Device for coating electrically conductive wires

A wire and coating technology, which is applied to the surface coating liquid device, conductor/cable insulation, coating, etc., can solve the problem of insufficient connection quality, achieve less space, low energy consumption, high The effect on process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

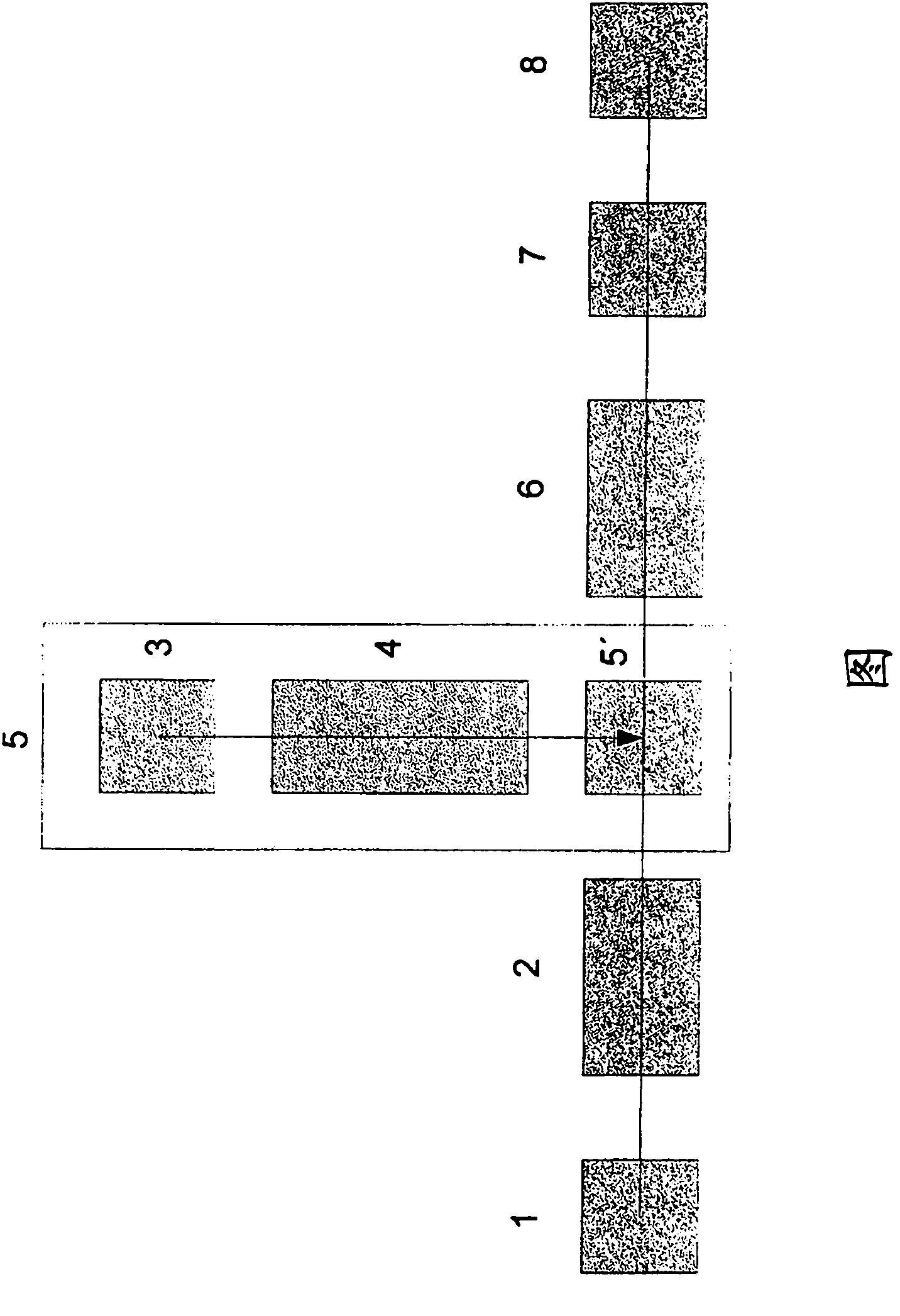

[0035] The supply of the wire to be coated takes place via a unit 1 . The bare wire is transported to unit 2 where the wire is pre-treated. The pretreated wire is then guided through unit 5 . The application of the insulating coating material takes place in this unit.

[0036] The unit 5 is designed as a so-called transverse spray head. The transverse nozzle is connected to the extruder 4 . In the extruder 4 the plastic pellets from the storage container 3 are melted. The melted plastic pellets are then evenly applied to the wire by a transverse spray head.

[0037] The transverse jet 5 comprises a connection to the extruder outlet, a wire guide system centrally arranged at right angles or at an angle to the extruder screw axis.

[0038] The material is applied to the wire around the wire guide system by means of distribution channels and nozzle guide means.

[0039] The distribution channels are designed in such a way that the material is distributed evenly around the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com