Nickel-based selective hydrogenation catalyst, preparation method and application thereof

A hydrogenation catalyst and selective technology, which is applied in the field of petrochemical industry, can solve the problems of rapid activity decline, frequent catalyst regeneration, and rapid increase of inlet temperature, etc., and achieves easy operation, stable selectivity and activity, and simple and easy preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

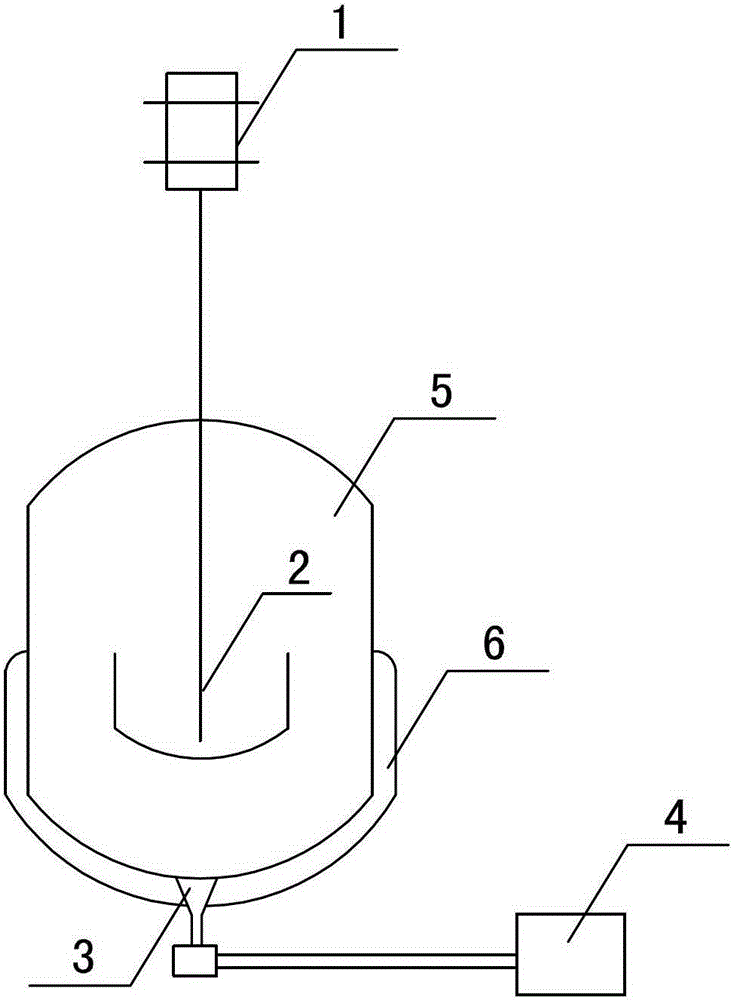

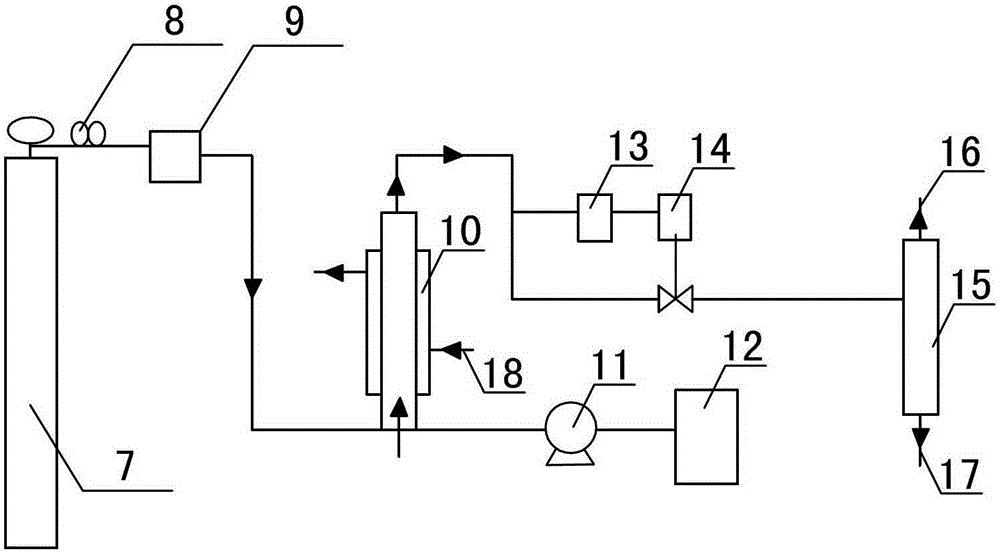

Image

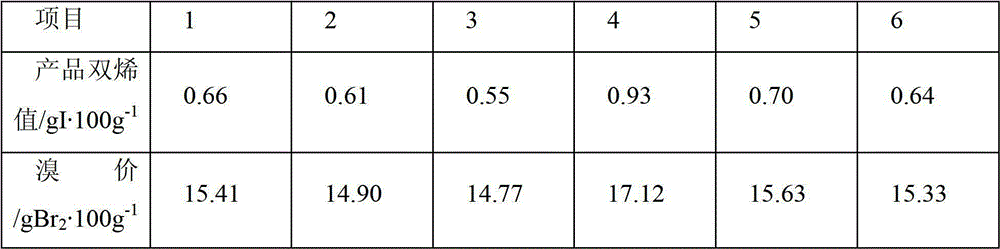

Examples

Embodiment 1

[0030] Add 600g sodium metaaluminate (Al 2 o 3 ≥24.0%), heated to 40°C, called solution A.

[0031] Add 800g of aluminum sulfate to 2L of water and raise the temperature to 40°C, called solution B.

[0032] Add solution B dropwise to solution A, and the dropping time is controlled at 30 minutes, and stir while adding dropwise, so that solutions A and B undergo a precipitation reaction.

[0033] After the dropwise addition, keep stirring for 15 minutes, then turn on the ultrasonic wave, control the frequency to 20Khz, and the sound intensity to 0.5W / cm 2 , static aging for 60 minutes.

[0034] The reactant was filtered and washed, and the temperature of the washing water was kept at 40°C.

[0035] Alumina hydrate was obtained, and the alumina hydrate was dried at 120° C. for 24 hours, and it was determined to have a pseudo-boehmite structure by X-ray diffraction.

[0036] After the prepared pseudo-boehmite was roasted at 500°C for 3 hours, the specific surface area was det...

Embodiment 2

[0043] Add 600g sodium metaaluminate (Al 2 o 3 ≥24.0%), heated to 40°C, called solution E.

[0044] Add 800g of aluminum sulfate to 5L of water and heat up to 50°C, called solution F.

[0045] Add the solution E dropwise to the solution F, the dropping time is controlled at 30 minutes, and stir while adding dropwise, so that the solutions E and F undergo a precipitation reaction.

[0046] After the dropwise addition, keep stirring for 15 minutes, then turn on the ultrasonic wave, control the frequency to 50Khz, and the sound intensity to 0.45W / cm 2 , static aging for 60 minutes.

[0047] The reactant was filtered and washed, and the temperature of the washing water was kept at 50°C.

[0048] Alumina hydrate was obtained, and the alumina hydrate was dried at 120° C. for 24 hours, and it was determined to have a pseudo-boehmite structure by X-ray diffraction.

[0049] After the prepared pseudo-boehmite was roasted at 500°C for 3 hours, the specific surface area was determin...

Embodiment 3

[0056] Add 400g sodium metaaluminate (Al 2 o 3 ≥41.0%), heated to 60°C, called solution I.

[0057] Add 850g of aluminum sulfate to 3L of water and heat up to 60°C, called solution J.

[0058] Add solution J dropwise to solution I, and the dropping time is controlled at 45 minutes, while stirring while adding dropwise, so that solutions I and J undergo a precipitation reaction.

[0059] After the dropwise addition, keep stirring for 30 minutes, then turn on the ultrasonic wave, control frequency 35Khz, sound intensity 0.4W / cm 2 , static aging for 120 minutes.

[0060] The reactant was filtered and washed, and the temperature of the washing water was kept at 60°C.

[0061] Alumina hydrate was obtained, and the alumina hydrate was dried at 125° C. for 24 hours, and it was determined to have a pseudo-boehmite structure by X-ray diffraction.

[0062] After the prepared pseudo-boehmite was roasted at 500°C for 3 hours, the specific surface area was determined to be 363m2 by ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com