A production process of low-carbon gas-shielded welding wire

A production process, carbon gas technology, applied in metal material coating process, welding medium, manufacturing tools, etc., can solve the problems of reduced production efficiency, increased broken wire rate, uneven adhesion of lubricating carrier, etc., to achieve increased production efficiency , The broken wire rate is reduced, and the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

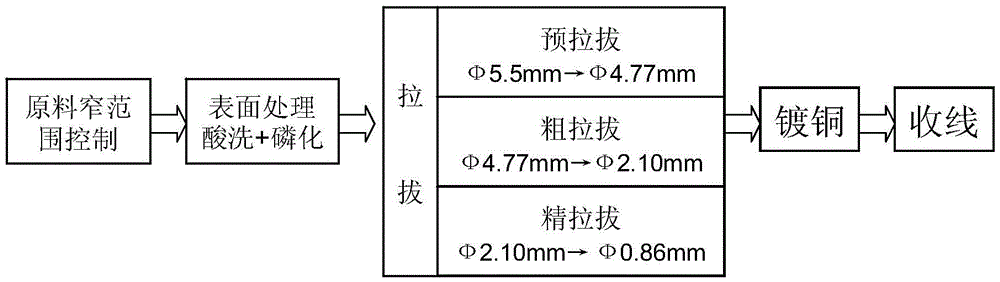

Method used

Image

Examples

Embodiment 1

[0020] Welding wire specification: φ1.6mm.

[0021] (1) raw material selection: the chemical composition is calculated as a percentage by C=0.09%, Si=0.95%, Mn=1.50%, P=0.013, S=0.005%, Ca=0.0012%; wire rod tensile strength 540MPa, Elongation ≥ 37%, area shrinkage ≥ 73%; size deviation 0.09mm.

[0022] (2) Surface treatment process: pickling process adopts automatic pickling equipment for pickling, the proportion of pickling solution is 10% of pre-washing hydrochloric acid concentration, 15% of washing matrix hydrochloric acid concentration, FeCl 2 200g / l, pickling time 20min. Rinse with high-pressure water immediately after pickling, water PH=6.8, water pressure=0.8Mpa; phosphating process adopts automatic phosphating equipment for surface treatment, the ratio of phosphating solution is Ta total acidity 78pt, Fa free acidity 11pt, phosphating The temperature is 73°C, and the phosphating time is 2 minutes.

[0023] (3) Drawing process: pre-drawing, double-drum single-pass d...

Embodiment 2

[0026] Welding wire specification: φ1.20mm.

[0027] (1) Raw material selection: the chemical composition is calculated in percentage as C=0.08%, Si=0.90%, Mn=1.55%, P=0.014, S=0.005%, Ca=0.0010%; wire rod tensile strength 532MPa, Elongation ≥ 36.5%, area shrinkage ≥ 75%; size deviation 0.07mm.

[0028] (2) Surface treatment process: pickling process adopts automatic pickling equipment for pickling, the proportion of pickling solution is 10% of pre-washing hydrochloric acid concentration, 17% of washing matrix hydrochloric acid concentration, FeCl 2 ≤190g / l, pickling time 19min, wash with high-pressure water immediately after pickling, water PH=6.8, water pressure=0.8Mpa;

[0029]The phosphating process adopts automatic phosphating equipment for surface treatment. The ratio of phosphating solution is 76pt of total acidity of Ta, 10pt of free acidity of Fa, phosphating temperature of 76℃, and phosphating time of 2min.

[0030] (3) Drawing process: pre-drawing, double-drum sin...

Embodiment 3

[0033] Welding wire specification: φ0.80mm.

[0034] (1) Raw material selection: the chemical composition is calculated in percentage as C=0.06%, Si=0.80%, Mn=1.43%, P=0.012, S=0.004%, Ca=0.0012%; wire rod tensile strength 520MPa, Elongation ≥ 38.0%, area shrinkage ≥ 78%; size deviation ± 0.10mm.

[0035] (2) Surface treatment process: pickling process adopts automatic pickling equipment for pickling, the proportion of pickling solution is 8% of pre-washing hydrochloric acid concentration, 20% of washing matrix hydrochloric acid concentration, FeCl 2 ≤210g / l, pickling time 21min, rinse with high-pressure water immediately after pickling, water PH=6.8, water pressure=0.8Mpa; phosphating process adopts automatic phosphating equipment for surface treatment, the ratio of phosphating solution is total Ta The acidity is 78pt, the free acidity of Fa is 10pt, the phosphating temperature is 75℃, and the phosphating time is 3min.

[0036] (3) Drawing process: pre-drawing, φ5.5mm~φ4.70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com