A device for removing antimony from yellow phosphorus

A technology for removing antimony and yellow phosphorus, applied in phosphorus compounds, inorganic chemistry, non-metallic elements, etc., can solve the problem of not using antimony removal reaction equipment, and achieve the effects of simple structure, improved purity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

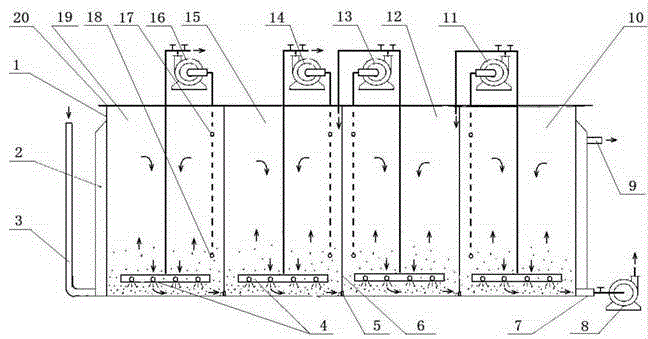

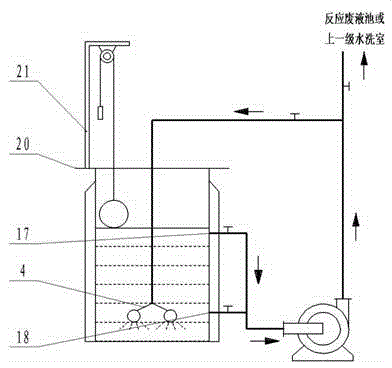

[0026] A yellow phosphorus deantimony device, comprising a deantimony tank 1, a liquid level gauge 21, a circulation pump and a discharge pump 8; a jacket 2 is arranged outside the deantimony tank 1; a jacket 2 is arranged under one end of the jacket 2 There is a water inlet pipe 3, and an outlet pipe 9 is arranged above the opposite end of the jacket 2 water inlet pipe 3; what leads into the jacket 2 is hot water. The top of the deantimony tank 1 is provided with a cover plate 20, half of the cover plate 20 is made of glass material, and half is made of stainless steel and acid-resistant material. The outlet pipe 9 of the jacket 2 is provided with a discharge port 7 below; the discharge port 7 is connected to the discharge pump 8; the deantimony tank 1 is separated by a partition plate 6, and a deantimony chamber 19 and The two washing chambers are the primary washing chamber 15 and the secondary washing chamber 12 respectively. Each chamber is provided with an independent l...

Embodiment 2

[0032]A yellow phosphorus deantimony device, comprising a deantimony tank 1, a liquid level gauge 21, a circulation pump and a discharge pump 8; a jacket 2 is arranged outside the deantimony tank 1; a jacket 2 is arranged under one end of the jacket 2 There is a water inlet pipe 3, and an outlet pipe 9 is arranged above the opposite end of the jacket 2 and the water inlet pipe 3; water vapor is passed into the jacket 2. The top of the deantimony tank 1 is provided with a cover plate 20, half of the cover plate 20 is made of glass material, and half is made of stainless steel and acid-resistant material. The outlet pipe 9 of the jacket 2 is provided with a discharge port 7 below; the discharge port 7 is connected to the discharge pump 8; the deantimony tank 1 is separated by a partition plate 6, and a deantimony chamber 19 and The three washing chambers are respectively the primary washing chamber 15 , the secondary washing chamber 12 and the tertiary washing chamber 10 . Each...

Embodiment 3

[0038] A yellow phosphorus deantimony device, comprising a deantimony tank 1, a liquid level gauge 21, a circulation pump and a discharge pump 8; a jacket 2 is arranged outside the deantimony tank 1; a jacket 2 is arranged under one end of the jacket 2 There is a water inlet pipe 3, and an outlet pipe 9 is arranged above the opposite end of the jacket 2 and the water inlet pipe 3; water vapor is passed into the jacket 2. The top of the deantimony tank 1 is provided with a cover plate 20, half of the cover plate 20 is made of glass material, and half is made of stainless steel and acid-resistant material. The outlet pipe 9 of the jacket 2 is provided with a discharge port 7 below; the discharge port 7 is connected to the discharge pump 8; the deantimony tank 1 is separated by a partition plate 6, and a deantimony chamber 19 and The three washing chambers are respectively the primary washing chamber 15 , the secondary washing chamber 12 and the tertiary washing chamber 10 . Eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com