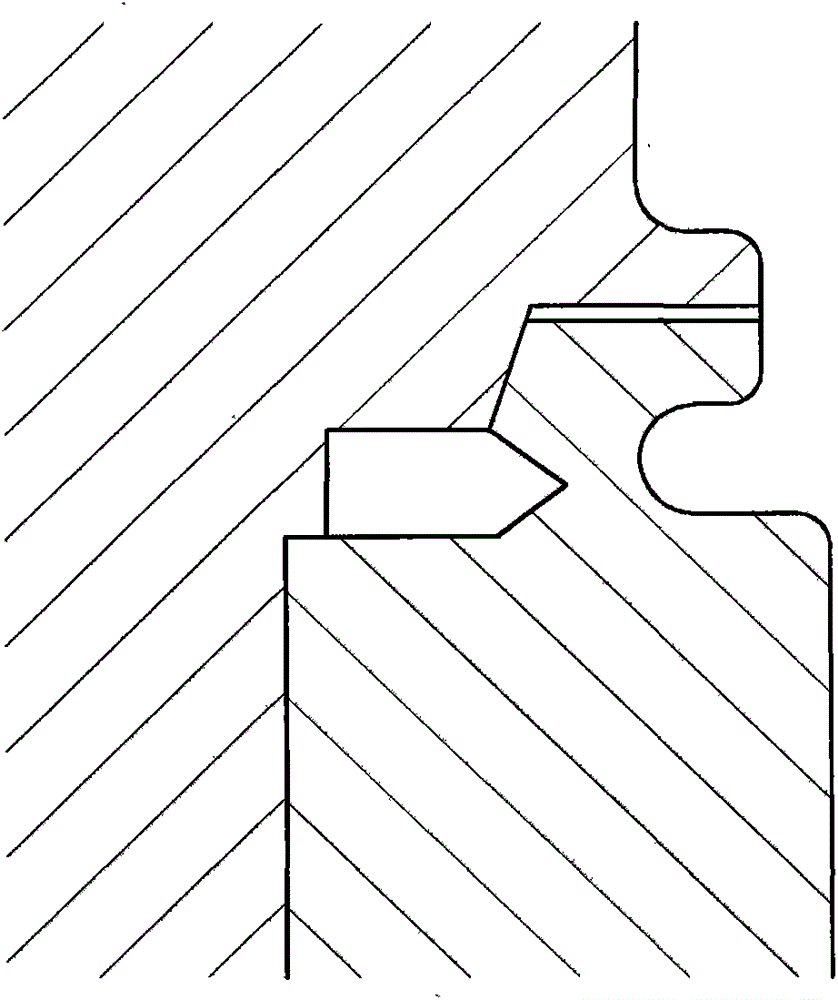

[0030] 2. Using the machining method of drilling, fix the valve cover and the valve body on the drilling machine, and use the drill bit to process a hemispherical opening of an appropriate size at the corresponding position of the connecting part. The diameter of the spherical opening is 2 ~ 3mm. The minimum distance between the spherical opening and the valve cover and the outer surface of the valve body is 1.5-3 mm. In the process of processing the spherical opening, the bonnet and the valve body are fixed with fixtures to avoid deformation of the bonnet and the valve body, minimize the residual stress of the bonnet and the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com