Concentrating type solar heat collecting and crude oil heating system

A solar heat collection and concentrating technology, applied in the field of solar energy applications, can solve problems such as difficulty in meeting medium and high temperature heat consumption, low solar energy utilization rate, and low heat collection temperature, so as to increase solar energy density, buffer pressure fluctuations, The effect of smooth operation of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

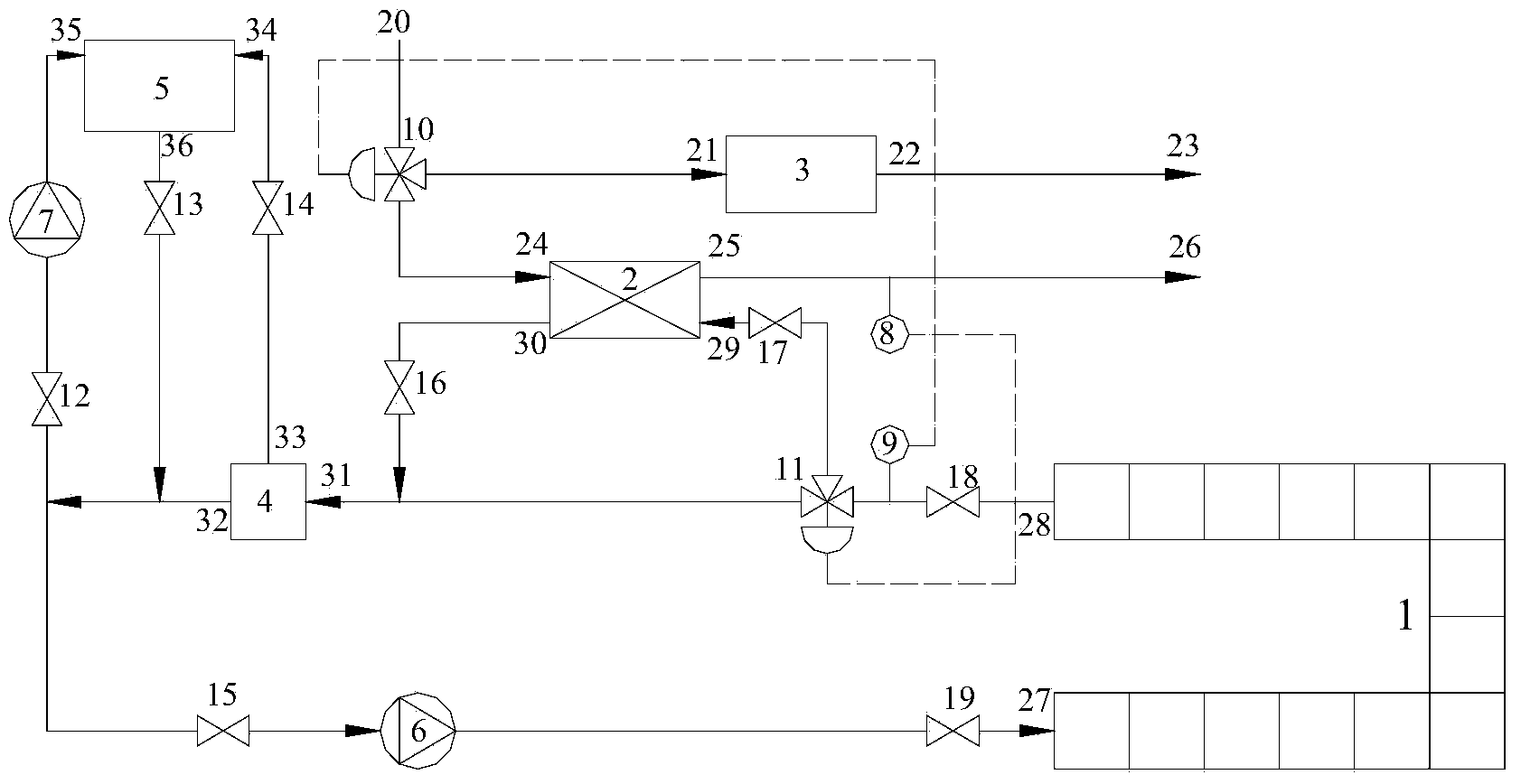

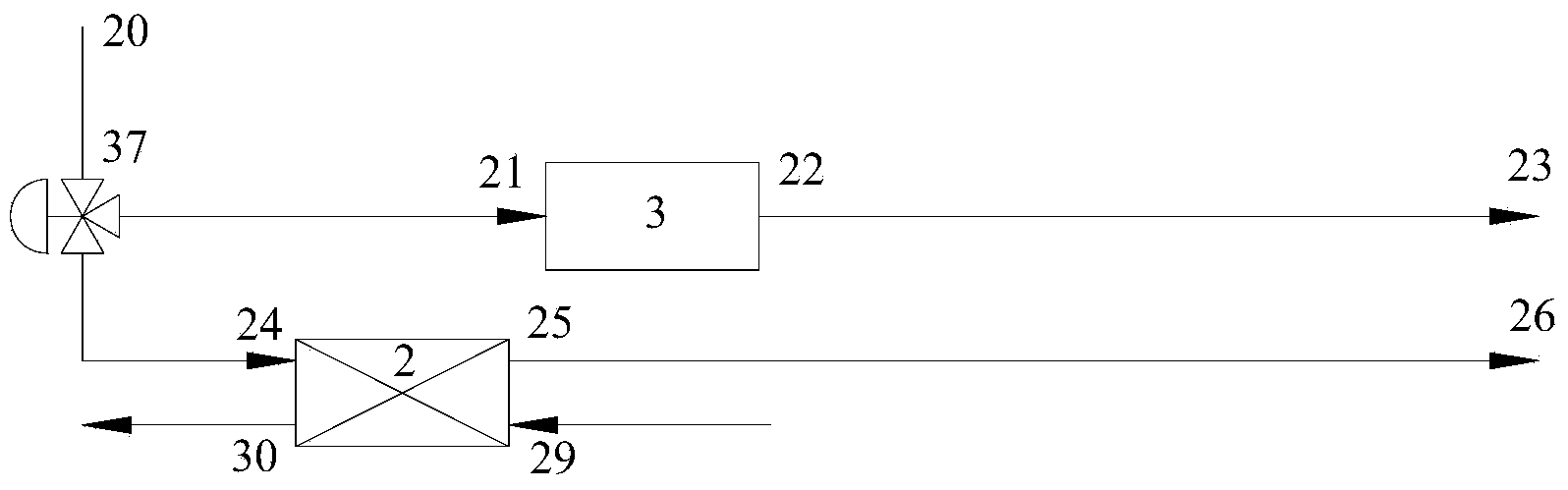

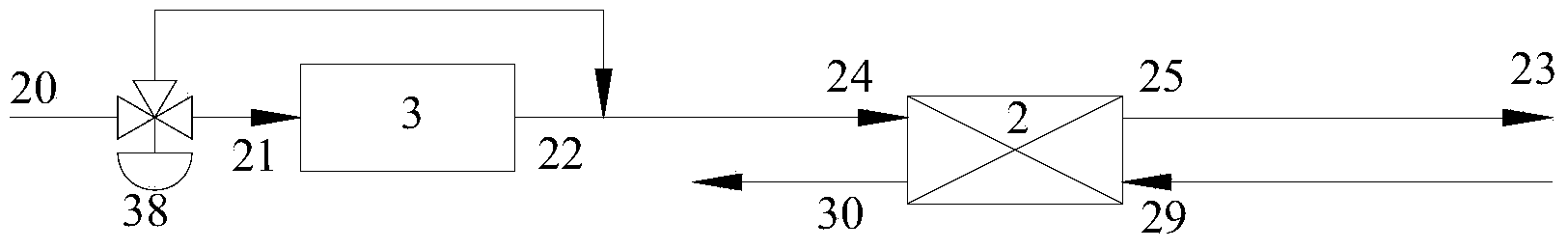

[0033] A concentrating solar heat collection and heating crude oil system, which includes a water bath jacket furnace, a heat exchanger, a buffer tank, an oil replenishment tank, a solar heat collector, a temperature control device, a circulation pump and an oil replenishment pump; it is characterized in that the crude oil The inlet 20 and the interface I of the electric three-way valve I10 are connected by a pipeline, the crude oil input end 21 of the water-bath jacket furnace 3 and the interface II of the electric three-way valve I10 are connected by a pipeline, the crude oil output end 22 of the water-bath jacket furnace 3 is connected to the crude oil The outlet 23 is connected by a pipeline, the crude oil input end 24 of the heat exchanger 2 is connected with the interface III of the electric three-way valve I10 by a pipeline, the crude oil output end 25 of the heat exchanger 2 and the crude oil outlet 26 are connected by a pipeline, the heat exchanger 2 The heat transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com