High-strength aluminum alloy prepainted sheet strip for vertical lockrand roof tiles and production method thereof

A technology of standing seam and production method, which is applied in the field of aluminum alloy manufacturing, can solve the problems of complex production process, limited material characteristics, high production cost, etc., and achieve the effect of improving corrosion resistance, unique alloy composition, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

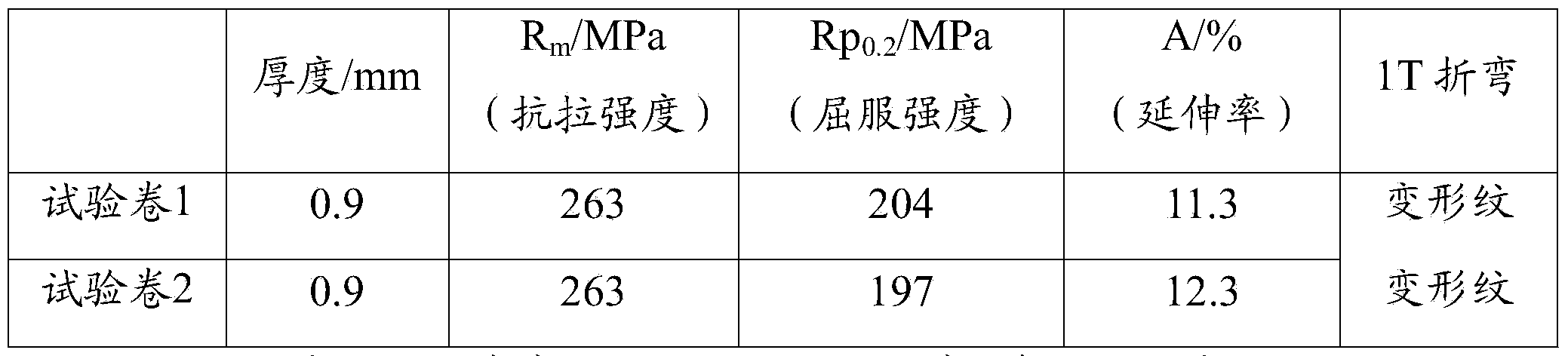

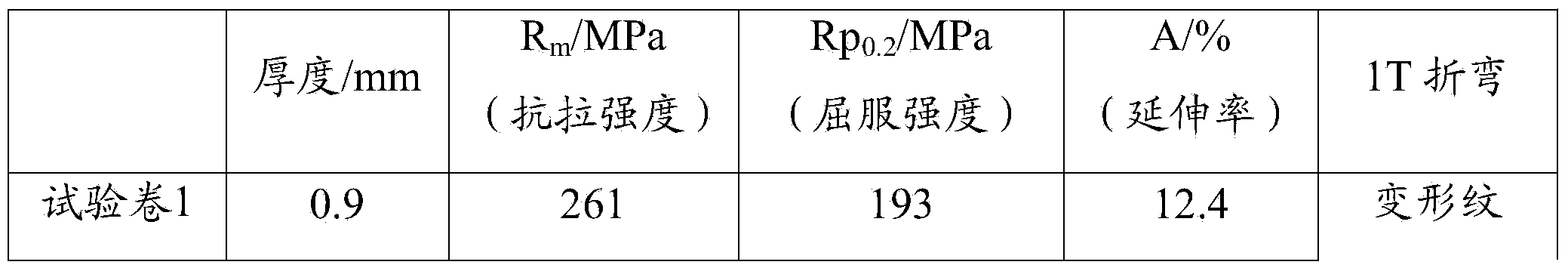

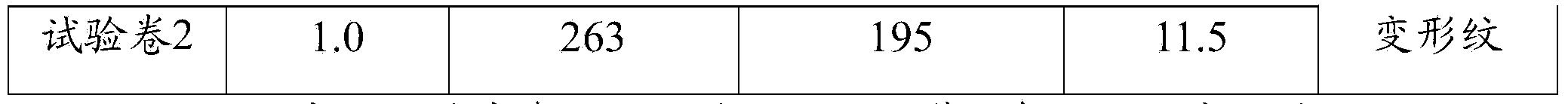

Examples

Embodiment 1

[0024] The production method of the high-strength aluminum alloy color-coated plate strip (AA02 alloy color aluminum plate) for standing seam roof tiles described in this embodiment, the production process includes: melting and casting → sawing → milling → heating → hot continuous rolling → cold Continuous rolling→finished product annealing→edge trimming and leveling→coating.

[0025] The specific process parameters are as follows:

[0026] (1) Melting and casting: the mass percentage of the chemical composition of the ingot after melting and casting is (other impurity elements individually ≤0.05%, such as Zn, and the total of other impurity elements ≤0.15%):

[0027] Si

Fe

Cu

mn

Mg

Ti

Cr

Zn

Al

0.16%

0.35%

0.11%

0.55%

2.40%

0.02%

0.06%

0.02%

margin

[0028] The melting temperature is 730-750°C, the refining temperature is 740-750°C, the casting temperature is 680-695°C, and the casting spee...

Embodiment 2

[0038] The production method of the high-strength aluminum alloy color-coated plate strip (AA02 alloy color aluminum plate) for standing seam roof tiles described in this embodiment, the production process includes: melting and casting → sawing → milling → heating → hot continuous rolling → cold Continuous rolling→finished product annealing→edge trimming and leveling→coating.

[0039] The specific process parameters are as follows:

[0040] (1) Melting and casting: the mass percentage of the chemical composition of the ingot after melting and casting is (single ≤0.05% of other impurity elements, ≤0.15% of other impurity elements in total):

[0041] Si

Fe

Cu

mn

Mg

Ti

Cr

Zn

Al

0.12%

0.35%

0.07%

0.45%

2.56%

0.02%

0.05%

0.02%

margin

[0042] The melting temperature is 725-740°C, the refining temperature is 735-745°C, the casting temperature is 680-700°C, and the casting speed is 55mm / min;

[0...

Embodiment 3

[0053] The production method of the high-strength aluminum alloy color-coated plate strip (AA02 alloy color aluminum plate) for standing seam roof tiles described in this embodiment, the production process includes: melting and casting → sawing → milling → heating → hot continuous rolling → cold Continuous rolling→finished product annealing→edge trimming and leveling→coating.

[0054] The specific process parameters are as follows:

[0055] (1) Melting and casting: the mass percentage of the chemical composition of the ingot after melting and casting is (single ≤0.05% of other impurity elements, ≤0.15% of other impurity elements in total):

[0056] Si

Fe

Cu

mn

Mg

Ti

Cr

Zn

Al

0.09%

0.31%

0.13%

0.42%

2.73%

0.02%

0.05%

0.02%

margin

[0057] The melting temperature is 730-745°C, the refining temperature is 740-750°C, the casting temperature is 682-695°C, and the casting speed is 65mm / min;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com