A kind of slag cloth separator

A slag cloth separation mechanism and separator technology, applied in grain processing and other directions, can solve the problems of messy slag stacking, difficult to separate, and cannot be completely removed, and achieve the requirements of reducing labor intensity, saving labor, and ensuring safety and hygiene requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

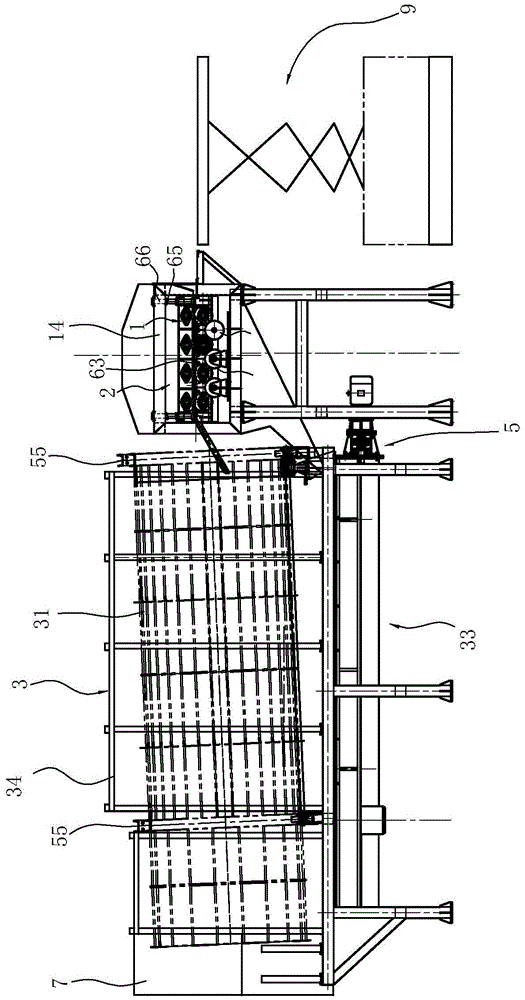

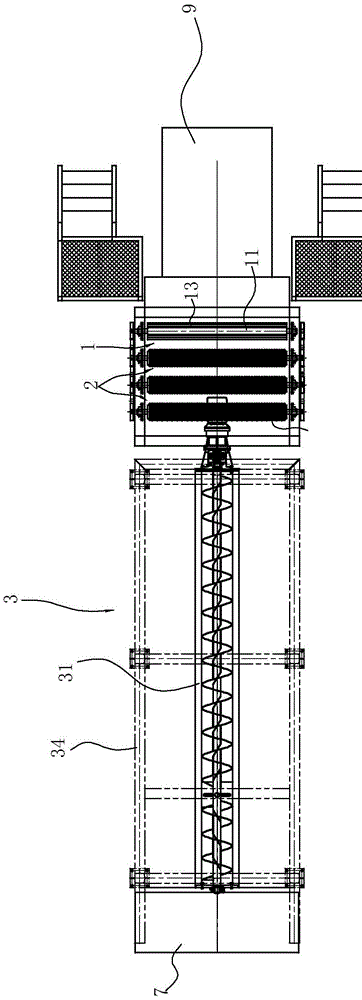

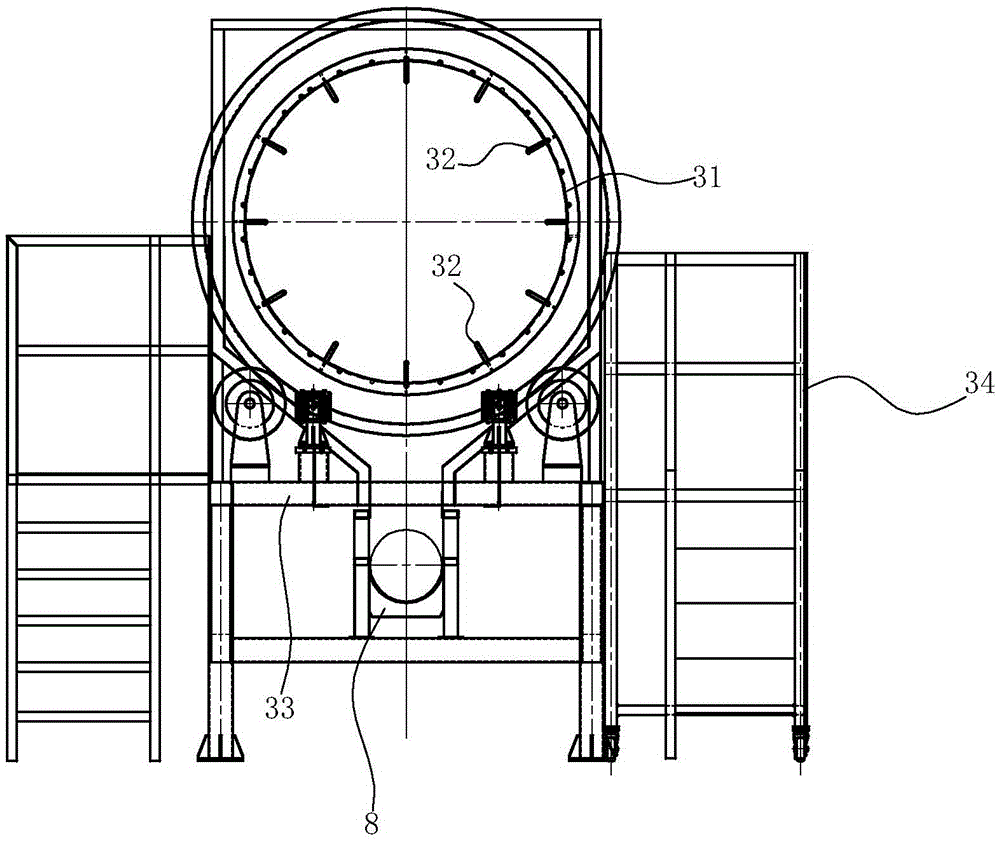

[0032] like Figure 1 to Figure 9 As shown, the slag cloth separator includes a lifting platform 9 , a cloth feeding mechanism 1 , a rolling mechanism 2 and a slag cloth separating mechanism 3 arranged in sequence along the running direction of the slag cloth.

[0033] Wherein, the lifting platform 9 is arranged upstream of the cloth feeding mechanism and downstream of the pressing mechanism, and is used for placing and adjusting the height of the moromi package (not shown in the figure), so as to facilitate delivery to the cloth feeding mechanism 1 . Lifting platform 9 can be driven up and down by hydraulic cylinder, also can adopt electric drive to go up and down.

[0034] The cloth feeding mechanism 1 and the rolling mechanism 2 are arranged on the first frame 14. The cloth feeding mechanism 1 includes two upper cloth feeding rollers 11 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com