Zinc arsenide production equipment

A zinc arsenide and equipment technology, which is applied in the field of zinc arsenide production equipment, can solve the problems of low zinc arsenide purity, long production time, short furnace life, etc., and achieves simple detection and maintenance, high production efficiency, The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

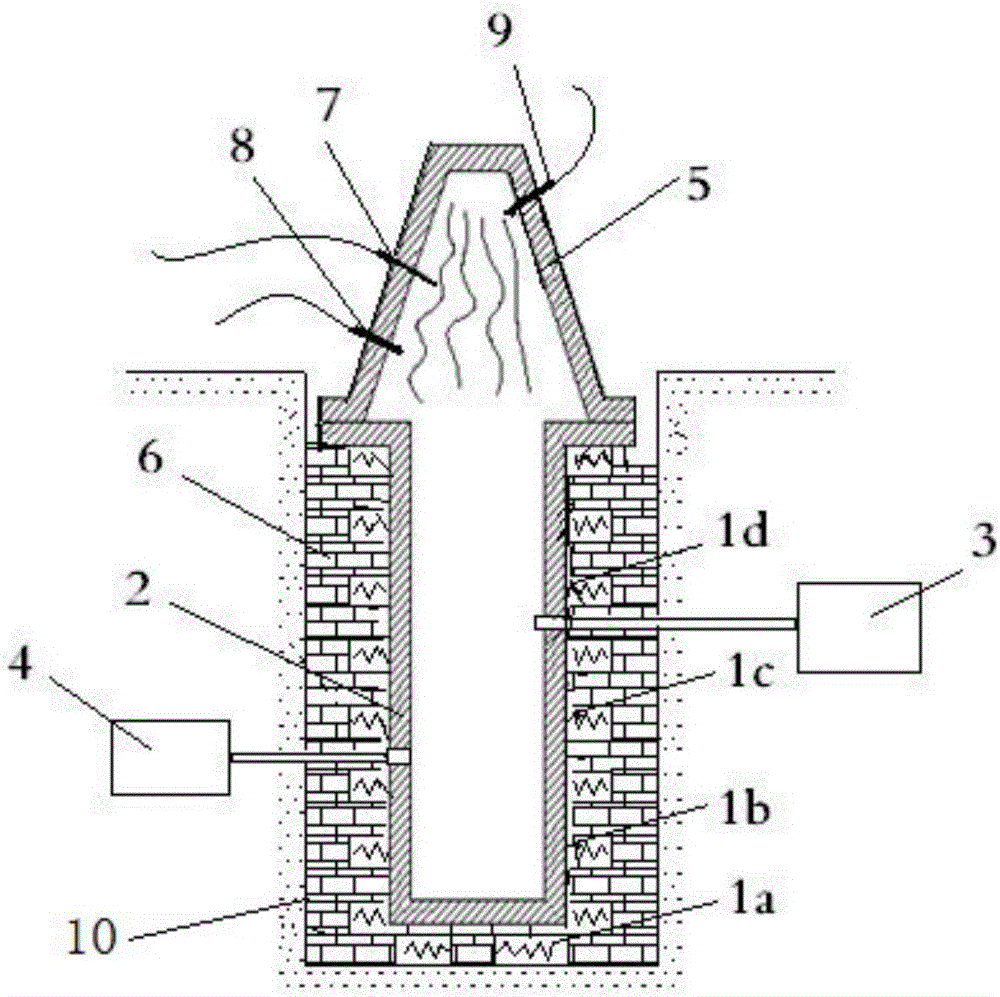

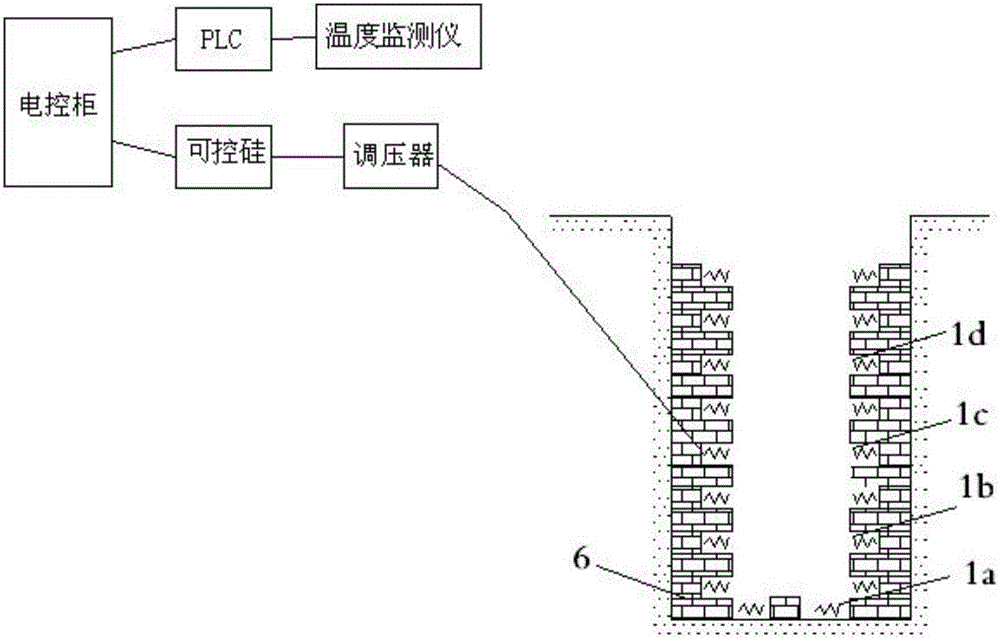

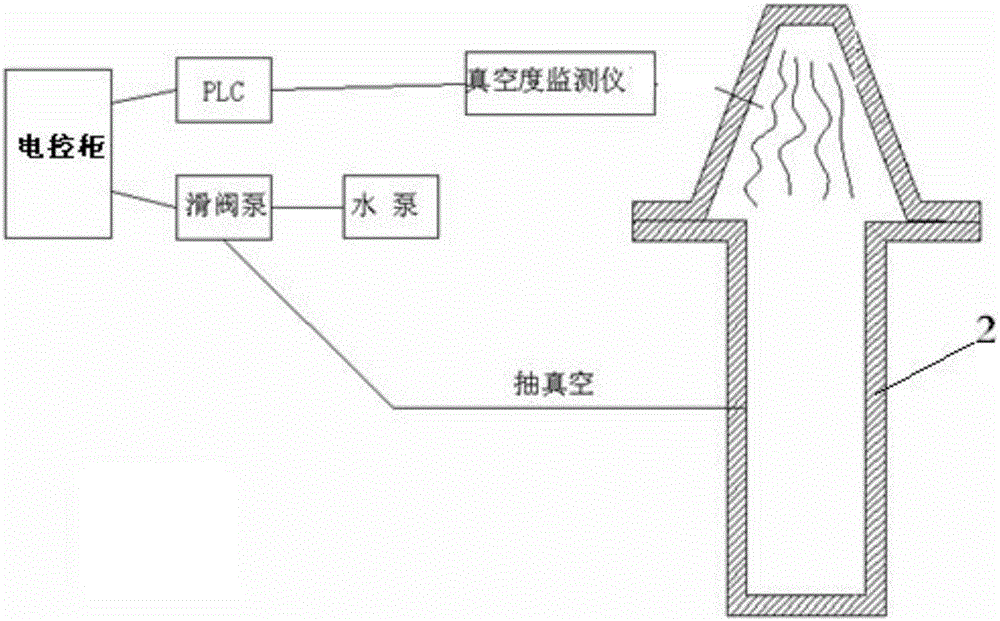

[0017] Such as figure 1 The equipment for the production of zinc arsenide shown is a well-type structure, including an electric heating system, a furnace 2 that can be placed in the heating system, a vacuum system 3 connected to the furnace, and an atmosphere protection system 4. The cover is in the The zinc arsenide collector 5 on the top of the furnace. The furnace is made of steel mixed with metals with high thermal conductivity. The furnace has been carburized and surface boronized, and has the characteristics of fast heating, resistance to metal arsenic, zinc corrosion, and high pressure. The volume of the furnace can be 400L-1000L, and the weight of zinc arsenide that can be synthesized at one time is 200-1000Kg. Furnace life is 1 to 3 years. The strength of the furnace can be guaranteed at 1000°C, and it can be lifted by a crane. The steel material mixed with high thermal conductivity metal is to mix iron powder, copper powder, silver powder and carbon powder accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com