Bonded permanent magnet and production method thereof

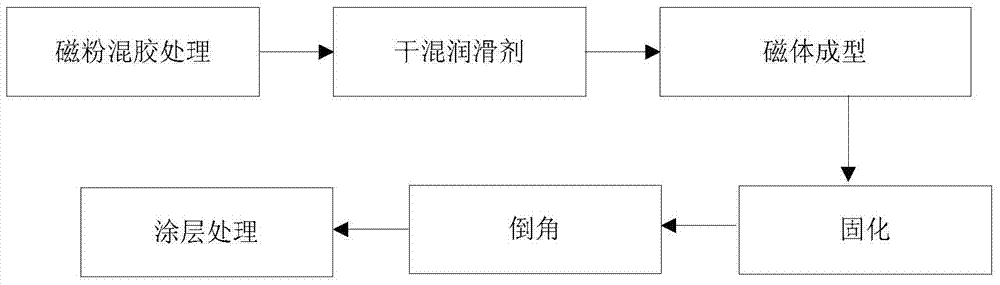

A technology of bonding magnets and magnetic powders, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of difficult demoulding, large magnet demoulding force, uneven distribution of lubricants, etc., to reduce magnet stripping Mold force, increased binding force, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

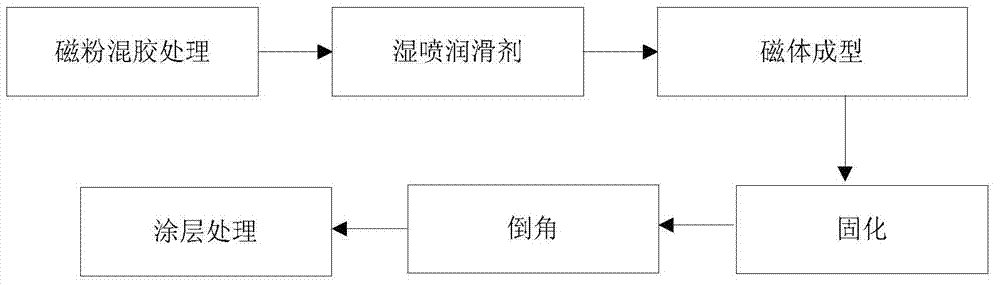

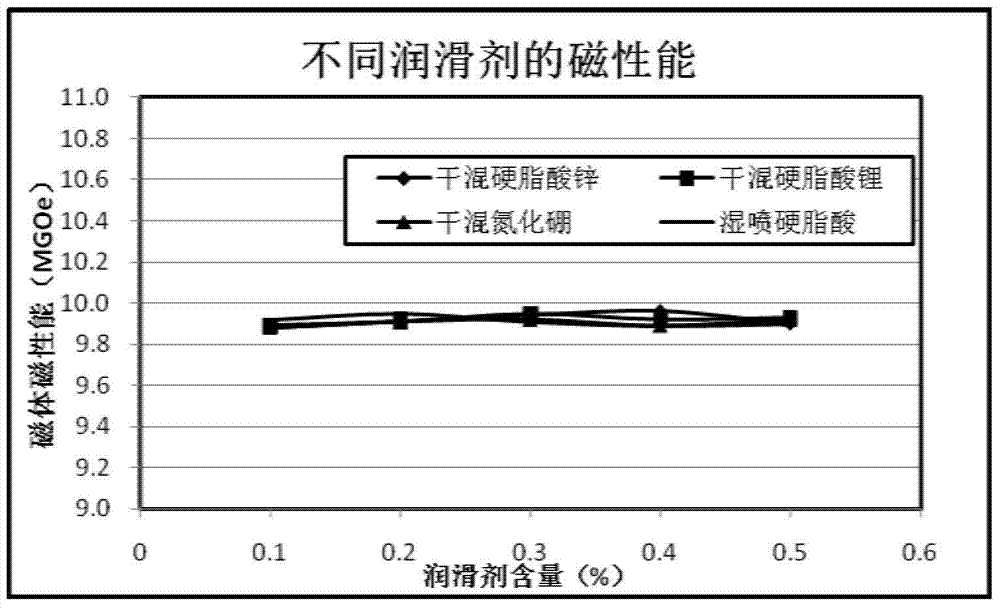

[0025] In order to solve the problems in the prior art that the lubricant is unevenly distributed in the bonded magnetic powder and the release force of the final bonded magnet is relatively large and the release is difficult, the present invention provides a preparation method of the bonded magnet, such as figure 2 As shown, the following steps are included: S1, mixing rare earth magnetic powder and thermosetting epoxy resin to obtain rubber mixing powder; S2, wet mixing lubricant and rubber mixing powder, and drying to obtain rare earth bonded magnetic powder; and S3, mixing rare earth magnetic powder The bonded magnetic powder is molded to obtain a rare earth bonded magnet.

[0026] When mixing rare earth magnetic powder mixed with thermosetting epoxy resin and lubricant, the wet mixing method is used instead of the current dry mixing lubricant method. Finally, a uniform lubricant coating film is formed on the surface of the mixed powder, thereby increasing Improve the bin...

Embodiment 1

[0038] 1) Take 135g of bisphenol-a epoxy resin (provided by Huanqi Chemical (Guangdong) Co., Ltd., model NPES902), and dissolve bisphenol-a epoxy resin in acetone (according to bisphenol-a epoxy resin and The mass ratio of acetone is mixed at 1:10) to obtain the dissolved bisphenol A epoxy resin.

[0039] 2) Mix the bisphenol A-type epoxy resin dissolved in step 1) with NdFeB magnetic powder (model MQP-15-9HD) under vacuum conditions to obtain mixed rubber powder; dissolve the lubricant stearic acid into In absolute ethanol (by weight, M 硬脂酸 :M 乙醇 =1:10), to obtain stearic acid ethanol solution. The stearic acid ethanol solution and the rubber compound powder are mixed in a mixing bucket, and then placed at room temperature to evaporate and dry the ethanol to obtain a bonded magnetic powder. Among them, the weight ratio of NdFeB magnetic powder, bisphenol A type epoxy resin and stearic acid is 95:4.5:0.5.

[0040] The operation method of Example 1 was repeated three times,...

Embodiment 2

[0042] The operation steps and methods are the same as in Example 1, except that the ethanol stearic acid liquid and the rubber mixing powder are not mixed directly, but the ethanol stearic acid liquid and the rubber mixing powder are sprayed and mixed by mixing equipment . The specific steps are: put the mixed rubber powder in the LDH-03 coulter mixer, start the heating device of the coulter mixer to heat the mixed rubber powder to 40°C, rotate at a speed of circle / 7s, and evacuate to 100pa , start the spraying device, the spraying pressure is 0.3MPa, put the stearic acid ethanol liquid in the spraying device, and spray the stearic acid ethanol liquid on the surface of the rubber mixture under vacuum (vacuum degree is less than 100pa) to obtain the sticky Junction magnetic powder.

[0043] The operation method of Example 2 was repeated three times, which were respectively recorded as Examples 2b-2d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com