Combined threaded tube water fire tube boiler

A threaded tube and combined technology, applied in fire tube type steam boilers, water tube type steam boilers, boiler smoke tubes/fire tubes, etc., can solve the bulging at the bottom of the drum, the scaling and bursting of the water wall, and the cracks in the front tube plate. and other problems, to achieve the effect of reducing the original dust concentration, solving the water-cooled wall burst pipe, and improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

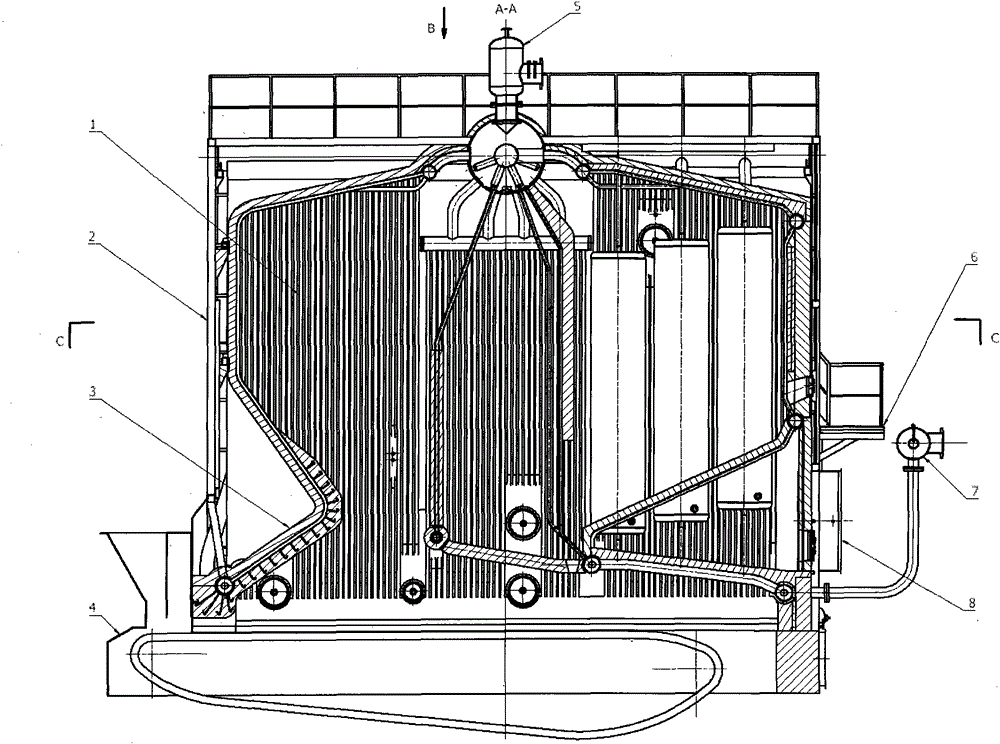

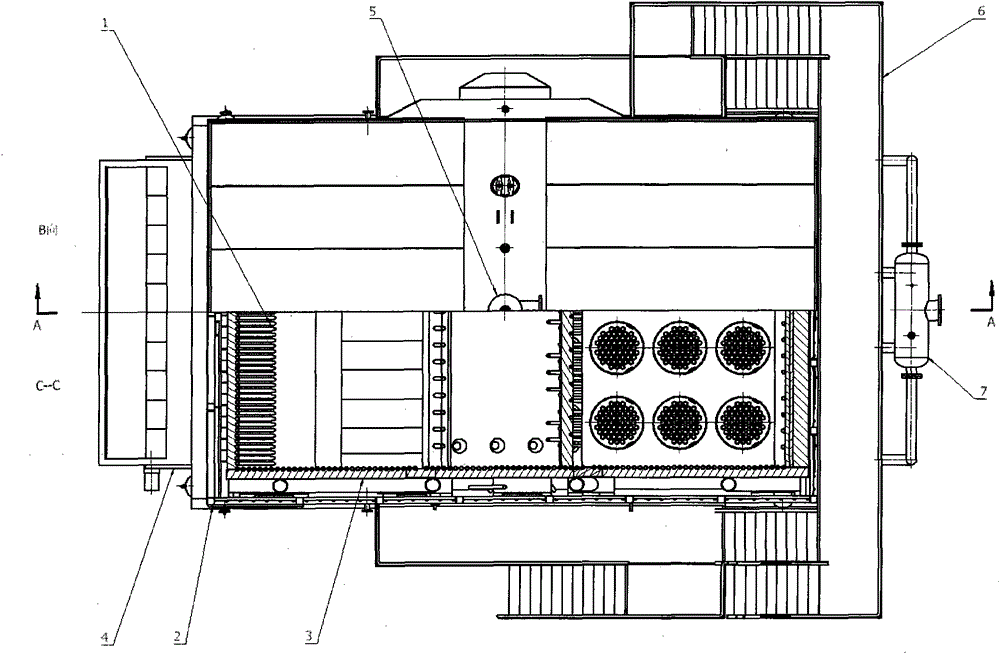

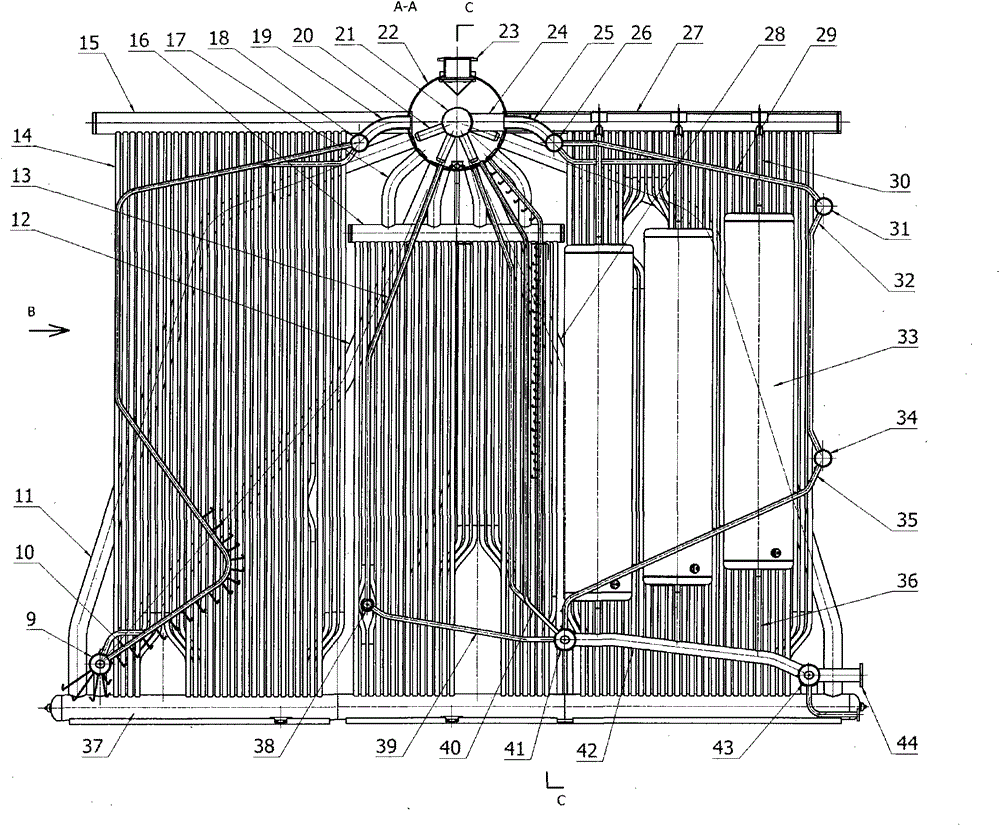

[0018] The overall structure of the boiler of the present invention includes a body (1), a steel frame guard plate (2), a furnace wall insulation (3), a chain grate (4), a gas collecting tank (5), a platform escalator guardrail (6), a return water Distribution header (7), boiler flue gas outlet (8) and other components. After the boiler is installed, it also involves equipment such as pipelines, flue gas ducts, dust collectors and desulfurizers, induced draft fans, coal loading and slagging machines, valves and instruments, and control circuits.

[0019] The boiler body (1) includes components such as a drum, left and right water-cooled wall tube assemblies, a front arch tube assembly, a rear arch tube assembly, and a combined threaded pipe. A horizontally arranged drum (22) is arranged on the upper part of the boiler body (1), and the drum (22) and other components form connections of various water circulation circuits. A water diversion conduit (21) is arranged at the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com