Step-type reconstituted bamboo (timber) production line equipment

A production line equipment and recombined bamboo technology, applied in wood processing appliances, household components, flat products, etc., can solve the problems of high labor intensity of workers, unstable material quality, low degree of automation, etc., to expand the application field and stabilize product quality , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with the best embodiment 。

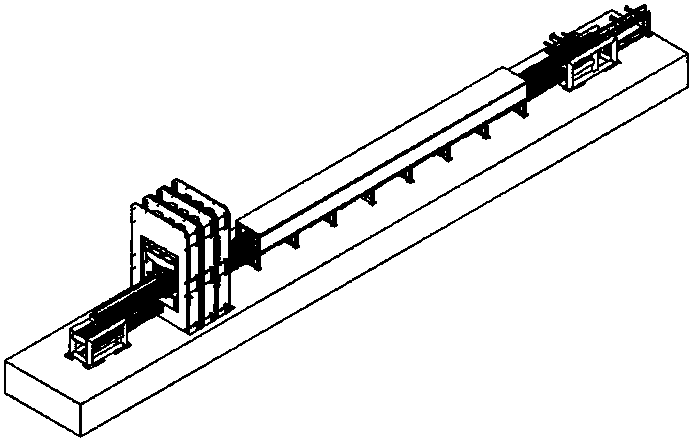

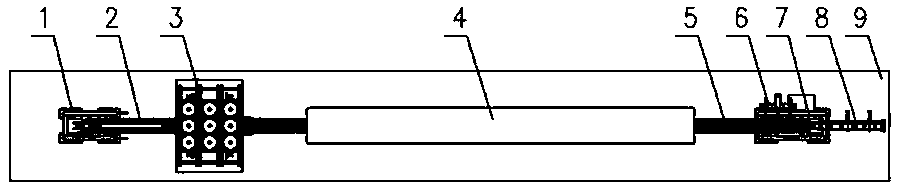

[0015] Such as Figure 1-2 As shown, a step-by-step recombined bamboo production line equipment includes an equipment base 9, and the base base 9 is provided with a feeder frame assembly 1, a feeding auxiliary transportation device 2, a molding machine 3, a curing channel equipment 4, and a mold Chain assembly 5, online withdrawal device 6, discharge machine frame assembly 7, and unloading device 8; the role of feeder frame assembly 1 is to transport materials to the production line; feeding auxiliary transport device 2 is to transport materials into the molding machine 3; the function of the molding machine 3 is to shape the material; the function of the curing channel equipment 4 is to heat and cure the formed material; the function of the mold chain assembly 5 is to transport the material assembly to the online withdrawal device 6; The function of the online cancellation device (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com