Polishing pad and production method thereof

A technology of polishing pad and polyurethane vinyl, which is applied in the field of sapphire polishing, can solve the problems of difficult stirring operation, single manufacturer, scattered flying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

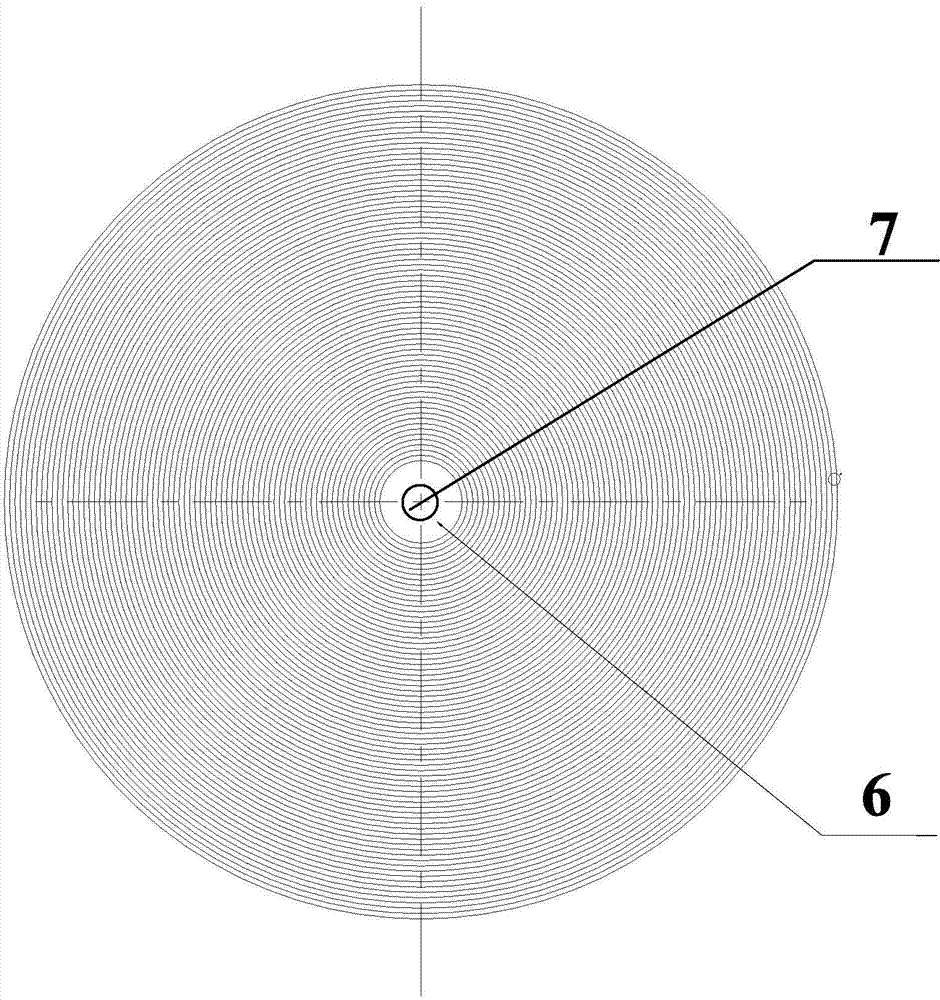

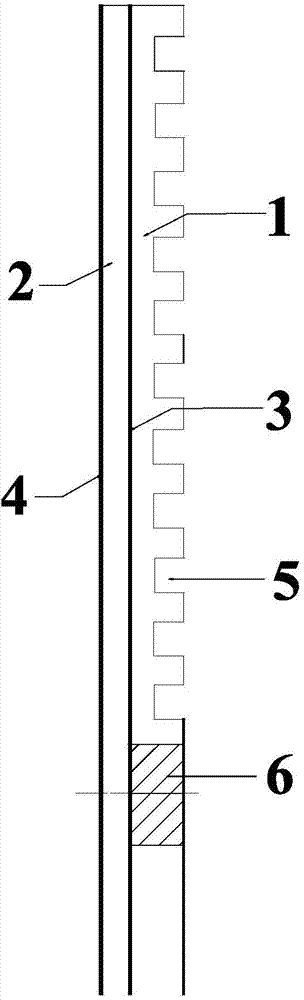

Image

Examples

preparation example Construction

[0043] A preparation method of a polishing pad includes the following steps:

[0044] 1) The prepolymer reactant is heated to 75°C, the MOCA is heated to 115°C, and then gel is performed at a temperature of 75°C to 115°C. The gel time is about 5 to 15 minutes, wherein the prepolymer The weight ratio of the body reactant to the MOCA is 3.58:1;

[0045] 2) Add the ultra-short polyester fiber or ultra-short aramid fiber with a weight percentage of 1% to 8% to the prepolymer reactant, and use a stirring box to mix the prepolymer reactant with the prepolymer at a speed of 1500rpm to 3500rpm. MOCA is thoroughly stirred and mixed to obtain mixture A;

[0046] 3) Put the mixture A in a centrifuge at 92°C to 110°C for high temperature gelation, and gel for 30 to 90 minutes to obtain a gelled polyurethane sheet;

[0047] 4) Transfer the gelled polyurethane sheet obtained in step 3) to a vulcanization oven, and vulcanize at a temperature of 100°C to 120°C for 10 to 17 hours to obtain a cured po...

Embodiment 1

[0053] Example 1 Test data and results of oxide layer polishing

[0054] 1. Polishing mechanical parameter setting

[0055]

[0056]

[0057] Polishing result:

[0058]

[0059] Polishing rate and polishing flat rate:

[0060]

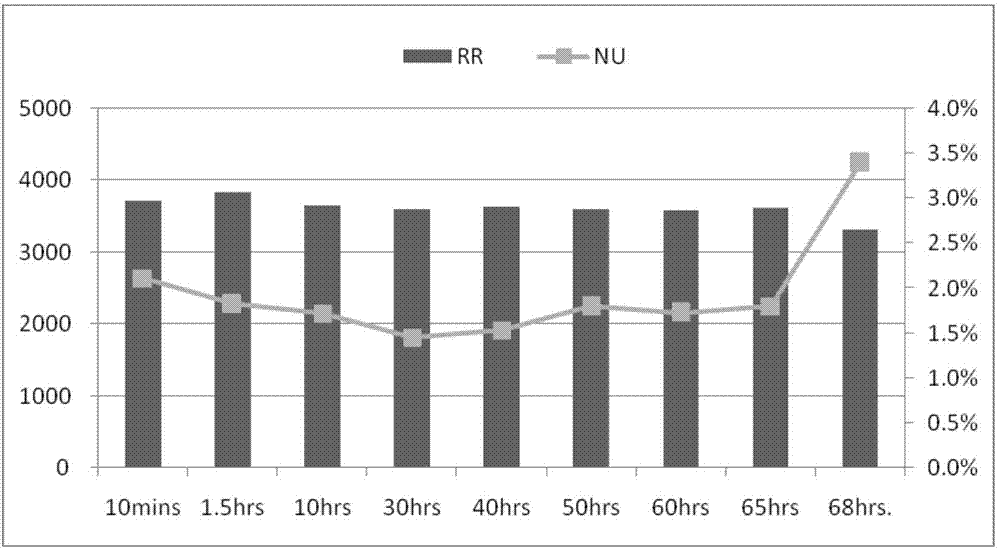

[0061] From the above test results and image 3 It can be seen that the overall polishing rate of polyurethane polishing pads with polyester added can be improved by fine-tuning the polishing pressure, and the polishing flatness rate is very stable and maintained at about 2%. This flatness rate is relative to the flat rate value of less than or equal to 7% generally recognized in the market. There is a substantial reduction. In chemical mechanical polishing, the lower the global polishing flat rate, the better the overall polishing effect and the higher the yield of the chip.

Embodiment 2

[0062] Example 2 Test data and results of polishing on the metal layer

[0063] Polishing result:

[0064]

[0065]

[0066] Polishing rate and polishing flat rate:

[0067]

[0068] From the above test results and Figure 4 It can be seen that no matter how the polishing test parameters are adjusted, the polishing rate increases or decreases as the polishing parameters change. Polyurethane polishing pads added with 0.5% to 7% polyester fiber powder always show excellent and very stable global flatness. Rate (NU%). And the polishing life is greatly increased.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com