Backwater valve and fluid power energy-saving water pump

A technology of fluid power and reverse flow valve seat, which is applied in the direction of pressure pumps, components of pumping devices for elastic fluids, liquid fuel engines, etc., and can solve problems such as small compression force, so as to increase gas compression force and improve ejection The effect of speed and water output and increase of head height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

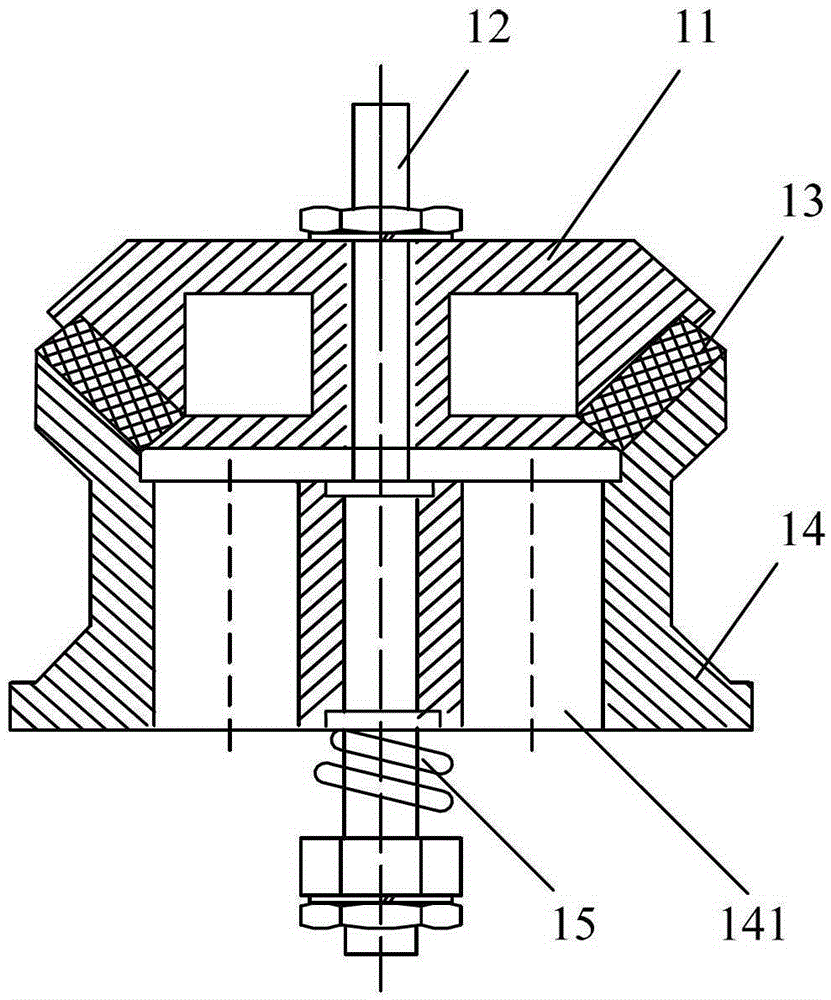

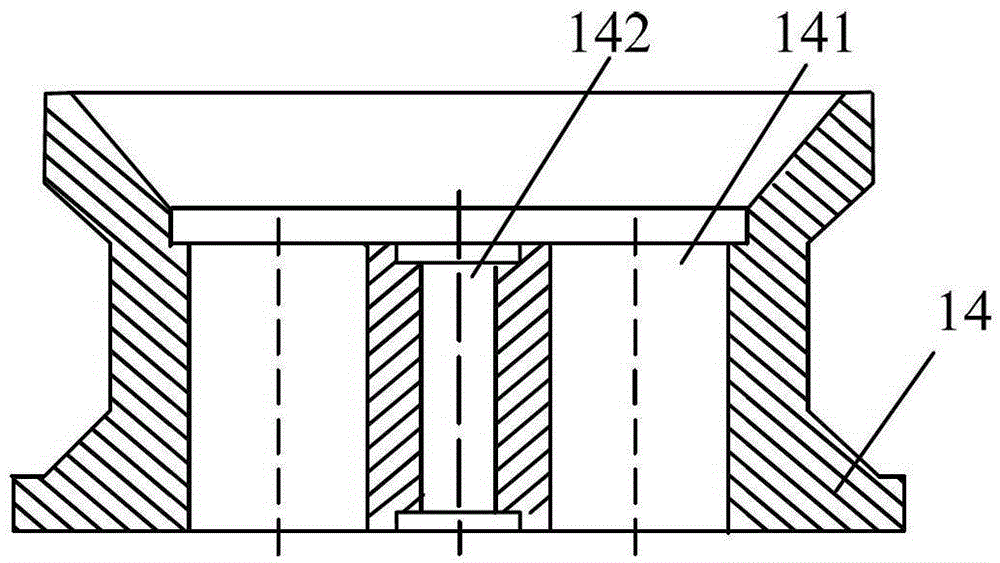

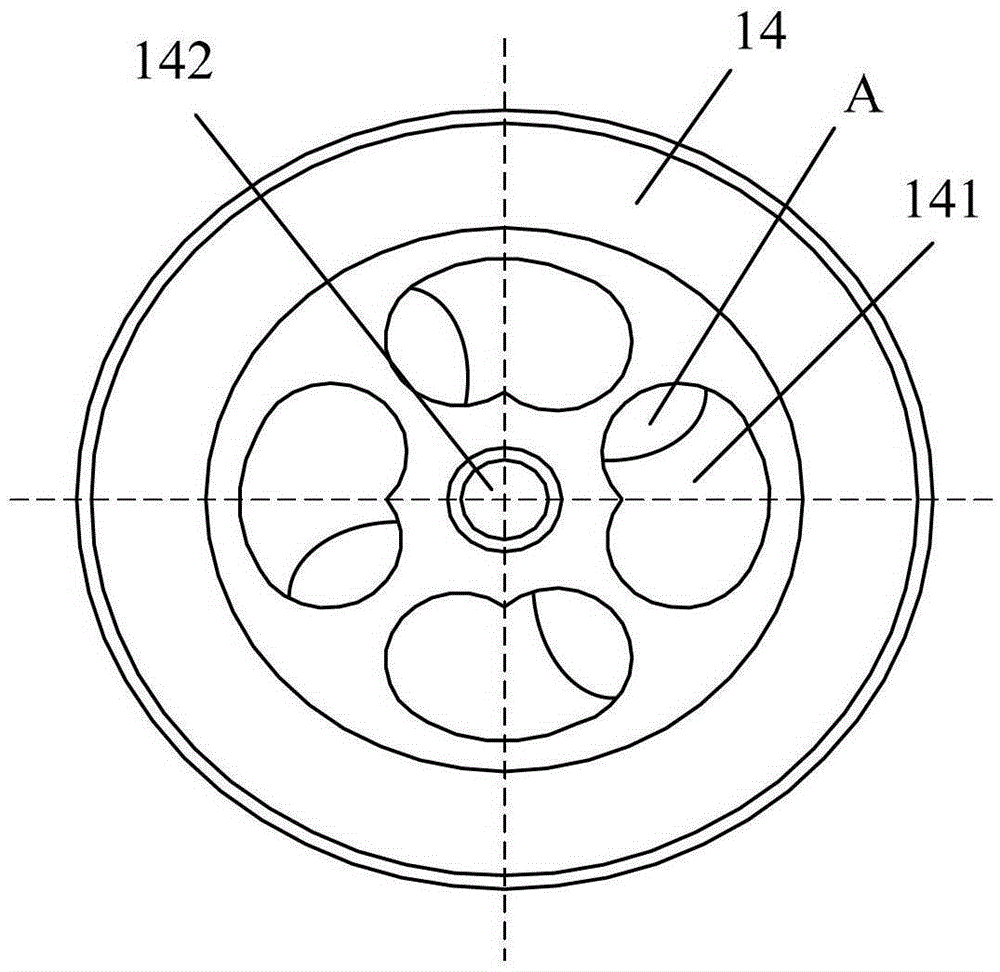

[0020] figure 1 It is a sectional view of the reverse water valve provided in the first embodiment of the present invention, figure 2 The front view of the reverse water valve seat provided in the first embodiment of the present invention Figure 1 , image 3 It is a top view of the reverse water valve seat provided in the first embodiment of the present invention, Figure 4 The front view of the reverse water valve seat provided in the first embodiment of the present invention Figure II , Figure 5 The front view of the reverse water valve seat provided in the first embodiment of the present invention Figure 3 , Image 6 The three-dimensional view of the reverse water valve seat provided in the first embodiment of the present invention Figure 1 , Figure 7 Stereoscopic view of the reverse water valve seat provided for the first embodiment of the present invention Figure II , Figure 8 The three-dimensional view of the reverse water valve seat provided in the fir...

Embodiment 2

[0030] Figure 9 It is a schematic cross-sectional structure diagram of the hydrodynamic energy-saving water pump provided in the second embodiment of the present invention. The fluid power energy-saving water pump can include a reverse water valve 1, a pump body 2, an air tank 3 and an impact valve 4, wherein the pump body 2 includes a water inlet, a reverse water opening and a water outlet, and the water outlet is fixedly provided with an impact valve 4. The tank 3 and the pump body 2 communicate with each other through the reverse water valve 1 at the reverse water port. like Figure 9 In the sectional view of the energy-saving water pump shown, the left side of the pump body 2 is the water inlet, the right side is the drain outlet, and the top is the reverse water outlet. The pump body 2 also includes a pump body back cover 21 . At the water outlet, the pump body back cover 21 is fixedly connected with the pump body 2 through bolts, and the impact valve 4 is fixed inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com