Multi-kind and small-quantity part production process capability index determining method based on features

A process capability index and multi-variety technology, applied in digital control, electrical program control, comprehensive factory control, etc., can solve problems such as difficulty in accurately calculating process capability index and insufficient sample size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

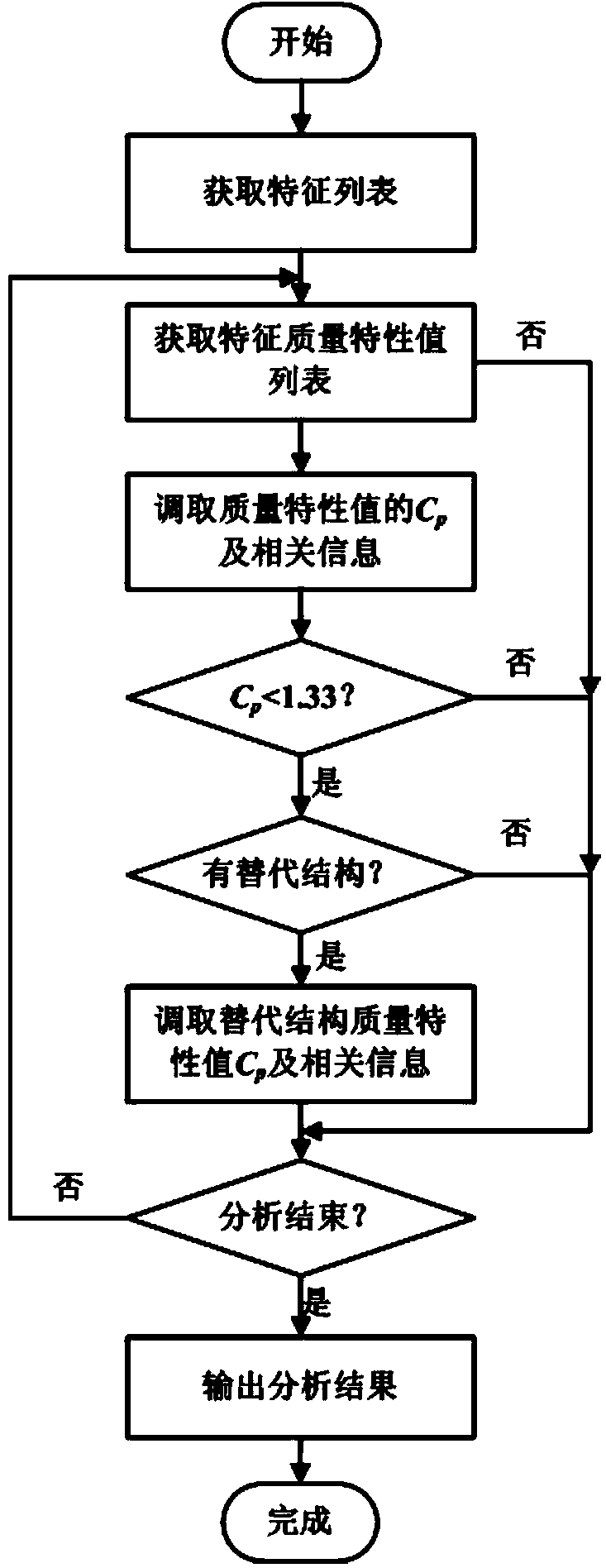

[0065] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0066] like Figure 1-3 shown.

[0067] A feature-based method for determining the process capability index of multi-variety and small-batch production parts, which includes the following steps:

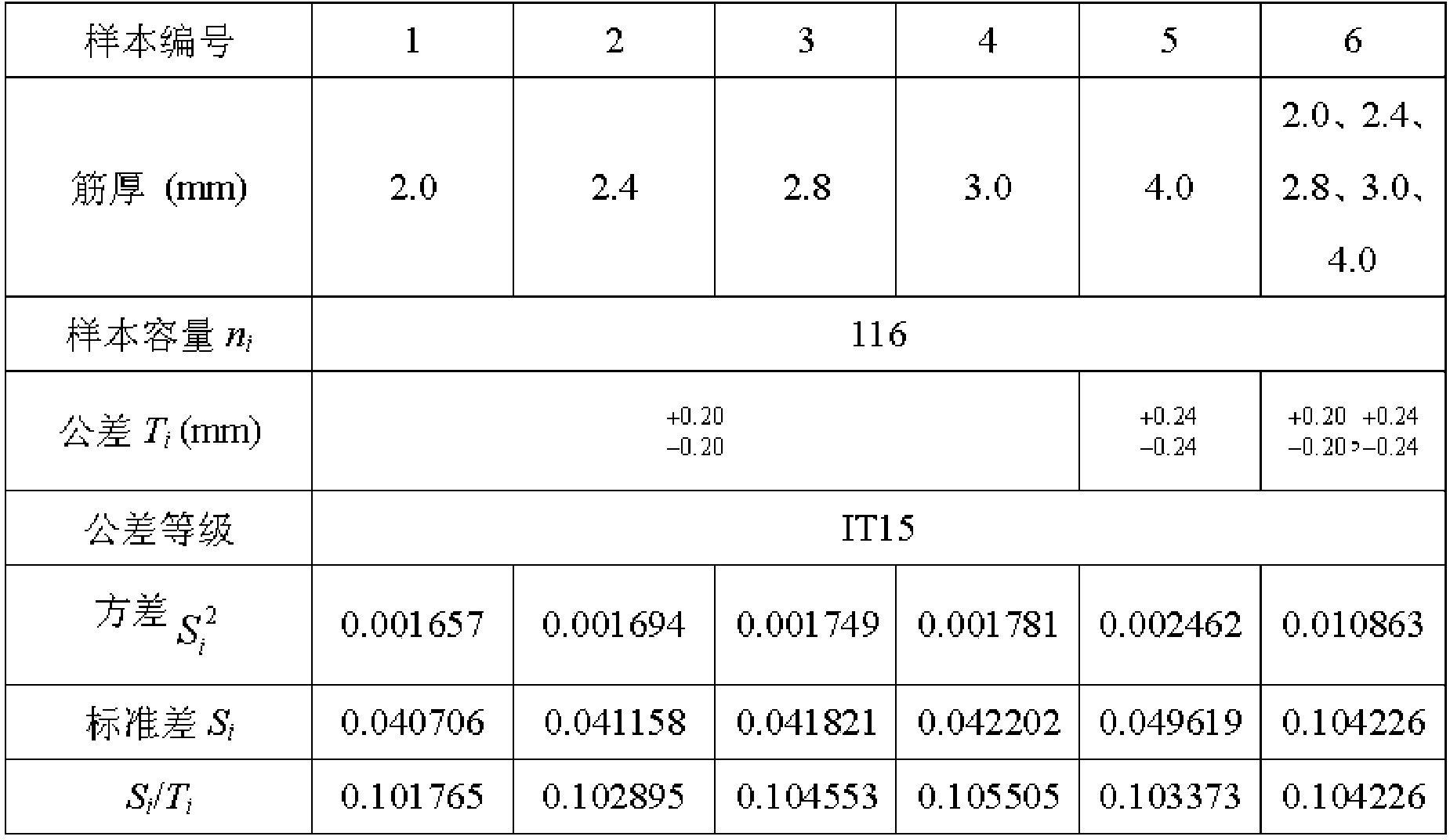

[0068] Step 1. Establish processing feature samples, define the quality characteristic values of processing features with different sizes but the same processing technology and tolerance level and the ratio of standard deviation to tolerance as the same processing feature sample, thereby expanding the sample capacity;

[0069] The steps to establish processing feature samples are as follows:

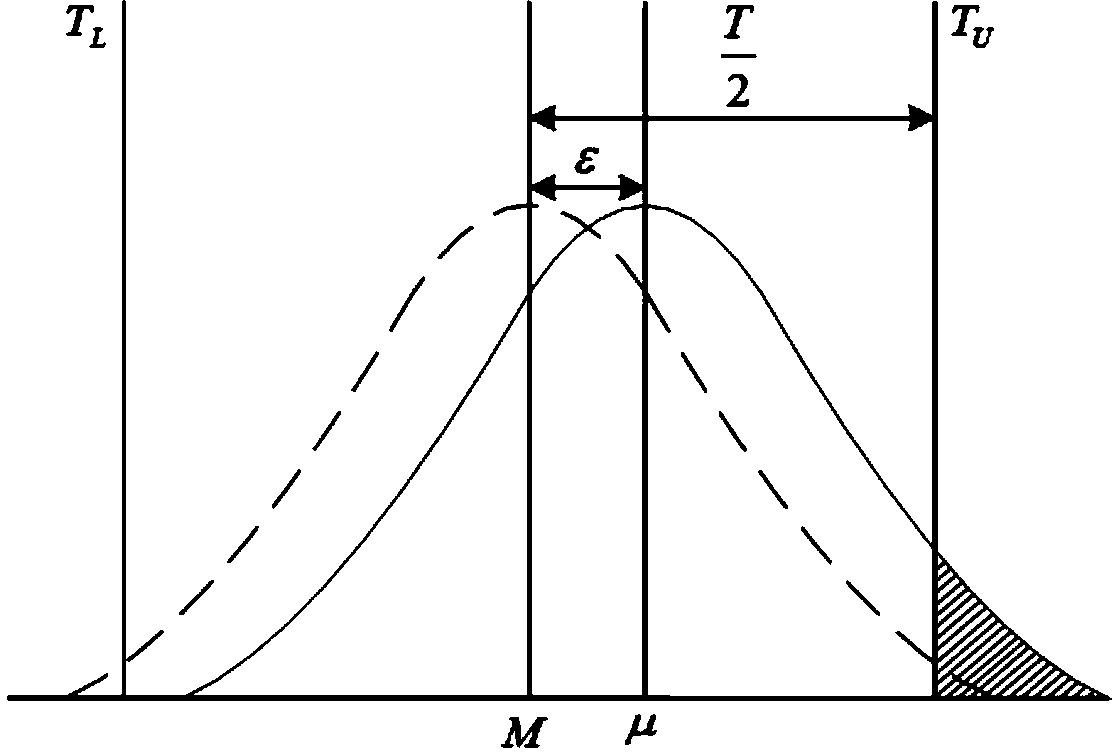

[0070] 1. Select a certain quality characteristic value of the processing feature, such as the rib thickness of the rib feature, the wall thickness of the wall feature, the aperture diameter and the hole depth of the hole feature, etc. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com